Features of multifunctional woodworking machines

Working with wood involves the use of special equipment, thanks to which you can process the material in different ways. We are talking about multifunctional machines that are offered on the market in several varieties, each type with its own characteristics and advantages. There are a number of criteria that should be considered when choosing such equipment. We would like to bring to your attention useful information, with the help of which you can familiarize yourself with the unit in more detail.

Description

Woodworking machines are used in enterprises of various sizes, while it is impossible to do without them in home workshops, because the equipment can be universal, which is one of the main advantages. Already from the name it becomes clear that the tool has a number of functions that allow you to solve certain tasks for the processing of natural wood. Thanks to various attachments, the material can be sawn, give it the desired size and shape. With the help of modern equipment, you can get elements for assembly structures and frames, furniture parts, window sets and much more. The products are offered with two drive options - electric and gasoline. The element is equipped with a special device that protects against the ingress of sawdust, thus, the operation of the equipment is safe and convenient.

It should be noted that the tool is offered in a wide range, can have different configurations and last for many years if used correctly. Such a machine can replace conventional planing dusty units, besides, using it, you can forget about additional expenses for drilling or grinding equipment.

It is the best choice for both a small home workshop and a large enterprise that handles wood on a large scale.

The main advantages of a multifunctional machine include its versatility, since it is capable of performing various tasks, which you can learn about below. At the same time, it does not take up much space, it is quite compact and easy to use. The design is made in such a way that the workpiece is easily and securely attached to it before starting the process. The machine will not emit unnecessary vibration, so the quality of work will be at the highest level. The master himself will enjoy the process, during which nothing threatens his health. The rigidity of the tool increases endurance when working with large wood products.

It should be noted that some machines provide the ability to connect a household vacuum cleaner for cleaning, and this is very convenient.

Species overview

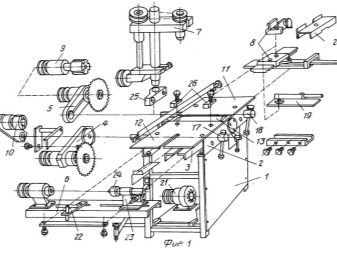

The equipment can be divided into several types. The machine can be a household machine with a thickness gauge, therefore it is suitable for a home, as well as an industrial one, it is larger and has a wider range of functions. Professional tools are often used in large enterprises, but a mini-machine has the same advantages, regardless of whether it is desktop, portable or combined.

Sawing units are designed to work with planks, bars and boards. This equipment has a simple design, the main role is played by a saw blade.With the help of planer-thicknessing machines, the surface of the material will become smooth and even. The equipment differs in a set of options, technical characteristics and purpose.

By versatility

This technique can be used for working with edges, it is suitable for sawing grooves, so that the technological processes are optimized. Some models offer a range of different attachments to enable milling, sawing and other types of processing.

It is safe to say that most of the machines are quite versatile, with their help you can make any products and elements from wood, the main thing is to have nozzles at hand.

By type and capacity of equipment

If we talk about highly specialized units, their capacity does not exceed 12 kW. They have high precision and excellent performance. Such equipment can be easily used around the clock, it can withstand heavy loads and show amazing results. The unit is suitable for working with large workpieces. Modern equipment is capable of performing complex operations, the process is controlled by electronics, which eliminates errors and defects in products. Automated workshops often use just such tools.

The engine power of universal models varies from 0.5 to 4 kW. As for the most powerful ones, they are connected to three-phase networks. Household tools are equipped with a motor of up to 2.5 kW, which is enough, as often in household workshops they work with small pieces of soft wood. These models are offered in a desktop version, which is convenient.

It should be noted combined machines that allow you to work with a part on the plane and from the side. On the market, you can find manufacturers that produce a device with a mechanical workpiece feed.

With the help of such a unit, you can process lumber in a carpentry workshop at home. The belt drive on the equipment protects the motor from overloading, which is especially important in cases where the tool is used for a long time.

