All about cold forging machines

Cold forging machines are specialized equipment with which you can create beautiful and high-quality metal products. A characteristic feature of such devices is the possibility of installation at home and independent production. There is a wide variety of powerful and durable devices on the market.

Views

For more efficient and faster processing of metal products, manufacturers produce various types of cold forging machines, which differ in terms of functional and operational characteristics. A detailed overview of each variety will allow you to quickly select the necessary equipment and avoid most of the mistakes made by beginners.

The main types of equipment for art forging machines.

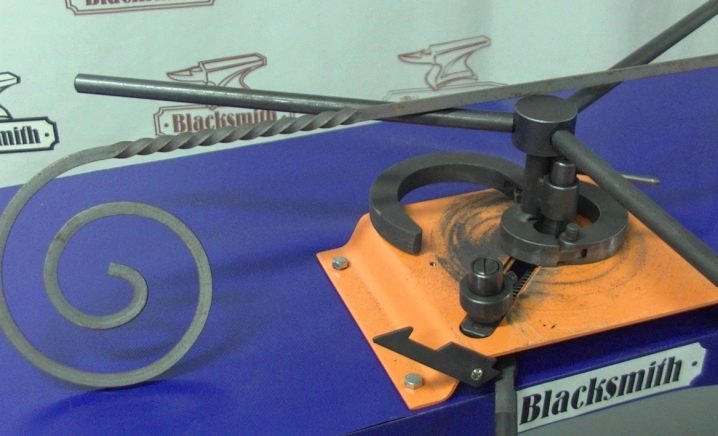

- "Snail". The most versatile device for the production of spiral metal elements. This equipment is made of a cast base, which allows it to be used for a long time. In this variety, the raw material is always twisted in a spiral. The blacksmith can use both hot profiles or rods, and cold ones.

- "Gnutik". It is a classic version of the cold machine. Using this equipment, the blacksmith can make corners of any shape and size. The design is based on a bending die with an additional eccentric drive. It is considered a multifunctional device due to the possibility of using additional parts.

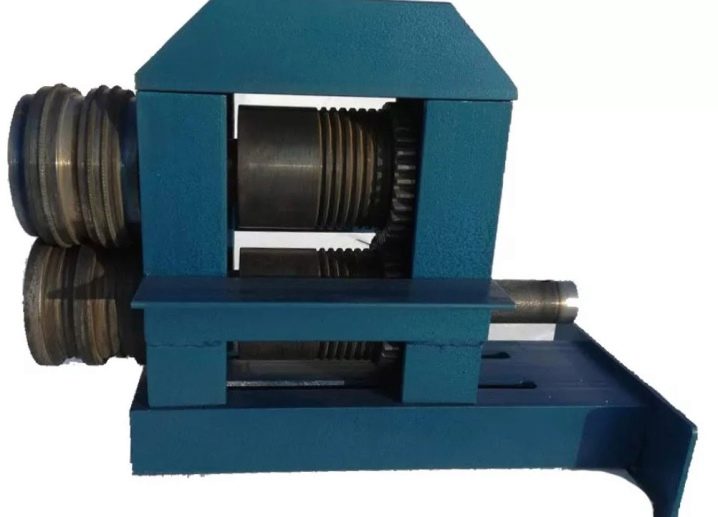

- "Wave". A modern type of easel equipment that allows you to create twisted patterns or curls with a small and solid core. The main elements are alloy wheels, which are attached to the metal structure with high-strength bolts.

If desired, the blacksmith can choose the distance between the discs.

- "Goose foot". Classic machine for cold and hot rolling of integral parts of a profile pipe. Its use allows you to achieve highly artistic forging in the form of an even wrinkle. Equipped with two identical shafts. The variety is distinguished by a high speed of work - about 4-5 seconds per piece.

- "Globe". A distinctive feature is the presence of a special handle, with the help of which the blacksmith gives the metal product the desired shape. Using this variety, you can create templates for forging.

In addition to the varieties described above, any machine tools for metal are conventionally classified into 4 groups.

-

Torsion bars. For longitudinal twisting of metal profiles or rods.

-

Twisters. For the purpose of forming spirals and curls.

-

Stamping. For flattening rods and forming patterns, feet or clamps.

-

Bending. To create various zigzags or waves.

Multifunctional and technological cold forging machines are equipment with many advantages. The use of such devices makes it possible to significantly facilitate human labor, obtain better parts and accelerate production technology.

Gearboxed machines do not require a direct connection to the mains. Due to this feature, the master can save a significant amount on electricity. Depending on the type of power supply, the equipment is also conventionally classified into manual and electrical mechanisms.

In addition to specialized equipment, you must also have a set of the following tools: a globe for an arc, a metal element "Flashlight", a volumetric box and consumables.

Manual

Hand-held machines are specialized devices that function due to mechanical force applied directly by the craftsman. The design mainly consists of levers, which allows for better distribution of kinetic energy. This variety is often installed in small workshops.

The main advantages of hand-held machines:

-

work without the need to connect to the mains;

-

no requirement for specialized skills or qualifications;

-

the possibility of placing in a garage or in the country;

-

easy transportation and compactness;

-

high liquidity in case of resale.

