Warm plasters for interior work: features of choice

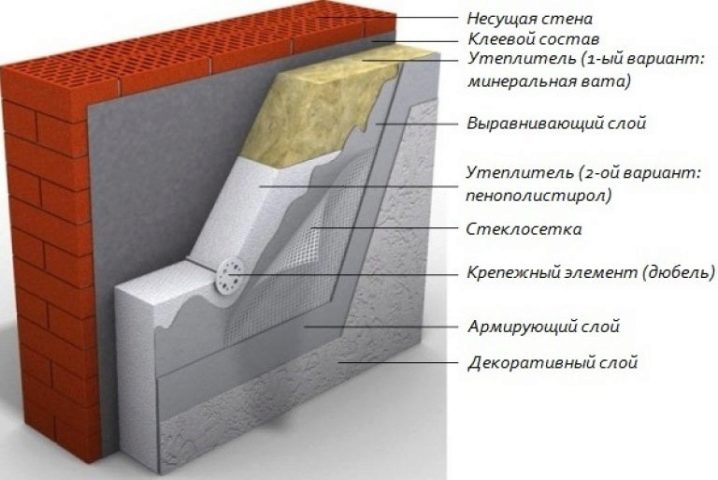

The warmth in the house is one of the most important factors to look out for when building a building. There are various ways to minimize heat loss. Today, special warm plasters are increasingly used for this. They are applied only from the inside, which allows you to additionally level the walls for further decoration.

Peculiarities

Warm plaster is a cement-based mixture, the main task of which is to keep warm inside the room. Classic sand-based solutions are characterized by high heat loss. To increase thermal insulation, various fillers are added to the plasters that can create a porous structure.

Today, in production, these products are made from the following substances:

- expanded clay;

- perlite;

- sawdust;

- expanded polystyrene.

Plasters of this type have several positive features:

- Ease of application. The technology of wall covering practically does not differ from the classical plastering with cement mixtures.

- Versatility. With the help of plaster, not only heat loss is reduced, but also the walls are leveled for decorative finishing.

- Water vapor permeability. Substances pass moisture well, which allows you to create an optimal microclimate inside the house.

- Lack of cold bridges.

- Good adhesion to various types of surfaces. This allows you to finish almost all walls with minimal cost and effort. On some substrates, plaster can be applied even without priming.

- Decent soundproofing. The compositions absorb sound waves of various ranges well. But if they are affected by vibration, then they are not able to hide such noise.

- Plasters are not damaged by rodents, and mold and other harmful microorganisms do not develop in them.

Warm compositions are not versatile, as they have several significant disadvantages:

- High price. It is quite expensive to purchase such compositions in large quantities, which makes people look for alternative insulation options.

- Low coefficient of thermal conductivity. This indicator for plasters is much inferior to that of such heaters as mineral wool, expanded polystyrene or polyurethane foam.

- The maximum thickness of the plaster cannot exceed 5 cm. If this value is increased, then the composition, after hardening, will begin to peel off very quickly.

- Relatively high density. Although the composition includes relatively light materials, after being applied to walls, they can create a significant load on the surface.

- Almost all types of plaster mixes should be coated with additional protective solutions after application. In most cases, puttying with various compounds (based on gypsum or cement) is used for this.

Views

Modern manufacturers present many types of warm plasters. Depending on the composition and the presence of the main component, the following types of mixtures can be distinguished:

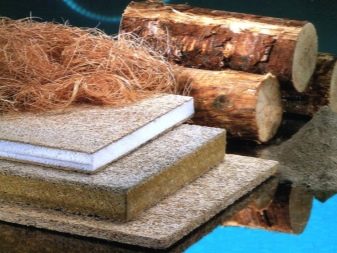

- Expanded rocks. The most common type of heat-saving plasters. They are obtained in the process of high-temperature processing of various types of mineral fillers. Today, expanded clay chips, vermiculite and perlite are increasingly used for this. Such products can be used both inside and outside buildings.But the latter option requires additional processing (reinforcement, decoration), since water will penetrate the rooms through the pores, disrupting the structure of the finishing materials.

- Expanded polystyrene compounds. Plasters on a similar basis also receive unique protective properties. But experts recommend using them only for external walls. This is due to the fact that the material is not environmentally friendly, therefore it is undesirable inside residential premises.

- Foam glass based plaster. The filler is obtained from glass waste or directly from quartz sand. All these components melt and lend themselves to successive foaming, which allows achieving unique technical parameters. Foam glass-based plaster mixes are lightweight and have good heat retention rates.

This material is environmentally friendly and safe, since it does not emit any harmful substances at all (even when heated). Therefore, such a substance is one of the leaders in the manufacture of heat-saving plasters.

- Wood sawdust. The material is often used in industrial production. It is also used by many craftsmen for the preparation of warm plasters. Compositions based on sawdust have unique heat-saving characteristics, and are also completely safe for human health. But with strong heating, sawdust can begin to smolder.

It should be noted that warm plasters are not a universal insulation, since they are not capable of replacing classic materials. But if you need to improve the thermal insulation properties of wall surfaces, then it will be the best solution.

Application area

Warm plasters are the name of a class of mixtures that can increase the thermal insulation of a surface. This has led to such a widespread distribution of this product in the modern market.

Similar compositions are used to solve several problems:

- Alignment and insulation of facades. In theory, various thermal insulation plasters can be applied outside the building. But some of them can withstand changes in temperature and humidity, while others should be additionally covered with a protective layer. Therefore, the use of such materials outside is limited to only a few varieties.

- Alignment and thermal insulation of interior walls. Almost all types of plasters are suitable for such purposes. Some of them are able to change not only the heat-insulating properties, but also give a decorative effect.