Stationary stand-alone machines are quite expensive in contrast to portable ones, but they also have their advantages. The main advantage of the unit is the presence of a sturdy frame to withstand the load without the risk of damage, shock and vibration. The standard equipment of the professional equipment includes a protective device and a powerful electric motor.

The best manufacturers and models

To determine the choice of a multifunctional machine model, you should familiarize yourself with the rating of the best manufacturers of this equipment. The market offers a wide range of brands, many of which deserve special attention for a number of reasons.

Belarusian machine tools from BELMASH have gained great popularity, one cannot fail to note the well-known German company Bosch and many others. All devices are created according to the same scheme, the differences are only in some details, but each tool is durable, ensures accuracy, safety and productivity, which is equally important.

- Machine "CORVETTE 231-31" refers to a combined type, which is intended for planing, thicknessing, sawing and drilling. The cutterblock is equipped with cutting edges, so the surface is always clean. It is an inexpensive device that will last a long time, it is suitable for both the home workshop and the enterprise.

- Czech company PROMA offers the professional model ML353G for grooving, sawing, drilling and milling. The power of the unit is 4.5 kW. Thanks to three cutting edges, the equipment is easy to install and set up. As for the planing width, it reaches 600 mm, which is enough for working with furniture boards. For the price, it is a more expensive tool, while processing accuracy, as well as a rich set of functions, are guaranteed.

- If you are looking for something compact and convenient, you should pay attention to BELMASH SDM-2500PRO. The machine can cut across and along, as well as at an angle, it can be used to plan edges, milling and drilling. The motor power is 2.5 kW, the working shaft makes 2850 rpm. The planing width is 28 cm. This is a budget version of the tool that will serve for a long time and faithfully.

- "Master-wagon" is a combined woodworking machine that is used for sawing, milling, planing and drilling wood blanks. The tool has three functions, it can be used for planing at different angles, it is possible to install additional attachments that expand the capabilities of the unit.

- Desktop equipment STINKO WOODKRAFT ST-2200 has a power of 2.2 kW, the shaft has three knives, the diameter of the drill used can be up to 16 mm. It is one of the most budget-friendly tools for woodworking.

- Russian manufacturer "Kraton" also offers excellent equipment, in particular, the model WM-Multi-06P, which is capable of planing, drilling, milling. The motor power is the same as the previous version. This machine can work with boards up to 60 mm thick.

- The Hammer MFS900 can be attributed to the desktop. It is a compact device for sawing, polishing and sharpening cutting tools. It is safe to say that such a tool is great for a home workshop, the engine power is 0.9 kW. On the market there is a representative of the Japanese manufacturer Metabo HC 260 C for planing, thicknessing and drilling. Machine engine parameters - 2.8 kW, chip thickness - up to 3 mm.

Additional equipment

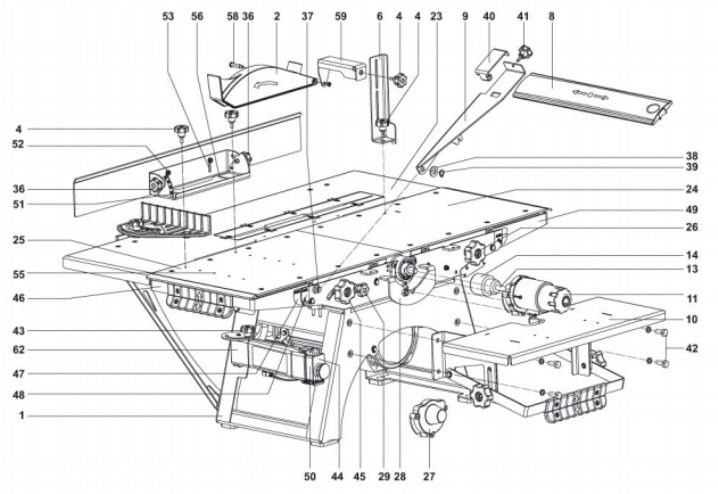

A great advantage of multifunctional machines is the ability to install different attachments to expand the options of the tool. The equipment allows you to carry out various operations with wood due to additional equipment in the form of a drill, milling cutter, circular saw, abrasive wheel, planer shaft, which is always indicated in the product description.

