Metalworking machines

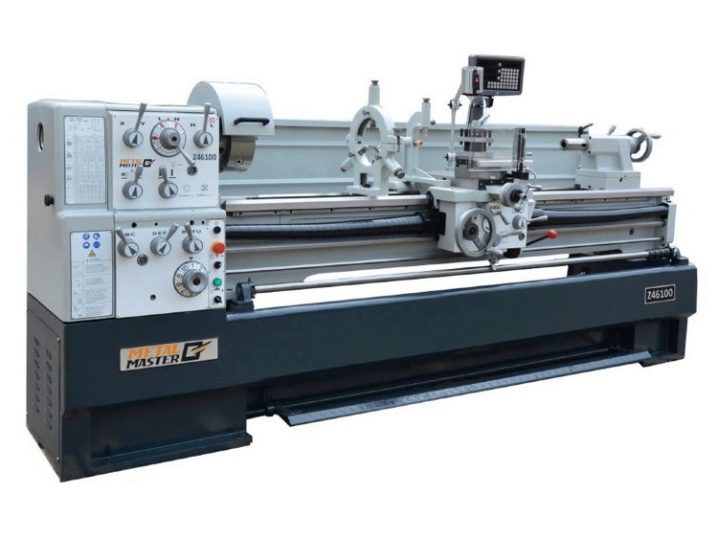

Metalworking machines are one of the most important types of industrial equipment. Noteworthy is the technique of the Metal Master brand and other manufacturers, especially the beading machines for sheet metal, punching and other types. And also it is worth taking a closer look at spare parts for metalworking machines.

Views

By appointment

Metalworking machines can be designed for:

-

drilling;

-

peeling;

-

polishing;

-

sharpening;

-

machining of parts of toothed and threaded products;

-

milling;

-

a number of other manipulations.

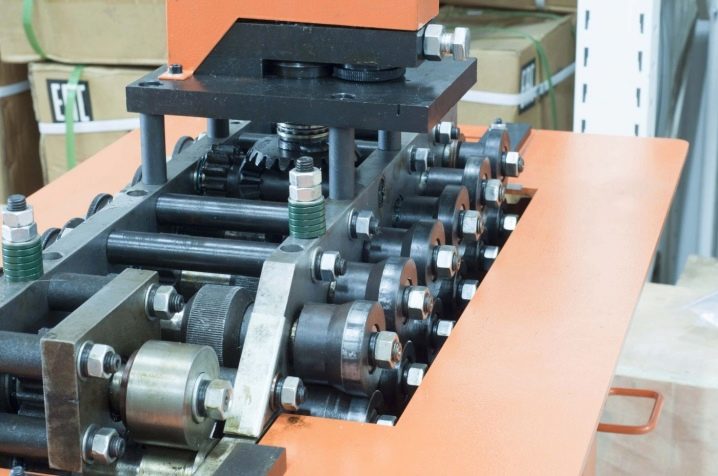

Metalworking machinery can be used to make pipes. This goal is successfully achieved with the use of special rollers. Profile bending systems are also suitable for the production of picket fences. Steel strips of measured length or strips obtained from galvanized cold-rolled alloy are taken as a basis for work. The estimated thickness of the raw material is usually 4-6 mm.

The machines can work both in manual and semi-automatic modes.

By specialization level

A machine capable of performing several different manipulations is considered universal. It is suitable for a wide range of parts. Apparatus that are suitable for the production of a narrow range of parts are recognized as specialized. Their configurations should be the same or similar, but the dimensions may vary. Most often we are talking about bearing rings, stepped shafts and the like.

Special machines are only suitable for machining parts of the same size. Sometimes they produce only one position of the technological nomenclature. But the quality of manipulations increases significantly.

Often such devices are produced according to individual orders. Serial production is rarely practiced due to low profitability.

By the degree of processing accuracy

Simple metalworking machines are categorized as "H". This equipment is of a normal level of accuracy. Almost all mass-produced entry-class devices belong to this group. More precise equipment belongs to the "P" group. The technique of the "H" group is taken as a basis, however, the accuracy of single parts can be increased.