- Insulation of structures that were built on the principle of "well masonry". Insulating plaster is used here to fill the voids that have formed in the structure of the wall.

- Protection of the sewer or water supply system from the effects of low temperatures. In most cases, they are used in places where pipes are adjacent to the house. This type of work requires preliminary planning and the creation of protective cages.

- Insulation of door or window slopes. Insulating plaster prevents cold bridges. This avoids condensation.

- Thermal insulation of ceiling or floor surfaces. But such use of them is relatively rare, since users prefer classic insulation and approaches.

Application technology

Warm plasters are practically indistinguishable from classic mixes.

The plastering process can be broken down into several sequential steps:

- Surface preparation. This type of plaster should only be applied to clean and even walls. It is desirable that they be free of cracks and other physical damage. Therefore, first of all, it is necessary to eliminate the cracks with cement mortars.

- Padding. This operation is optional for many mixtures. It is advisable to clarify this fact before using the solutions.But experts recommend almost always covering the walls with deep penetration primers. They will not only strengthen the wall, but also remove dust from its surface.

- Preparation of the solution. All components should only be mixed in precise proportions. Experts recommend kneading the entire package at once, since the components in it can be unevenly distributed.

Mixing of masonry mortar is carried out with a construction mixer. Please note that this should not be done at high speeds. It is advisable to add the dry mixture to the water, and not vice versa. Thus, a uniform and high-quality plaster can be obtained. To check if the mixture is ready, you need to draw it on a spatula and turn it over. In this position, it should not fall.

- Installation of beacons. These elements are located along the entire perimeter of the walls. They allow you to achieve a perfectly flat surface.

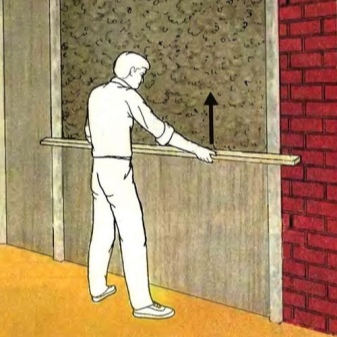

- Plastering. The composition is applied with a wide spatula between the beacons. Experts recommend starting work from the bottom and moving up. The solution is spread in an even layer. When the area between adjacent beacons is full, you can start leveling. To do this, using a long rule, the mixture is shifted, while resting on the supports.

- When the plaster hardens a little, you need to take out the beacons and fill these places with a liquid composition. At the very end, the final alignment is carried out.

Manufacturers

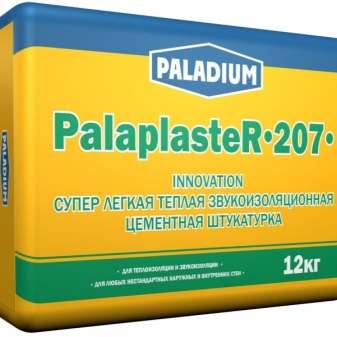

Warm plasters differ in composition, which affects their physical properties. Today, many cement mortar manufacturers produce various products. Among all this variety, there are several popular brands of warm plasters:

- Knauf grunband - one of the most famous types of plasters. It is made on the basis of polystyrene foam filler. The fraction of balls does not exceed 1.5 mm. The manufacturer also adds various types of plasticizers and water repellents. After hardening, the top layer of plaster forms a unique decorative surface. Subsequently, it can be painted with special paints that will protect the surface from climatic influences. Its use indoors is not recommended. To obtain optimal thermal insulation performance, the mortar should be applied in a layer not less than 1 cm thick, but not more than 3 cm.

- UMKA UB-21 TM. Universal heat-insulating plasters that perfectly withstand significant temperature changes. The applied layer of the substance is able to withstand up to 35 winter cycles. It is made on the basis of a cement-lime mixture with the addition of foam glass. The product can be applied to almost any mineral substrate. Perfect for any kind of work. The materials are also good at repelling water, which allows you to protect the main surface from its effects. Another advantage is the quality of sound insulation. But if you use it for interior walls, then after hardening, the surface will need to be additionally covered with special putties.

- "Bear" - another good variety of solutions of domestic production. According to customer reviews, it tolerates frosty winters well. The advantages of the products include low thermal conductivity. It is versatile as it can be used in various temperature conditions.

- HAGAst AuBenputzPerlit FS-402. The main constituent elements here are cement and perlite sand. Compositions are intended for processing aerated concrete and gas silicate blocks. But they are also suitable for bricks and wood concrete. The only drawback is the inability of the plaster to withstand external influences. Therefore, it should be additionally filled with protective solutions.

- UNIS TEPLON. The compositions are intended only for interior work, since the main binding element here is gypsum.Small perlite sand adds insulating properties to it.

The manufacturer recommends covering the walls with this plaster layer, the thickness of which does not exceed 5 cm. If you need to increase this indicator, then it is better to use a special reinforcing mesh. The composition is very well applied and does not require external puttying. After hardening, the plaster can be wallpaper-pasted or painted.

Helpful hints and tips

Working with warm plasters is relatively straightforward.

To get a durable and even coating, several rules should be followed:

- To install the beacons, use the same mixture that will be used for plastering. If other products are used, they can lead to the formation of cold bridges.

- The final alignment and removal of the beacons should be carried out within 2 hours after plastering. If this is not done, then the solution will harden and lose its plasticity.

- The mixtures should be applied in layers, the thickness of which does not exceed 2 mm. This approach will give you more flexibility in leveling the surface.

- Be sure to follow the manufacturer's recommendations when mixing components. Do not leave the ready-made solution for future use, as it will lose its original properties.

Warm plasters are another way to transform a building into a warm and pleasant home. Choosing the right product will allow you to get a reliable surface that will last a long time.

All about warm plaster ThermoVer see below in the video.

The comment was sent successfully.