Each attachment has its own features and functions:

- a circular saw is designed for sawing;

- planing and planing is not complete without a shaft of knives, which are installed in the center of the surface;

- the knife shaft is intended for milling and drilling, the tool must be fixed with a universal chuck;

- the grinding wheel allows you to achieve a perfectly smooth flat surface, it is installed in the module.

Many modern machines can have such additional functions:

- smooth descent;

- vibration suppressor;

- magnetic switch;

- automatic feeding of blanks;

- emergency turn-off;

- protection against power surges.

Criterias of choice

It is not difficult to choose a machine if you decide on your personal requirements and take into account the place where it will be used.

For a home workshop, you do not need to take a professional tool, which is quite expensive, and besides, there are functions that are not needed. First of all, you need to pay attention to the speed indicator and motor power, it is he who directly affects the performance of the unit. High revolutions affect the quality of processing.

It is also important to understand the purpose for which the machine will be used, since 5000 rpm is enough for cutting, but at least 9000 is needed for planing. Some milling machines can carry out 20,000 rpm, this is professional equipment.

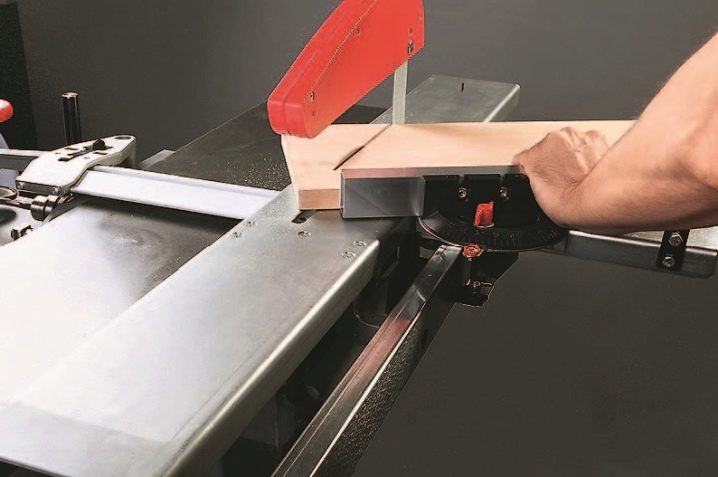

Convenience and accuracy of settings play an important role, as they directly affect a positive result. Of course, a beginner will need to learn how to use various stops, stands and other devices. Safety in such work is one of the factors that should be considered when choosing a machine. Such equipment is equipped with protective devices, please note if the tool has an emergency shutdown system, because different situations may occur during processing.

Possibilities

The woodworking machine has different abilities. The device allows:

- sawing across and along the workpiece;

- drill recesses;

- milling surfaces, choosing the desired configuration;

- planing the plane;

- make the edges of products.

At the same time, it is important to pay attention to the technical characteristics of the tool: is it universal or it has a limited set of functions.

Safety at work

Before starting a multifunctional machine into operation, it is important to study the set of operating rules and take safety measures so as not to harm yourself or others. There are hazards to consider during a woodworking operation.

- Parts of the mechanism and workpieces can move during operation, so they need to be fixed.

- Particles from abrasive materials can enter the eyes or the respiratory tract, this is important to prevent.

- Some machines are quite noisy and vibrate a lot. Experts recommend providing a comfortable working environment, checking the integrity of the insulation, as well as ventilation in the room.

- The working area must be well lit, there can be no foreign objects nearby.

- Make sure the flooring is dry and clean and check the electrical components before turning on. It is recommended to use a machine with a grounding circuit.

- Before starting, the reliability of fixation of all elements and the workpiece is checked, from time to time it is necessary to conduct a thorough inspection of the mechanism, the serviceability of the casings, etc.

- If necessary, use protective goggles, noise canceling headphones, protective clothing and shoes.

After completing all the preparatory work, you can start the woodworking process on a multifunctional machine.

The comment was sent successfully.