Grinding machines for wood: features and subtleties of choice

Grinding machines for wood are called an important and multifunctional tool. They are often used during construction, renovation, and restoration work. To date, the assortment of this product is quite extensive, the tools may differ in design, purpose and method of application.

Peculiarities

Sanding wood surfaces is not a simple process. Manually, this type of work cannot be done perfectly, so using a wood sander will be quite appropriate.

The advantages of grinders include the following characteristics:

- high speed of work on grinding surfaces;

- little physical effort;

- high quality of the surface that is obtained after work;

- additional functions that ensure the uniformity of the surface layer;

- the presence of a dust collector, which makes the work neat and clean;

- a wide range of models, which contributes to the correct selection of tools for a specific material and task;

- various areas of use of the grinding machine.

There are few disadvantages of this tool:

- step-by-step performance of work, change of disks in the process;

- the presence of "dead" zones after processing, which have to be finalized manually;

- dependence of price on quality, cheap goods subsequently require more frequent repairs.

The grinder has the following elements.

- Engine. It can be not only a collector, but also a collectorless type.

- Nutrition can be network, battery or pneumatic.

- Platform for work. On this part, attachments, removable sheets, discs are fixed.

- Lever. There are models with both one and several handles.

- Control system, where the function of turning on, turning off, regulation of revolutions is turned on.

How does it work?

The work of the grinder on wood material is based on the effect of friction of the device against the material being processed.

The tool can perform its function according to the following principles:

- vibration, which is characterized by forward and return movements;

- circular, when the movement is carried out about the axis;

- combined, in which the first two types are combined;

- linear, which is typical of tape-type tools.

Work with this tool is carried out in the following stages:

- connecting the grinder to the mains;

- implementation of a comfortable hand grip;

- turning on the tool;

- waiting for the set of revolutions of the unit;

- bringing to the surface, where the processing and the process itself will be carried out.

Grinding devices are used with different types of attachments, thanks to which the processing of certain materials occurs.

What is it used for?

Wood grinders are quite common in everyday life and at work. The help of this tool lies in the processing of the material, its leveling, and the removal of old coatings. Using a sander, the master can quickly and efficiently sand and polish walls, floors, restore old furniture, brush wood, and remove varnish and paint.

For each type of work, you can make a selection of the tool model.The devices are capable of performing rough grinding, eliminating irregularities.

Views

There are many types of wood sanders. They perform similar functions, but differ in the final result. On the market you can find professional, hand-held small grinders, drum, circular, flat, electric, disk. All of them perfectly fulfill their tasks and are indispensable devices both for household needs and in the field of professionals.

The main types of tools for processing wood.

Angle grinder

The use of a grinder for work, which is associated with sanding and processing wood surfaces, has been popular for many years. This is a fairly functional tool that easily aligns materials with large dimensions. Of the shortcomings of the operation of such a device, one can single out not the ideal evenness of the surface according to the result of the work. LBM will be an excellent option for log cabins, but not for carpentry work. This is a circular disc typewriter, the nozzles of which can be easily changed.

Petal, disc-shaped circles are the most successful options for this work. Intermediate as well as coarse sanding can be performed when changing attachments.

Tape

The belt sander is so named due to the presence of sandpaper, which is in the form of a belt. The latter carries out continuous movements due to the presence of rollers. This kind of tool is worth using for rough alignments of materials. In order for the surface to be perfectly processed, you will need to use additional equipment. Longitudinal scratches can be removed by step sanding with repeated grit changes. The main advantages of the belt-type tool include good performance. Among the shortcomings, one can single out the inability to get all the structural elements, for example, corners.

The second disadvantage is considered to be a rather large weight of the machine, which causes certain difficulties during operation. Also the grinder is quite noisy, so you must wear headphones when using it. For a shallow depth of grooves, drive the instrument along the fibers. Minor drawbacks of the tape device are insignificant, since the device is functional and productive, therefore it is quite in demand among the consumer.

