How long does the putty dry?

Puttying is the final stage of preparatory work, which precedes wallpapering or painting the floor, ceiling or walls. In order for the repairs made to last for a long time and go as easily and quickly as possible, it is necessary to take into account such a factor as the time it takes for the putty to dry.

If the surface treated with it is not completely dry, it is impossible to continue the repair work, as it is possible to spoil the finishing material, which can be quite expensive. It can show annoying swelling, unsightly spots appear, the material can simply peel off from the rough surface. Therefore, you need to know what types of putties exist, and what are the features of their drying.

On what circumstances does the drying time of the putty depend?

Any type of putty is a water-based mortar. It is the liquid consistency that makes this material so convenient for construction and repair work. When the liquid evaporates during drying, the putty manifests itself in full - it hardens and becomes strong. The conditions of the environment in which the leveling compound is used have a direct influence on the drying time.

Manufacturers do not recommend going beyond a certain temperature range and humidity corridor.

There are such standards for the use of putty:

- It is better for the substance to dry within the temperature range from 5 to 25 degrees above zero;

- If this temperature cannot be maintained, the strength characteristics of the putty after drying will be unsatisfactory. For harsh climatic conditions, special frost-resistant additives are used;

- If drying occurs in extreme heat, it will be very quick but uneven and the finish will likely suffer.

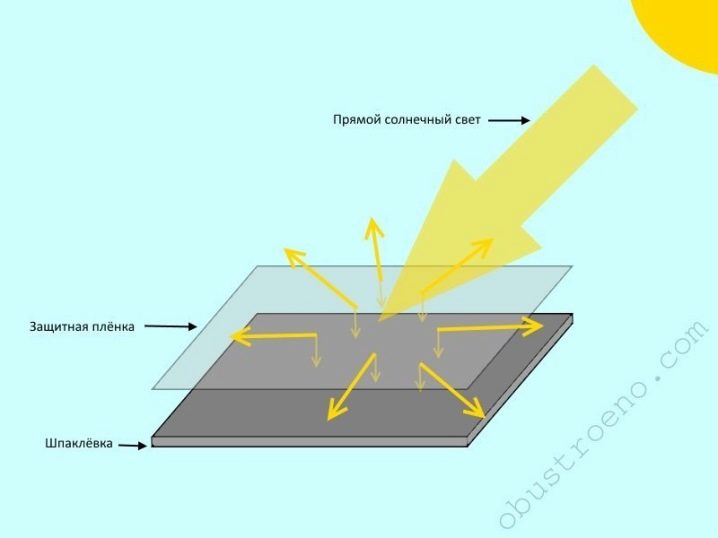

Never expose the drying material to direct and intense sunlight. If conditions do not allow the putty to be safe, a top coat can be used. It is also used before wallpapering.

The moisture level optimal for normal drying of the material should not exceed 50%. Drying will be extremely slow at higher (up to 80%) humidity values.

In order for the putty to dry as quickly as possible, it is also recommended to provide ventilation of the room, but at the same time it is necessary to exclude drafts, especially if the weather is windy.

The speed of drying of the material on the treated walls also depends on other factors:

- Layer thickness. The thicker it is, the longer it will dry. If you want the coating to come out of high quality, it is better to lay the putty in thin layers that will overlap as it dries. This technique takes more time, but it is fully justified by the high quality.

- Absorbent capacity of the prepared surface. The more porous the wall is, the better it will "absorb" the moisture of the material. This will provide faster drying, but this may not be desirable. In order not to accelerate drying in this way, it is recommended to use a primer.

Always pay attention to the instructions from the putty manufacturer.There are indicated not only the rules for application, but also the drying time of the material. Most often, the manufacturer recommends applying the material to a perfectly dry substrate with a layer of up to 2 mm. This layer will dry for about a day. If thick layers are required, drying time can take up to a week.

Another key factor that greatly influences the drying of the putty is its type.

The main types of filler materials

Leveling mortar compositions have different binding additives. The most common types of fillers for walls and ceilings are gypsum, cement, universal, as well as polymer (acrylic and latex).

What are gypsum mixes?

Gypsum putty can only be used in conditions of low humidity and only for interior decoration. Due to its increased hygroscopicity - the ability to "pull" moisture from any media with which it interacts, gypsum will simply fall off the surface if the air is not dry enough.

Gypsum leveling material is prized for its easy and quick application, the ability to adhere perfectly to the base and the inability to shrink. Plaster based putty dries faster than all other types of leveling materials. A layer that is not too thick dries and becomes hard after 3-6 hours. It is recommended to apply the plaster mix in several coats for perfect results.