The classification of metalworking machines also provides for the position "B", or high-precision equipment. Here it is already impossible to be limited by increased tolerances. Almost always, the most critical details are made according to individual projects. There are high demands on the assembly and adjustment of such equipment. Additionally, it is worth mentioning machines "A" - that is, especially high precision and "C" - that is, master-level. On the equipment of class "C" usually already advanced specialists work.

By level of automation

Everything is pretty simple here:

-

manual equipment requires constant attention of workers in any operation;

-

semiautomatic devices imply a partial execution of technological manipulations, first of all, the installation of a part and its removal;

-

automatic machines - machines that perform work in strict accordance with the parameters set by the personnel;

-

CNC metal-cutting systems (instead of setting individual parameters, a complex program is used in the form of numerical parameters);

-

the pinnacle of excellence are flexible automated modules.

The beading machine for sheet metal is used for the production of air ducts and roofing sheets. Such devices apply projections and form continuous recesses in the metalwork. They mainly process relatively thin sheets. Working with thick metal would be very difficult. The punching metalworking machine also deserves attention.

Universal models of such equipment are suitable for both workshops and small factories. The differences between the two relate largely to the processing height. An important characteristic is also the changeover time of the tooling. Some models are capable of punching holes in pipes. Advanced samples throw error messages.

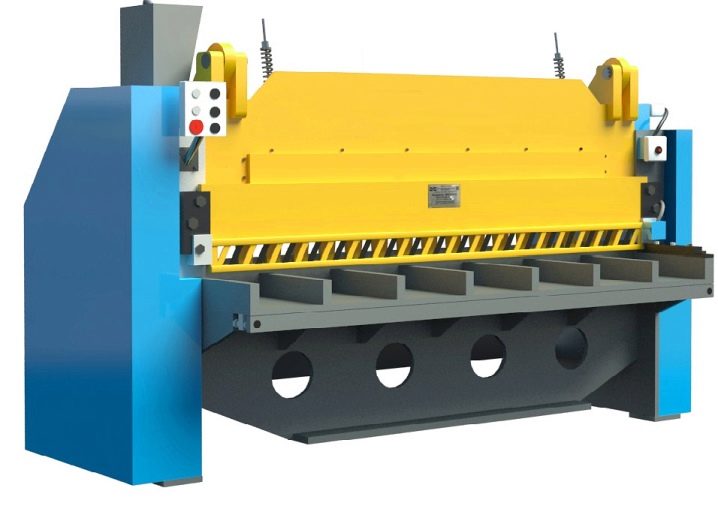

Metal shearing machines are often used to get workpieces exactly to size. They are suitable for sheet metal and steel profiles. This technique can be seen in small manufacturing plants and on construction sites. It is also used in mechanical engineering. We are talking primarily about mechanical and electromechanical guillotines.

Hydraulic machines can be used to punch holes in pipes. This method allows you to minimize the amount of damage in the workpiece and reduce the cost of manipulation. This type of equipment is often easier to automate and safer. Electricity consumption is greatly reduced. The value for money will be optimal.

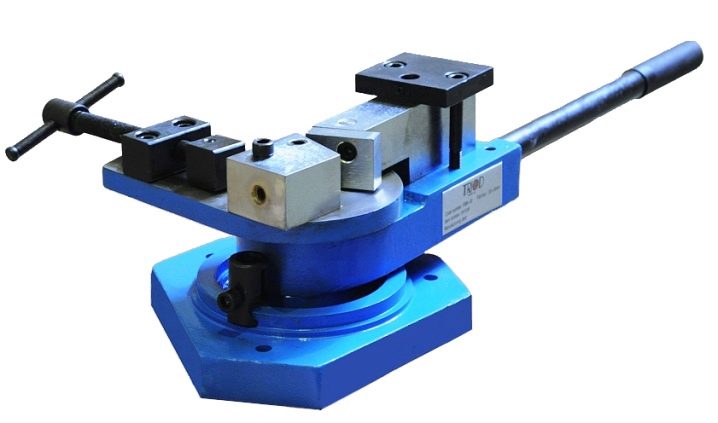

Machines for bending steel strips or reinforcement are quite widely demanded. The simplest of them are designed for manual work. An important part of the devices are protractors, with the help of which the required angles of processing are set. Sheet metal can be bent on a universal bending machine using a die and punches. There are also swivel devices.