An equally important advantage of this type is the ability to connect additional functional elements. Such a machine can be easily disassembled, which allows you to change its design features for yourself. The advantage is also the low cost - from 7 to 20 thousand rubles, depending on the type of mechanism.

Electrically driven

The main advantage of electrically driven machine tools is the ease of human labor. The presence of an electrical mechanism in the design of the equipment allows for much faster and more accurate production of parts. A similar device is usually used for mass production.

In addition to the high working speed, the electric drive allows for a smoother bending. The disadvantage of this type is the high cost, which depends on the availability of additional features or the actual power of the engine.

Universal electrical equipment can cost from 200 to 300 thousand rubles. There are also more expensive models on the market that are used in the industrial field. Usually, such devices are not suitable for home use due to the high price and size.

Top Models

For a machine to be highly efficient and productive, you need to know which companies supply the highest quality equipment. Despite the wide variety of manufacturers, only a small proportion of the market is used by blacksmiths.

The most popular company is considered Chinese specialist equipment manufacturer BlackSmith... This brand not only manufactures machine tools, but also hydraulic presses, forming devices and many other components.

Here is a rating of the models of this manufacturer.

- M3-G. It is usually used for various works with rods up to 12 mm. Can be used to quickly bend metal strips and form rings.

- M3-V1. Manual type equipment, with which you can create high-quality curls of various shapes. This device uses metal strips up to 40x5 mm in size and rods with a thickness of 12-13 mm.

- M04B-KR. With this machine, the blacksmith is able to quickly produce strong baskets or twisted patterns from metal rods, the cross-section of which reaches 14-16 mm.

- UNV3-02. Universal equipment with which you can perform almost all popular types of work with metal raw materials.

- PS-14. It is used for twisting metal structures without heating. Allows to process copper, St3 steel and any other soft materials.

- UB-100. It is mainly used on construction sites and locksmiths. Designed for bending mild steel squares, strips or rods.

In addition to the Chinese manufacturer, you can purchase domestic equipment from Azhurstal. Available devices are versatile, practical and very low prices.

Here are the most popular models.

- "Openwork-mini". Despite its compactness, this equipment copes well with metal rods up to 15 mm thick.

- "Azhur-1". Quite a productive model, using which it is possible to produce up to 5-6 thousand bent metal products per month.

- "Azhur-2". Great for creating volumetric patterns and rolled rectangular or angular shapes.

- "Azhur-Universal". The device is presented in the form of a rolling and bending machine, which greatly increases the versatility.

German machine tools are also very popular. The most famous company from Germany is production organization Habosupplying high quality equipment for over 20 years. Such devices are characterized by minimal noise, economy and almost complete absence of vibrations.

In addition to the varieties described above, experts also recommend modern machine "Maxim" 4 in 1. This equipment is highly effective in creating awnings, gates, stairs, barbecues or fences. The main advantages of the Russian machine tool are: high speed of operation, reliability and durability of the component parts.

Any sudden movements must be avoided when operating the machine. Otherwise, the equipment will fail pretty quickly. And you should also carefully check the reliability of structural elements before purchasing a specialized device.

How to do it yourself?

In addition to purchasing ready-made equipment, anyone can independently make a cold forging machine. The manufacture of the device does not require specialized skills. It is especially important to follow the guidelines below carefully to avoid most of the shortcomings or mistakes.

The first thing that needs to be done before the production of equipment is to develop a drawing on which the machine and its key nodes or connections should be accurately depicted. The construction plan also indicates the dimensions and additional fasteners.

A step-by-step guide to making a torsion-type machine.

-

Prepare an overall metal bed. Fix the channel with any welding device.

-

Install a specialized vise on one end of the channel.

-

Attach an additional clamp with movable rollers.

Clamping equipment is best made of a strong alloy, and there should be holes for fixing bolts.

- After completing the above steps, it is necessary to weld the handles onto the roller bushings. To improve safety and ease of use, the vise and bushings should be placed at the same level.

To make the simplest home machine "Gnutik", weld metal shafts on a steel plate and make a rectangular hole between them. Further, a movable stop is attached to the center of the structure - an element necessary for choosing an angle when bending. It is recommended to use parts made of tool steel in the production of Gnutik.

For the manufacture of the multifunctional machine "Snail", you must use one of the following methods.

- The easy way. Draw the outlines of the snail on a metal sheet in the desired size and shape. Cutting of structural elements is carried out using specialized equipment with a welding power supply. Further, all parts are fixed on the table in accordance with the operational features.

- Removable "Snail". In this case, removable equipment is manufactured with a large number of metal bolts. To do this, make 4 threaded holes in the workpiece. With their help, the blacksmith will be able to change the radius of metal products by tightening the bolts.

- Advanced way. To create a multifunctional and durable "Snail" yourself, you should take several prepared frames and connect them using fixing elements - bolts with small holes.Further, the main shaft of the equipment is formed, on which the working surface and additional sheets are installed.

For a detailed master class, see below.

After the "Snail" is assembled, it must be checked on rough blanks. Any structural elements should be secured using welding equipment that can withstand intense and prolonged loads.

The finished frame is always mounted on a movable shaft. Otherwise, the "Snail" will not be able to rotate, which reduces the usability.

The comment was sent successfully.