Silicone plaster: types and advantages

In the modern market of finishing materials, there are many different compositions for finishing. One of the highest quality finishing materials is silicone-based plaster. Due to its unique composition, such a mixture has excellent technical characteristics. Such material is practical to use; it not only evens out the walls, but also creates a decorative coating. This article discusses in detail the types and advantages of the composition.

Material features

Silicone plaster is a type of polymer mixture. Silicone based mortar is used for finishing walls indoors and outdoors. This mixture is considered one of the best among other finishing materials. Due to its special composition, silicone plaster has many unique qualities that other plaster mixes do not have.

Silicone mixture has high technical characteristicswhich ensure a long service life of this coating. Such material is resistant to various adverse influences, which makes it possible to use it for facades in regions with any climate.

The silicone-based coating is available in a ready-to-repair form. You do not have to spend time and effort preparing a solution for application from a free-flowing mixture. Working with silicone plaster is quite easy - thanks to the consistency of the mortar, easy to apply, as well as good adhesion. After application of the mixture, a strong and elastic coating is formed on the surface, which is resistant to cracking.

The silicone compound is easy to apply to most types of materials.

Most often, such a solution is used for cladding the following surfaces:

- drywall sheets;

- gas silicate blocks;

- wood;

- cellular concrete.

Advantages and disadvantages

The silicone mixture contains silicone resins, which give the material unique technical characteristics.

The advantages of such material include:

- Significant service life. Manufacturers claim that such a coating will last at least twenty years (even under the most unfavorable external conditions). Under favorable operating conditions, the service life of the coating can be up to thirty years.

- Creates a coating that is not susceptible to the formation and spread of mold and mildew.

- High level of vapor permeability.

- Good ductility.

- Antistatic properties. The top layer of the coating is antistatic, due to which dust and other contaminants are not attracted to the surface. This property allows you to use the material for finishing buildings that are located next to the roadway.

- The coating is resistant to alkalis and acids.

- High strength.

- High level of adhesion.

- Does not fade when exposed to direct sunlight.

- Has thermal insulation properties.

- Moisture resistance.

Silicone plaster has not only advantages, but also certain disadvantages.

The disadvantages of this material include:

- high price;

- the complexity of dismantling.

What are they?

Silicone plasters can vary in composition and texture.

The material is also divided into some groups (depending on the field of application):

- For interior renovation work.With the help of such a material, you can create quite interesting textured coatings that are distinguished by an attractive design.

- For outdoor renovations. This coating has a high level of resistance to weathering.

- Universal application. Most often, such mixtures are made on a silicate-silicone base. This composition has good frost resistance and can be used for additional wall insulation.

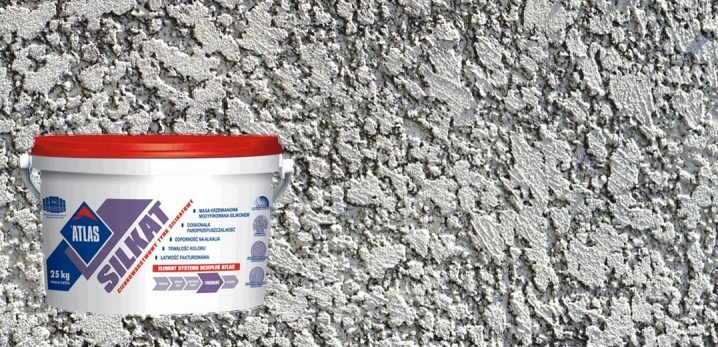

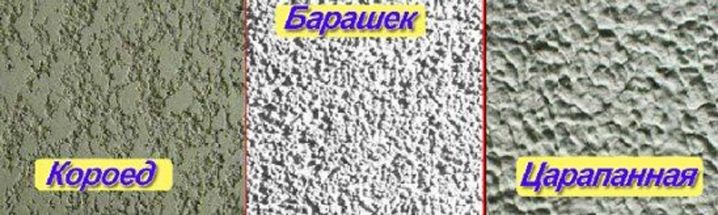

By structure, there are two main types of material: "bark beetle" and pebble plaster (or "lamb"). The mixture "bark beetle" forms a coating that visually resembles a surface eaten by beetles. Pebble plaster forms a grainy, rough surface.