Chamfering machines are in demand in almost any industry where welding is used. Basically, we are talking about the processing and finishing of sheet material. Such equipment is also used when obtaining furniture elements and furniture parts. With the help of bevelling equipment, support and bridge structures are erected. Some models even allow countersink holes.

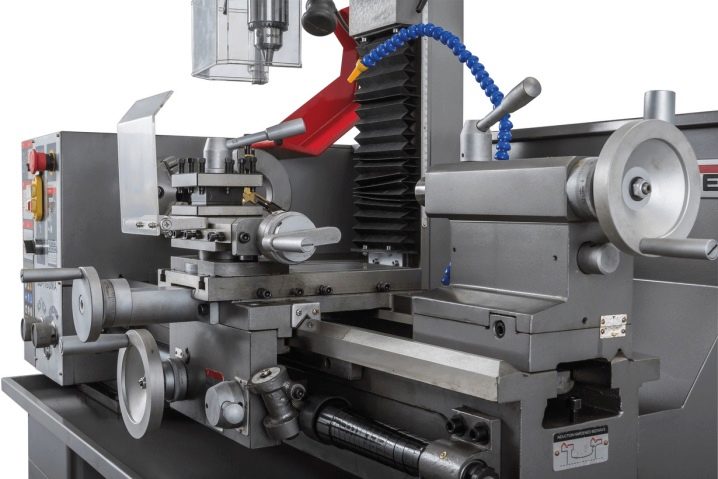

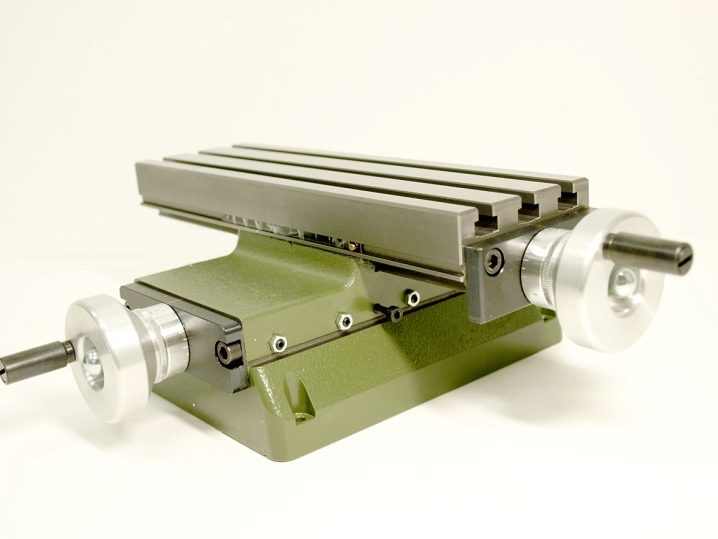

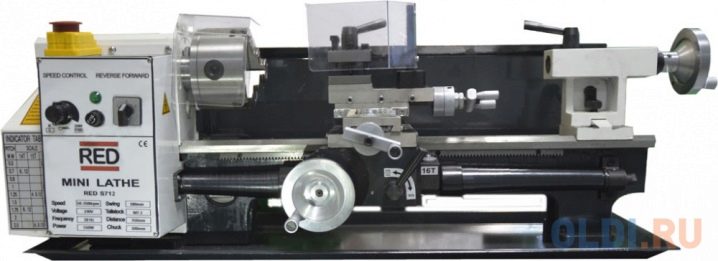

All described metalworking machines can also have a desktop format. The performance in this case will be less. However, the usability will be much better. A coordinate machine is a metal-working machine that is distinguished not by any specific type of manipulation, but by the fact that it can work in at least 3 axes.

5-axis systems are becoming more and more widespread, suitable for the production of a large number of complex parts.

Even more advanced devices have tilt and swivel modes. As a result, the processing accuracy is significantly increased. In the metallurgical and metalworking industries, special rolling machines are actively used. In addition to changing the shape of the passed sheet, such equipment has a positive effect on its strength and density. The rollers rub and close all cracks and gaps. Before processing, the metal must be heated.

