Facade decorative plaster: varieties and properties

The external attractiveness of a home is a very important aspect for a country house, but do not forget about the protective properties of the external facade finish. A popular method - decorative plastering has a number of features that must be taken into account when decorating the exterior of your estate.

Features and characteristics

A large private home needs a beautiful, affordable, sustainable and protective design. Decorative facade plaster meets these requirements. This coating can be applied without special application skills, you just need to adhere to the technology.

There are a number of features for finishing the facade with decorative plaster:

- thanks to UV protection, the paint does not fade longer and retains an attractive appearance;

- the material is resistant to temperature extremes, is not afraid of severe frosts, perfectly tolerates a humid and hot climate;

- facade plaster does not deteriorate and does not change its properties from rain, snow, wind;

- finishing material has good ventilation properties, allows the whole house to "breathe";

- does not have harmful impurities, so the plaster is safe for human health;

- the solution can be applied to any wall material - concrete, stone, cement, drywall or over other plaster;

- plastered walls can be easily repainted in various colors, combine shades, combine them with each other;

- changing the method of application, you can achieve different texture and relief.

It is also worth noting that such material is repairable. In case of chipping, cracking, the defect can be eliminated directly at the place of its appearance, which, for example, is impossible in the case of facing the facade with siding. You just need to apply a fresh layer of plaster in the place of its deterioration.

Types and properties

There are different types of facade plaster. Depending on the raw material, this material has different properties that must be taken into account when choosing a particular product. Before proceeding with the cladding of the facade, you should study the basic criteria.

Mineral

Mineral plaster is notable for its low cost, it is produced in bags. The predominant substance is cement.

This material has undeniable advantages:

- Mineral plaster perfectly "breathes" and is capable of letting in steam and moisture, which have a detrimental effect on load-bearing structures and partitions.

- The material does not allow fungus and mold to multiply.

- Does not burn or ignite.

- Choosing mineral plaster, you can be sure that it will not crack or shrink after drying.

- The material has a high degree of frost resistance and moisture resistance.

- Facade finishing can be done at any temperature.

- No additional care is required.

- There is no harmful effect on human health.

There are also disadvantages that are important to consider:

- The substance is available in dry bags. Before starting work, it is necessary to dilute the mixture. The suitability of the material will depend on how the proportions have been observed.

- It is not always possible to carry out the facing work on your own. This requires a certain skill and experience.

- Not all colors and not all paints are suitable for tinting. The material itself is dark and difficult to paint over.It is necessary to paint in several layers, which increases costs.

- The material does not tolerate vibrational vibrations.

- Differs in a short service life. Guaranteed - 10 years.

Silicone

A special silicone resin is added to the composition of such a plaster, which has a high degree of elasticity. Manufacturers offer to buy a ready-made mixture that does not need to be diluted.

In addition, there are a number of advantages:

- The elasticity of the material makes it possible to fill the cracks that occur during the planting of the building.

- Does not allow fungi and mold to multiply.

- Perfectly repels moisture, does not allow it to penetrate inside.

- However, it passes steam perfectly.

- Resistant to low and high temperatures.

- There are two methods of application: manual and mechanical.

- Perfectly interacts with the surface to be applied.

- There is no unpleasant odor.

- It is a durable finishing material. The guaranteed service life is 25 years.

The only significant disadvantage of silicone plaster is its high cost.

Silicate

The silicate mixture is based on liquid glass. Such plaster should be used outside buildings that are insulated with mineral wool slabs or expanded polystyrene, it is suitable for floors made of aerated concrete or gas silicate blocks. Sold ready-made.

Material advantages:

- This material is not electrostatic.

- It has an average level of elasticity, but it fills well cracks from shrinkage.

- The degree of vapor permeability is high.

- Has particles that are capable of repelling water.

- Can be diluted with water.

- It is considered a durable facing material - up to 20 years.

However, silicate plaster is quite capricious:

- Opened can dries quickly.

- Before applying the composition, it is necessary to prepare the base - to prime the surface. Additional manipulations increase the time to complete the work.

- Requires certain skills and experience from the employee.

- It is not permissible to apply the finishing material at low temperatures, optimal weather conditions are 20 degrees above zero and humidity 60%.

- Shelf life is only 1-1.5 years with the integrity of the package.

Acrylic composition

The mixture is based on acrylic resin. The material is sold ready-made, it is not required to breed. Advantages:

- Thanks to the acrylic polymer, the plaster, as it dries, becomes very durable, not afraid of mechanical stress.

- Has high UV protection.

- Does not allow moisture to pass through from rain and melting snow.

- Does not provoke fire and, in principle, does not burn.

- It quickly cures and hardens, which allows you to quickly achieve results or proceed to applying a second coat or paint.

- Not afraid of strong changes in temperature and humidity.

- It can work at any temperature.

- Plaster is an elastic material that penetrates into shrinkage gaps, as well as into the pores of the base. This characteristic allows the decorative material to obtain good adhesion to the surface on which it is applied.

- Almost any paint can be applied to hardened acrylic mixtures, any color can be achieved.

One of the disadvantages of this decorative finishing material is a high degree of electrostaticity. This disadvantage leads to the fact that the walls attract dust and dirt.

In addition to utilitarian properties, plasters have different decorative characteristics. There are different textures that can be achieved either by choosing specific blends or by applying the material.

Mosaic

This building material is a mixture of acrylic resin and natural stone chips. This type of finishing material is widely used: it can be used both to create the interior and exterior of the house. Different types of mosaic plaster are used for the exterior walls and basement of the building.

