All about slabs

The concept of "slab" can be heard from master cabinetmakers and manufacturers of stone products, but ordinary people often want to figure out what it is, where it is used. In fact, by this name, experts mean large-format blanks with an untreated edge, obtained by sawing an array of material. Slabs made of porcelain stoneware, gabbro, marble, onyx and other raw materials are used for the manufacture of window sills and other products, their main values are in the uniqueness of the pattern, as well as in the integral structure of the product.

What it is?

Initially, the concept of "slab" came from geology, where they denoted layers of natural stone or rock, resulting from the cutting of the massif. Later the same term was used by master cabinetmakers working with expensive or exotic plant species. If the board is always obtained by cutting the log to length, the slab can be created by radial or oblique sawing. The dimensions of each of these elements are individual, depending on the dimensions of the feedstock.

Wooden slabs usually have the following features.

- Unique surface pattern... Each knot, crack or defect in the trunk can turn into the main focus of the future product.

- Standard thicknesses in 30-200 mm... The most popular slab size is considered to be 60 mm. Width - 0.5-0.9 m, less often - up to 2 m.

- No signs of sticking or splicing. This is the main value of solid cuts.

- Natural edge cut. It additionally gives uniqueness to the product.

Since slabs are most often used in the manufacture of countertops, the edge that has preserved the bark becomes one of the main accents in the product.

Stone slabs - monolithic slabs with a thickness of 20-40 mm, cut them out primarily for ease of transportation... In the form of such plates, they are transported from mining sites around the world. The standard dimensions of stone slabs do not exceed 2 × 3 m. They can be made to order in any size range.

Features of production

The production of stone slabs is carried out in quarries, in the places of their extraction. Huge chunks of slate, tuff, marble or travertine are chipped off the solid and then sawn to fit the material in a transport vehicle. The correct choice of mining method helps to preserve the structure of the stone. Typically, a directional explosion or an air cushion is used for this.

Sawing is performed with disc machines to make the processing more accurate. Then, if necessary, make alignment, milling, grinding, polishing. Marble and granite blocks are cut with diamond tools. The required thickness for cutting is selected immediately. Then the slabs are sent to a warehouse or workshop.

Harvesting wooden slabs also has its own characteristics. Forest felling can also be done with a chainsaw.

This job does not require high precision or clean cut. But to make separate plates of the desired thickness from the trunks, a band or chain saw will help; post-processing will require a specialized machine.

Views

The very concept of "slab" today is equally often applied to both stone and solid wood slabs. The most commonly used materials for the manufacture of such solid plates are the following materials.

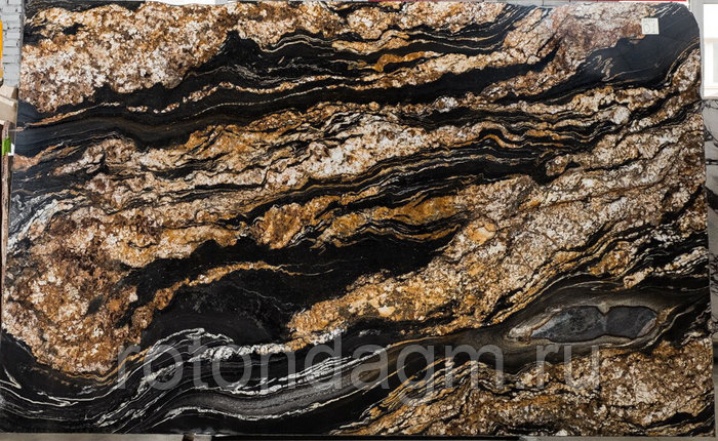

- Marble massif. One of the most popular slab options.Slabs of rare beauty in black, yellow, white, blue, green, red, gray colors are made of marble - there can be many options for shades. Plates are quite easily processed, polished and polished, when impregnated they acquire increased moisture resistance.

- Onyx... Unique stone: translucent, translucent. Has unusual color transitions, spectacular unique patterns on the surface. All these advantages are somewhat limited by the range of plate thicknesses - up to 15 mm.

- Granite... A rock that is practically unmatched in hardness. Slabs made of it are very durable, and the color range is as diverse as possible, depending on the deposit and composition. Not all types of granite are suitable for indoor use; it is important to pay attention to the safety class of the material.

- Gabbro... A stone of magmatic origin, a rock with a complex composition and structure. Outwardly, it may look like granite, it has a wide variety of colors.

- Agate... Mineral related to quartz. Its main advantage is an unusual striped structure, which looks especially impressive on a slab.

- Quartzite... A very dense rock, difficult to work with. It has a beautiful cut structure, it can be white, red or gray. The composition is dominated by quartz particles.

- Slate... Inexpensive, but quite respectable and externally noble stone, especially appreciated in the variant of processing with natural chips. The main shades are from black-graphite to burgundy, there are multicolor pattern options.

- Labradorite... After polishing, the slabs obtained from this rock acquire a special iridescent structure, combining different shades of yellow, green and blue.

- Oak... Sturdy wood with a noble grain weave pattern. It lends itself well to processing: brushing, toning, soaking with oil.

- Ash... Wood species with a very light shade of solid, almost white, pleasant to the touch. Finding a large-format slab is considered a great success.

- Pine. Light, light straw wood and characteristic resin aroma - this material retains its main features even in slabs. But in terms of hardness, wear resistance, it is much inferior to other breeds.

- Larch... It is characterized by a special greenish tint of wood. The cut is very beautiful.

- Nut... One of the most beautiful wood options, it has a luxurious pattern on the cut. This material is expensive, but has a rather dense structure. Products made from it are durable, effective, reliable.

- Maple... The wood of this plant has an unusual reddish tint. Small elements are often made from maple, since the trunk diameter rarely reaches significant sizes.

- Elm... Wood species with a unique pattern on the cut. Gives the products special attractiveness and durability.

- Suar or tamarind. An exotic “guest” is a rain tree from the jungle of Indonesia and other Asian countries. Its giant trunks are cut radially, obtaining cuts that are unique in the beauty of the pattern.

- Poplar... Material with a luxurious texture. You can create real masterpieces from poplar due to complex color transitions and different directions of wood fibers.

- Birch... An affordable option for a summer residence or a country house.

A slab of solid birch is prone to cracking, therefore it is rarely used for the manufacture of furniture or furnishings.

Instead of natural stone, its artificial counterpart can be used for the manufacture of various products. Most often it is porcelain stoneware or slabs based on quartz agglomerate. They are immediately manufactured in the right size, have impressive physical and mechanical properties, and allow you to select a color scheme at the request of the customer. Slabs made of exotic wood are often combined with epoxy resin, creating compositions of unique beauty with a translucent central part.

Where is it used?

Slab products are also quite diverse. From stone and wood cuts can be made:

- window sills;

- bar counters;

- headboards;

- benches;

- doors;

- steps;

- racks;

- whatnots, cabinets and other pieces of furniture;

- fireplace shelves.

Elements of fences and gates can be made from inexpensive slabs. Small-diameter slabs can replace tiles or be used as clock bases, shelves in the bathroom under the sink, mirrors. Stone elements of small thickness can be mounted on the wall as a decor in the interior, to make unique panels or mosaics from them.

In the design of summer cottages and country houses, tabletops for gazebos, fireplace rooms, dining areas are made from wooden saw cuts. The larger the size of the product and the more exotic the pattern, the better.

The comment was sent successfully.