All about four-sided woodworking machines

For large-scale wood processing and furniture production, the availability of suitable equipment is required. Among the many pieces of equipment, it is worth noting the four-sided machines, which are an integral part of any professional wood procurement company.

Peculiarities

This type of machine has a number of features that distinguish it from other units. First of all, one of the advantages of the four-sided models is the versatility, thanks to which the user can perform many operations on the tree. Some of them can be carried out on other machines, but separately, while together they are performed only on this equipment. Indeed, there are many possibilities, because four-sided products are suitable for both planing and thicknessing. That is, the workpiece can be planed according to certain indicators of width and thickness. Previously, these two actions were done separately, but now everything can be done on one desktop.

In addition, these machines have the ability to milling. To do this, it is necessary to replace the cutting elements in the working heads from the planer shafts with cutters of a certain diameter. At the same time, the design of the products allows for both roughing and finishing. Four-sided machines are great because they can be used to work with a wide variety of workpieces. This feature is often used in situations where the final wood product often changes and does not flow. Changes can be made in the fastest way, without spending a lot of time on additional settings, because everything is already provided for by the design.

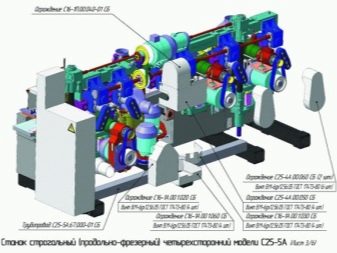

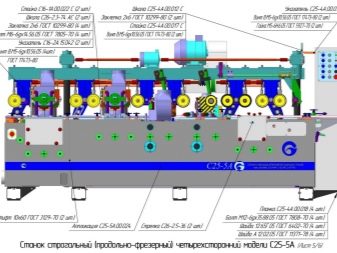

Four-sided processing is special in that it allows the production of many products: boards for lining and parquet, profiled or glued beams, skirting boards, lamellas, imitation of a bar, cashing and much more. Also, machines are actively used to create furniture of varying complexity. Structurally, the unit can have several working heads, which depends on the manufacturer and configuration.

It should be clarified that the maximum number of cutting tools reaches six, so the technique can perform several operations at the same time.

The device of the variator of four-sided woodworking machines allows you to change the gear ratio of the torque, thereby adjusting the speed of the product. A distinctive feature of such units is their design. It is based on a full-size bed. It can be either one-piece or with various inserts designed to increase the reliability and stability of the product (in the most vulnerable places). The bed is always made of cast iron, as it is very durable and, most importantly, absorbs vibrations well, thereby making the processing smoother and more accurate.

Also, do not forget about the desktop where the workpiece is located. Four-sided models have many options in order to modify this part of the structure, so it will be possible to personalize the operation for specific production needs. Of course, such equipment is not cheap, but its functions imply the operation of several machines at once, while this type of product is more convenient because it takes up less space and does not require a separate service over time. And maintaining the state of one piece of equipment is much easier than maintaining several. But in the event of a breakdown of the unit, the production capacity will drop dramatically.

Species overview

Longitudinal milling

This type of machine is used to cut a piece of wood to length. Due to the high quality of cutting tools, the equipment can perform profiling of the most varied complexity. The main work is carried out by the lower shaft by adjusting and specifying a certain thickness of the planed surface. The cutting tool moves vertically with the table top. It should be clarified that longitudinal milling machines can perform this operation in different ways, if the technical equipment allows it.

Thicknesser planers

With this method of work, a certain thickness of the part is set for the machine from several sides at the same time. Initially, it is a planer, and profiling acts as a separate function. The thicknessing and planing system allows you to process wood material from four sides at the same time, which significantly saves time.

The profile is simple and shallow.

Popular manufacturers

Beaver is a well-known company that manufactures its machines in China. The main advantage of the assortment is a wide model range, which is represented by a wide variety of products and even mini-machines. A special feature of the 4-sided Beaver units is that they optionally have 4, 5 or 6 spindles. Due to this, the buyer can choose a more suitable model depending on the production goals. Machines of this brand can be purchased in many stores or from other users, so they are very affordable. The price is also attractive, which does not exceed similar indicators of its competitors.

Overall, Beaver's four-sided woodworking machines are among the best in terms of value for money. Quite good technical indicators, inexpensive repairs and ease of operation make the models quite popular at various enterprises in Russia. The products of the Chinese manufacturer are used in many areas, among which the main ones are the creation of furniture and the procurement of building materials.