The press-rolling machine for rotary drawing is popular. Some models of such equipment can be equipped with CNC systems. It produces thin hollow parts in the shape of a body of revolution. The pressure is often in the longitudinal or radial plane. The roller moves in different directions as needed. Processing is usually carried out in several passes.

Marking

These symbols are designed for accurate specification of performance. The structure is quite simple:

-

the first digit shows the group of application of the metalworking machine;

-

the second character corresponds to the type of model;

-

the final figure illustrates the standard size;

-

with the help of alphabetic characters, they indicate the specifics of the equipment and its auxiliary functionality.

Spare parts and components

For metalworking machines, you can buy:

-

tool holders;

-

upper calipers;

-

drums;

-

uterine nuts;

-

movable lunettes;

-

hydraulic preselector;

-

protective screens;

-

tapered rulers;

-

overtaking clutches;

-

tailstock quill;

-

reducers and gears for them;

-

pulleys and spindles;

-

vibration supports;

-

shafts;

-

friction discs and a number of other parts.

Popular manufacturers

Equipment of the Metal Master brand has long been distinguished due to its special reliability. The assortment is constantly expanding. For the manufacture of machine tools, this company uses the most modern production facilities in different countries. There are both desktop and full-fledged universal devices with high perfection. The service life is quite decent, safety is also provided.

But for metalworking, you can use equipment from other companies. Walter is confidently leading among the world leaders. This company has been operating since 1919 and has amassed a tremendous amount of experience. In addition to production, Walter also provides technical advice. She has a large number of distributors in different parts of the world.

Stalex machines are of high quality. They are quite reliable and technologically advanced. The workmanship of units and parts is very high. These assemblies meet the strictest quality standards. The company offers bending machines, guillotines and other equipment.

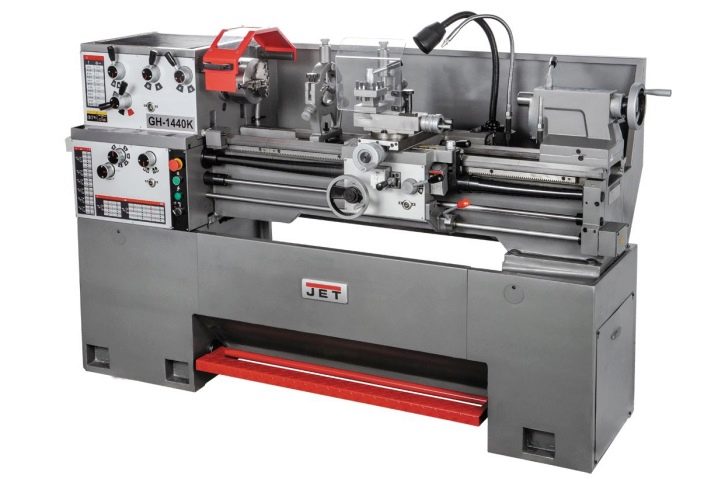

The JET company has also proven itself from the best side. Its range includes CNC turning and milling equipment. The firm cooperates with a large Swiss manufacturer JPW Group.

Solid warranty obligations and service organization testify in its favor. There are also quite a few JET service points in Russia.

In Russia, it is worth noting products:

-

LSP (Lipetsk);

-

F. O. R. T. (large holding);

-

Tver enterprise (supplying software-controlled systems);

-

Ulyanovsk Machine Tool Plant (one of the most modern domestic enterprises);

-

group STAN (the largest domestic manufacturer).

Quite modern products are produced at SMZ. This enterprise is actively cooperating with Russian Railways. The company has been operating since 2005. She makes pipe benders and hydraulic presses. The Sverdlovsk Machine-Building Plant supplies its equipment to the military-industrial complex.

In addition to the named companies, stand out:

-

JSC "MEMP";

-

JSC "Stankotech";

-

BODA;

-

"Caliber";

-

Alapaevsk Machine-Tool Plant;

-

JSC "TsNITI";

-

DMTG;

-

SMTCL (the world's largest manufacturer);

-

DBHH.

The comment was sent successfully.