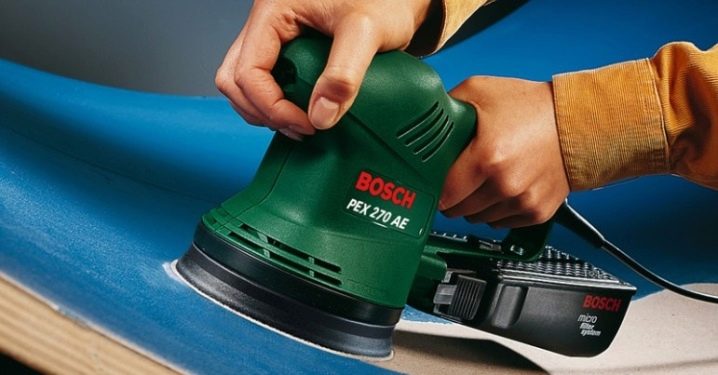

Orbital

The orbital machine is equipped with a round base and Velcro, where the sandpaper is attached. The discs for such a machine can be easily replaced. The outsole is equipped with many holes through which dust escapes. Litter is collected in bags and cassette-type containers. The operation of the orbiter is based on rotational movements. Thanks to this work, the optimal speed of woodworking is ensured. During the use of the tool, spiral and orbital movements of the platform are performed. This type of tool is lightweight, quiet and easy to use.

Even the corner of the machine can handle a hard-to-reach place, for example, a notch, a cut. The processing of a large wooden surface is also within the power of an orbital sander. Having installed coarse sandpaper on it, the unit can be used for coarse and intermediate sanding. The speed is slightly inferior to the previous version, but users note that it is quite sufficient. The disadvantages of the tool include the inability to process wood in the corners.

Vibrating

This tool is equipped with a rectangle or triangle sole. During its operation, movements occur in a circle, the device vibrates. This type of tool is an excellent option for finishing, under varnishing, before painting. It has a low level of performance. The machine, which is equipped with a rectangular platform, is capable of processing large areas of materials, but it does not make it possible to sand wood near a wall or vertical surface.The triangular platform option is ideal for corners and hard-to-reach places.

Subject to the ingress of grains of sand or solid elements during processing, small circles may remain on the material. This is why the surface must be thoroughly cleaned before starting sanding work.

Oscillating

The device does not belong to wood sanders, but it can perform their functions. The tool has such a grinding ability that is not inherent in other grinders. When installing a triangular sanding platform, the device helps surface treatment in corners and hard-to-reach places. The machine's capabilities include not only removing wood, but also glue from the surface.

Rating of the best models

Hand tools that cut wood pieces work by removing a small layer of wood using the motion of an abrasive tool. Design features make it possible to divide grinding machines into several types.

Household

These are inexpensive options for tools that have limitations in engine power, short-term operation, and limited functionality.

Popular models for the home.

- "Caliber LShM - 750" - a machine with an affordable cost and good features. The tool is equipped with a high power electric motor. The device has found application in the processing of wooden parquet and timber. The machine is able to remove varnish, paint, clean wood pile. The tool is compact in size, you can adjust the position of the abrasive belt. The disadvantages of the model include noise and rough appearance.

- Bort BBS - 801N 93728007 ideal for home use and renovation work. This hand-held unit is able to grind wood blanks, prepare the floor, and assist in the repair of furniture. The machine has a mechanism that adjusts the processing speed. The advantages include the presence of a dust collector, as well as universal use. With a well-thought-out design and efficiency, a sander is not worth much. The disadvantages of the device include poor fixation of the cover.

- Patriot BS - 810 Is an efficient belt sander with good performance. Using the tool for a short time, it is possible to process a large area. This equipment option will be optimal for working with wooden buildings. The electric motor contributes to the duration and efficiency of the work, in addition, the machine is equipped with a comfortable grip and a locking system. Its advantages can be called lightness, power and reliability, and its disadvantages are the length of the cable, which is often not enough.

Professional

Wood-working machines, which can be produced not only in China, but also in Germany, can have professional characteristics. They have a large motor resource, they can function for a long time. The equipment is adapted to the processing of surfaces with a large area, therefore, it is characterized by extensive functionality and a powerful engine. Review of the best models of professional grinders.