V-Hold is a domestic manufacturer that began its distribution on the Russian market since 2002. The advantage of the company is that it not only designs machine tools, but also helps its customers in starting up their own factories. V-Hold personally works with the customer in order to create a technique depending on the requirements and goals of the buyer. The main emphasis is on the versatility and ease of use of the equipment. The price range is average, all products have certificates of conformity to European quality.

The machines of this company are popular both in Russia and the CIS countries and abroad.

DMG MORI is one of the world's largest brands (Germany and Japan). The distinctive features of the entire product line of this holding are premium quality and the active use of various technologies, which are both standard and innovative in their field. Four-sided woodworking machines from DMG MORI are part of the production facilities of many large industrial enterprises, where a constant mass production of workpieces and materials is established.

When choosing equipment, the manufacturer gives the user complete freedom and allows him to set certain parameters that would suit him. You can choose processing technologies, individual segments and methods of operation, as well as all kinds of control systems supported by the technology. The main emphasis in the assortment is placed on CNC units and software, due to which the equipment achieves high accuracy and quality of work.

GRIGGIO is a popular company from Italywhich creates high-tech 4-sided models based on many systems and functions. Among the most important advantages are the versatility of the machines, as well as their reliability. Naturally, the price cannot be called low. The company is actively modifying the production of products, thereby gradually increasing the overall level of the model range. The company has extensive European experience in machine tool construction, so it knows the needs of customers very well. It was this knowledge that allowed GRIGGIO to become popular in many countries.

Components

Four-sided woodworking machines are very diverse and can be improved through the use of accessories. A very useful purchase is the cross-type automatic feeder, if this function is not initially available in the machine's configuration. This part of the structure is great for machines that are used for planing decking and other long workpieces.

Increasing the feed rate of the material increases the degree of automation and intensity of work, and therefore the unit processes more wood in one shift.

Among other components, it is customary to highlight cutting tools that play an important role in the workflow. Scoring and frame cutters, saw blades of different diameters, edges and other structural elements make operation more flexible and versatile. It is these components that are perfectly combined with four-sided machines, the capabilities of which are very wide in comparison with other similar equipment. After a certain time of use, it becomes necessary to change individual components, among which spindle bearings and feed rollers can be distinguished.

When choosing the latter, it is important that they are made of durable, reliable material with a polyurethane coating, because it is this material that does not spoil the appearance of the workpiece and does not leave any traces on it. There are quite a few modifications for the desktop as well. Some manufacturers allow the buyer to optionally choose the lengthening of the structure in order to accommodate larger workpieces. Also, the work table can be equipped with a side clamp to increase the reliability of fixation and millimeter-pitch rulers, which allows the user to more accurately guide the wood to the cutting tool and stop the machine at the right moment.

Nuances of choice

With a large number of machine tool manufacturers and all their variety, the consumer may have difficulties as to how to choose the right unit. This will help certain criteria, under which the buyer can find a good model. To begin with, you should pay attention to the materials for the manufacture of the structure. The base frame is the part of the machine where it is most important to use the right raw material. Cast iron is an excellent option due to its many benefits. It is not only strength and heavy weight, but also resistance to physical damage and vibration that occur during operation.

An equally important element of the four-sided machine is the working table. Well-known manufacturers are very versatile in their approach to its configuration, and therefore supply it with various mechanisms, due to which it is possible to process a workpiece of a non-standard size. It is desirable that the work table be equipped with rulers or pointers, as they improve the user's perception of the systems for measuring and guiding the wood towards the cutting tools.

When buying, pay attention to the dimensions of the surface.

A big plus is the presence of an automatic material feeding system. When choosing a unit, compare the models by the speed of this component, because it directly affects the working volume of the machine. If your budget is affordable, try to purchase a model with CNC, as this system greatly simplifies the process of setting up the equipment. It will only be necessary to program all the stages of work, after which the user's participation will be minimal. In this state, the product has a high degree of automation, which is accompanied by high precision and quality of processing.

Remember to read reviews and information regarding product features and specifications before purchasing equipment. Remember that the accuracy of the machine depends on the quality of materials and assembly of the machine, which is one of the most important indicators for units.

Exploitation

An equally interesting aspect of using the machine is its direct operation. It includes not only how to properly set up the unit, but also the safest way to organize the workflow. With electronic systems, you just need to learn how to use the mechanisms and use them to process wood. If contact with the equipment is required, it is important that the user has a complete set of protective clothing.

A lot of problems with machine tools arise due to malfunctions in the power supply system. Therefore, before starting each operation, check the communications for their operability. Keep the cleanliness and order near the equipment, in case of breakdowns, trust the professionals who have experience in repairing such equipment.

The comment was sent successfully.