When using a gypsum-based leveling material, you need to remember that the prepared mortar should be used as soon as possible due to the short hardening time. This can be difficult as there are many portions to cook.

How do cement putties behave?

The cement-based material will dry for a whole day. The recommended thickness of one layer when leveling walls or other surfaces is up to 4 mm. Despite the too long drying time, cement mixes are quite affordable.

A cement leveling mixture is used if:

- you need to get a solid, sufficiently hard surface for the finish of porcelain stoneware, tiles or masonry;

- facade work is in progress;

- finishing work is carried out in conditions of high humidity and strong temperature fluctuations (here cement will be an ideal choice);

- cracks, large gaps or tile joints must be repaired.

Despite the long period of complete drying, cement mixtures are excellent for many types of work, and for some they are simply irreplaceable. They are widely represented on the market and do not require significant financial investments.

Polymer putty

Leveling compounds, which contain acrylic or latex, tolerate conditions with high humidity. That is why they are suitable for both indoor and outdoor renovation and construction work.

Despite the indicated advantages, such materials have a significant disadvantage - a high price. For this reason, they are only used where only final work is needed.

The main advantage of polymer mixtures is their high elasticity. Due to it, during drying and hardening, the coating is not damaged or deformed. They are easy to apply in very small layers, the thickness of which rarely exceeds 1 mm.

This type of leveling compound dries very quickly, which is also an undoubted advantage. As a rule, it is enough to wait up to 4 hours to proceed with the final gluing or painting.

Polymeric materials for leveling are good because, unlike quick-drying gypsum, they can stay in an already open container for up to several weeks.

What can be used for plastic work?

For such work, specially designed putties are used. As a rule, they are used to paint plastic machine parts.The range of such materials is really wide. These are materials that have a phenomenal drying speed - from 20 to 30 minutes.

Are there quick-drying universal putties?

If the timing is extremely important for you, and circumstances do not allow waiting for the putty to dry, you can use special quick-drying leveling compounds. However, it must be borne in mind that their quality will be worse than that of all the materials discussed above. Speaking of the advantages, one cannot fail to note the ability of such a mixture to fit well on any base.

It is an excellent choice for rooms with high humidity - for baths, kitchens, showers. For other types of leveling compounds, such rooms are not suitable, while station wagons will successfully cope with this task.

The drying time for such material for damp rooms is indicated on the packaging. If the layer is thinned, it usually dries in 10 minutes. But if you need to get a thick enough layer, you will have to wait up to 2 hours.

Having good adhesion to metal, concrete and wood substrates, the universal mixture fills in all existing irregularities and imperfections.

Another undoubted advantage of this putty is the ability to easily adjust the degree of viscosity of the mixture. It is only necessary to dilute the material with the required amount of water to obtain a mass of the desired consistency.

Acceleration of drying of leveling compounds

As noted above, speeding up this process is highly discouraged. When using any heating units and tools, the surface will dry "in pieces", that is, very unevenly. This will damage the coating.

It should be borne in mind that if this method is used, then the layer on top is first of all exposed to drying. Only the finishing coat can be artificially heated, while coatings with a starting putty cannot be heated.

What is the technology for applying leveling compounds?

The final stage of preparing the base with putty takes place in the following sequence:

- first, the surface is cleaned of the previous coating;

- dust and grease must be removed, existing cracks are sutured;

- repairs should be planned so that the ambient temperature is not negative or too high, and the humidity does not exceed normal values. If these conditions are not met, drying will take longer;

- the base must be primed so that it does not "draw in" too much moisture from the putty mixture, which is thus saved, does not crack and hardens better;

- the starting mixture must be used to eliminate the roughest irregularities;

- it is better to divide the work into stages, first applying one layer over the entire area of the room, and then subsequent ones as the first dries;

- after the base is completely dry, it must be sanded to achieve maximum smoothness;

- at the next stage, the finishing mixture is applied, the layer of which should not be thick;

- at the end of the work, the finishing material is sanded using fine sandpaper.

Summing up, it should be remembered that the choice of a leveling mixture largely depends not only on the type of base, but also on the conditions of the environment in which the repair is made. Each type of material has its own drying period. It is undesirable to accelerate such drying in order to avoid damage to the putty layer, its cracking and subsequent damage to the finish.

For information on how to level the walls with putty, see the next video.

The comment was sent successfully.