Selection recommendations

There is a wide range of silicone plasters on the market of finishing materials, which differ in certain parameters.

When choosing the right mixture, you need to pay attention to the following factors:

- Expiration date of the material. In order for the purchased mixture to meet all the declared characteristics, it must not be expired.

- Grain. The texture of the coating will depend on the size of the grains in the mixture.

- Colour. If it was not possible to choose a mixture of a suitable color, then you can additionally purchase paint for plaster.

- Type of finishing works. Facade plaster should be more frost-resistant.

- Material consumption.

- Operating temperatures.

- Temperature at which finishing work can be carried out.

- Drying time.

Application technology

Before starting finishing work, the walls must be cleaned of dirt that can interfere with the good adhesion of the material to the surface. Serious defects in the form of deep cracks and chips must be repaired with putty. A layer of cement-based plaster can be applied to level the walls.

It is recommended to prime the cleaned surface. It is better to use silicone-based formulations as primers. Stir the plaster well before applying to the surface. If the solution is too thick, then it can be slightly diluted with water.

To apply the mixture manually, you will need the following tools:

- plastering trowel;

- long spatula;

- trowel for plaster.

It should be noted that this material can be applied not only by hand - the use of a plaster station is allowed. When purchasing a material, you should check whether the product is suitable for machine application.

The applied layer of facing material should not exceed the size of the mortar grains. The number of layers itself is not limited. The application technique and further work on the formation of the decorative coating depend on the effect you want to get. Various stencils can be used to change the structure of the coating.

Popular manufacturers and reviews

Before purchasing a silicone mixture, it is worth learning as much as possible about the manufacturers of such materials and familiarizing yourself with reviews of their products. Since this plaster is quite expensive, there are fakes on the building materials market. It is worth purchasing products from only trusted manufacturers. Whenever possible, it is best to ask stores to demonstrate the appropriate quality certificates.

Henkel

The German company Henkel is known all over the world as a manufacturer of quality products in three different categories at once. This company produces cleaning products, beauty products and building materials. Mixes for repair and construction work are produced under the Ceresit brand.

Ceresit silicone materials are designed for the creation of thin-layer coatings on interior or exterior walls. Small cracks on the surface can be bridged with this material. Ceresit silicone plaster is available as a base for tinting. The service life of this coating declared by the manufacturer is at least ten years.

The Henkel plaster does not contain toxic substances, so the material is absolutely safe for human health. The mixture has a slight odor that is easily eroded from the room. The operating temperature range is -50 to +70 degrees Celsius.

Most often, there are positive reviews about Ceresit silicone plaster.

Buyers note the following features of the decorative coating:

- ease of application;

- long service life;

- does not fade when exposed to sunlight;

- great quality.

Among the disadvantages of this material, its high cost is noted. Not every consumer can afford such a plaster.

"Kreisel"

The Kreisel company is engaged not only in the production of building materials, but also in the independent extraction of raw materials for its products. Initially, the company specialized in the manufacture of cement mixtures, but gradually the range of products has expanded.

Kreisel silicone plaster is divided into two types:

- decorative mixture for indoor and outdoor use;

- silicate-silicone material.

These materials are suitable for both manual and machine application. The grain size in a mixture of decorative plaster can be one and a half or two millimeters. This solution is available in a wide range of colors. The total number of shades is four hundred and six different options. The drying time of the mixture depends on various factors, it can be from twelve to forty-eight hours.

Kreisel silicone-based plaster has won many positive reviews.

Consumers highlight the following advantages of this product:

- high quality;

- good indicators of frost resistance;

- ease of use;

- high level of vapor permeability;

- high strength.

Weber

Weber is a leader in the production and sale of dry mixes for repair and construction work. This company has an extensive network of manufacturing plants and operates in fifty-nine countries.

Weber's silicone decorative mixture is called Weber. pas silikon. This material is intended for external and internal construction work. This plaster can be applied not only to walls but also to ceilings.

Apply Weber material. pas silikon is possible even in bad weather conditions. The mixture is produced in white (for further tinting).

Buyers highlight the following advantages of such coverage:

- high level of adhesion;

- good quality;

- crack resistance.

The main drawback of the Weber materials. pas silikon is high cost. Many similar formulations have this disadvantage.

For the characteristics of silicone plaster, see the following video.

The comment was sent successfully.