The crumb can be based on natural stones: granite, marble, quartz, lapis lazuli, malachite.The size of one granule ranges from 0.8 to 3 mm. After the mixture dries, an interesting to the touch surface with a special structure is formed.

Mosaic mix has a classification, it is divided into the following types:

- coarse-grained: coarse crumbs with a diameter of 1.5 to 3 mm are mixed into the mixture;

- mixtures with medium or small fractions: from 0.9 to 1.5 mm;

- fine texture mixtures with a granule size of less than 0.9 mm.

There is also a classification according to the type of stone used, for example, marble or malachite mosaic plaster mix.

The process of applying the material is not considered easy, it requires certain qualifications from the master. It is undesirable to get down to business on your own if you did not have the appropriate experience. To avoid wasting expensive material, it is better to hire a specialist.

Structure and colors

Thanks to the possibility of creating a textured surface, a number of important issues are solved:

- Due to the uneven texture, small cracks become invisible, moreover, such a surface tolerates stress better than a smooth one;

- Based on decorative purposes, you can pick up reliefs that are different in appearance and touch.

There are three most common types of structures:

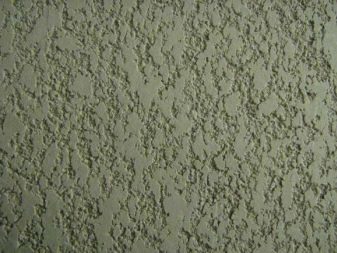

- "Bark beetle";

- "Lamb";

- "fur coat".

The first type got its name due to the fact that after applying to the prepared walls and drying the mixture, the effect is formed as if the surface eaten by a bark beetle. This is achieved due to the fact that the composition of the material contains special fractions with a diameter of 1.5-2 mm, which at the time of grouting form characteristic grooves.

This type of mixture has a finishing purpose and was created for external finishing work, but due to its excellent utilitarian qualities, it is often used for cladding the internal walls of industrial premises.

The layer of "bark beetle" application is small, only 1.5-2 mm, but do not forget that this coating is decorative, therefore it is applied to an already prepared surface.

The lamb structure is formed by small rounded stones of dolomite, marble and quartz. Such a decorative material is applied with a special construction trowel or roller, which allows you to distribute the mixture evenly.

The surface of the walls, on which the plaster "fur coat" is applied, has a pleasant roughness and graininess. It contains dolomite chips up to 3 mm in size. It is important that the applied layer does not exceed the thickness of the grain size. The required structure is also achieved with a roller or trowel moistened with water.

Sometimes mica is added to the composition. Such a mixture of sparkles shimmers in bright sunlight, greatly enlivening the composition.

For painting the facade of the building, you can choose absolutely any color. Often two or three colors are combined to accentuate architectural elements such as pilasters, columns or plinths.

Finishing work

Building a house is a complex, long process, costly in terms of resources and forces, therefore it is important to pay attention not only to the quality of the material, but also to the technology of its competent use. Decorative street plaster is, first of all, a material from which decent external characteristics are required, it is a finishing material. Therefore, it should be applied already on a prepared base.

Requirements for the base:

- The surface should be cleaned from dirt, dust to achieve better adhesion.

- If there is wallpaper or old plaster on the wall, they should be removed.

- The prepared surface must be dry, free from crumbling and detachment of the material.

- Before applying the topcoat, it is necessary to provide the base with an even surface without strong dents and cracks. A thin decorative layer will not be able to hide them.

If the walls do not meet the above requirements, they should be repaired:

- if cracks are found on the base, they are filled with a sand-cement mixture using a spatula;

- the outer walls of a brick house are filled with leveling, plastered, primed;

- it is important to wait until the walls are completely dry.

For applying textured decorative coatings, namely, to achieve the desired effect a number of technological features should be taken into account:

- Dilute the mixture by pouring out the entire package. This rule must be observed in order to avoid the settling of fractions at the bottom of the bag.

- The mixture is diluted with water, mixed with a construction mixer, kept for 5 minutes so that the particles absorb water, then stirred again.

- Working with the "bark beetle", you can get the necessary furrows only after the topcoat layer has dried a little (10-15 minutes after application).

- After that, a plastic float should be pulled from top to bottom so that the dolomite chips begin to pull behind it. If you do not wait, the whole mixture will creep down.

- The "bark beetle" should be worked "from corner to corner" so that the mixture does not have time to dry out completely.

- It's easier to work with a "fur coat". The texture is formed immediately on a wet layer using a float or roller.

- All finishing work should be completed within 3 hours, otherwise, due to the drying out of water, the material begins to lose its elastic properties and may not adhere well to the base.

Manufacturers

There are many firms and companies engaged in the production of outdoor decorative plaster. In different products, the composition is slightly different, which can lead to a different degree of elasticity of the material, as well as a change in its basic properties. The effect of "bark beetle", "lamb" or "fur coat" for manufacturers can also vary, since each company uses dolomite chips of different diameters.

The most famous domestic and foreign manufacturers:

- "Prospectors";

- Grafics;

- Isomat;

- Krafor.

Beautiful exterior options

"Bark beetle" on the facade is perfectly combined with other finishing materials such as wood, natural or decorative stone. The main thing is to find the optimal balance of color and texture features. It is also worth paying attention to the fact that it is not necessary to create furrows parallel to each other. An ornate and creative pattern looks unusual and original.

"Fur coat" is a great option for those who love a more delicate texture. Thanks to the method of application, beautiful streaks and color transitions are formed on the surface, reminiscent of Venetian plaster.

Mosaic plaster with marble fractions looks noble and at the same time elegant. Choosing stones of a different material, you can play with color and tints in the sun.

With the help of this video, we learn how to apply facade decorative plaster.

The comment was sent successfully.