- Black Decker KA 88. The tool can be classified as a draw frame. It is able to adhere tightly to side surfaces, as well as handle furniture boards, parquet floors and wall cladding. The peculiarities of the housing allow processing of corner joints, as well as protecting the walls from damage. The main characteristics of the instrument are extremely strong body, lightness, long cord. The disadvantages include the difficult process of changing the brushes and the features of the belt.

- Ryobi EBS 800 V Is a type of professional equipment in which you can adjust the position of the support handles. Everyone can change abrasive belts. The tool is characterized by endurance, reliability, high processing speed, and overheating protection.The machine can be conveniently used for sharpening cutting surfaces, it is characterized by productivity and versatility. Of the shortcomings, users note clogging of the dust collector channels, as well as the need to lubricate the bearings.

- Makita 9910 is a machine from the professional series, it is distinguished by high-quality balanced units, ergonomic handles and cases. The complete set includes a bulky bag that collects shavings, dust. The start button has the ability to lock. Changing the sanding belt is quick and easy. The stroke of the abrasive tool is quite accurate. The tool is in demand due to its simplicity and ease of use, even with one hand. The machine is characterized by reliability, build quality, body comfort and good balance. The disadvantages include low power, lack of speed control.

- Hitachi SB8V2 is a device that is equipped with a powerful engine. He is able to work with wood of different density and hardness. The car proved to be excellent in removing the previous coating. It is characterized by the presence of electronic regulation of the speed of revolutions. Thanks to the design feature, it became possible to process wood close to the sides of the surfaces. The advantages of the device include power, the ability to process oak, beech, larch, the presence of a dust collector and a sturdy body. The disadvantages can be considered ill-conceived balancing, the complexity of vertical work.

Which one to choose?

Ideally, in order to carry out procedures with wood, several grinders are needed, one of which will carry out a rough finish, and the other one will finish. Coarse grinding is best done with a tool with an eccentricity of 6-8 millimeters, and for finishing sanding and polishing - 2-4 millimeters. With a limited budget, sanding surfaces can be done with a grinder. The most productive, but at the same time, the cheapest option is the vibratory sander.

If funds allow, then it is worth giving preference to the universal orbital option. Like any other tool, the wood sander is divided into several classes. The household version is designed for short-term intermittent operation. It is recommended to work with such equipment no more than 3 hours a day, while interrupting for 15 minutes.

A professional device is capable of functioning from 8 to 12 hours without interruption. These machines are durable, reliable, and have a good working life. Such equipment is quite efficient. The user has the opportunity to opt for a model with a dust collector, vacuum cleaner or linear motion.

It is necessary to choose a tool that will perform all the tasks assigned to it. The main criteria for choosing a tool include the following:

- power that has a direct impact on the performance of the equipment;

- the length of the cord - the larger it is, the more mobile the car;

- the presence of overlays on the handle, which improves ease of use;

- weight - using a heavy tool, you have to make more effort, but such machines are easier to operate;

- smooth start;

- the possibility of connecting a vacuum cleaner;

- regulation of engine speed;

- protection from overheating.

Operating tips

After purchasing a wood sander, you need to set up the tool correctly. To do this, install the tapes according to the arrows on the back. In the absence of these designations, the ribbons are set arbitrarily. The location of the tape should be strictly in the center. After installation, it is worth turning on the tool and checking it out.

Most grinders are sold with reservoirs that collect dust. If they are not available, the tool can be connected to the vacuum cleaner using an elastic tube. In this way, dust will be removed and may interfere with work.

To protect yourself from injury when using the grinder, you should heed the following tips:

- to prevent injury to the eardrum, it is worth wearing ear protectors;

- a respirator and a damp handkerchief will help protect against dust;

- so that shavings and dust do not damage your eyes, you must wear glasses;

- disconnect the tool before cleaning the dust container;

- before disconnecting the machine from the mains, you need to press the "disconnect" button on the machine.

Grinding machines are units that every owner needs. When choosing them, you should not take into account only the cost or external characteristics, but pay attention to the features of their further use.

For information on what types of grinders are needed to perform different jobs, see the next video.

The comment was sent successfully.