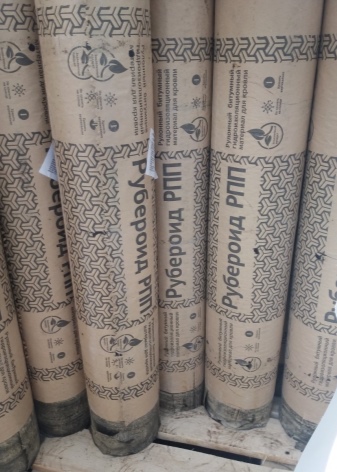

Roofing material of the RPP brand

Roofing material of the RPP 200 and 300 grades is popular when arranging roofing coverings with a multilayer structure. Its difference from the rolled material RKK is quite significant, as evidenced by the decoding of the abbreviation. When choosing the appropriate option, you should study in detail the marking features, technical characteristics, the weight of the roofing material roll and its dimensions in order to avoid possible errors.

Specifications

Roofing material RPP with a value of 150, 200 or 300 in the marking is a roll material manufactured in accordance with GOST 10923-93. He sets the dimensions and weight of the roll, determines what characteristics it has. All roofing materials produced in Russia are marked in a certain way. It is on this basis that you can understand what kind of purpose the coverage will have.

The abbreviation RPP means that this material:

- refers to roofing materials (letter P);

- lining type (P);

- has a dusty dusting (P).

The numbers after the letters indicate exactly what density the cardboard base has. The higher it is, the stronger the finished product will be. For RPP roofing material, the density range of cardboard varies from 150 to 300 g / m2. In some cases, additional letters are used in the marking - A or B, indicating the time of soaking, as well as its intensity.

The main purpose of RPP roofing material is to form a lining under soft roofing coverings such as ondulin or its analogues. In addition, this type of materials is used for 100% waterproofing of foundations, plinths. The main characteristics of the material are as follows:

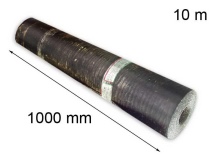

- width - 1000, 1025 or 1055 mm;

- roll area - 20 m2 (with a permissible deviation of 0.5 m2);

- breaking force when applied to tension - from 216 kgf;

- weight - 800 g / m2;

- water absorption - up to 2% by weight per day.

For RPP roofing material, as well as for other types, it is imperative to maintain flexibility throughout the entire period of its storage and operation. The material is covered with a dusty dressing made of glass magnesite and chalk so that its layers do not stick together. Its obligatory properties include heat resistance.

Transportation of rolls is allowed only in vertical position, in 1 or 2 rows, storage is possible in containers and on pallets.

How is it different from RKK?

Ruberoids RPP and RKK, although they belong to the same type of material, still have significant differences. The first option is intended to create a backing layer in multi-component roofs. It does not have high mechanical strength, it has a dusty dusting.

RKK - roofing material for the formation of the upper roofing coating. It is distinguished by the presence of coarse-grained stone dressing on the front side. This protection provides an increase in the functionality of the coating.

Stone chips well protect the bitumen layer from mechanical damage, exposure to direct sunlight.

Manufacturers

Many companies are engaged in the production of RPP brand roofing material in Russia. One can definitely include TechnoNIKOL among the leaders - a company that already occupies one of the leading positions in the market. The company manufactures products in rolls with the RPP-300 (O) marking, intended for waterproofing basements and plinths. The material is characterized by increased strength, affordable cost, withstands heating up to +80 degrees.

The enterprise KRZ is also engaged in the production of RPP roofing material. The Ryazan plant produces lining materials in the middle price category.The company specializes in the RPP-300 brand, suitable for the formation of a base for a concrete screed, underfloor heating. The material from KRZ is flexible, easy to cut and install, has sufficient strength.

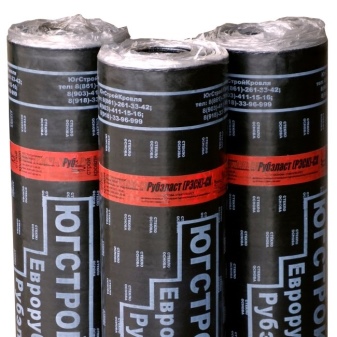

Particularly noteworthy are the RPP roofing materials produced by the firms "Omskkrovlya", DRZ, "Yugstroykrovlya"... They can also be found on sale at building supplies stores.

Laying procedure

Installation of roofing material of the RPP type implies following a specific procedure. Material in rolls is delivered to the work site in the required quantity. A preliminary calculation is made of the amount of roofing material sufficient to completely cover all surfaces of the roofing cake.

The choice of suitable weather conditions is of great importance. You can work only in dry weather, it is advisable to choose a cloudless sunny day. Consider the order of work when laying the roofing layer.

- Surface cleaning. The roof section is freed from dirt and dust, the rafters are prepared, allowing you to rise to the desired height.

- Application of mastic. It will increase adhesion to the surface, provide a better fit of the material.

- Next, they begin to roll out the roofing material. Its laying is carried out from the ridge or the central part of the future coating, with the side without sprinkling to the mastic layer. At the same time, heating is carried out, which allows the material to be melted onto the surface. Work continues until the entire roof is covered. At the joints of the rolls, the edges are overlapped.

When waterproofing a foundation or plinth, the sheets can be fixed in a vertical or horizontal plane. Each of the methods has its own characteristics. With horizontal fastening, RPP roofing material is attached to mastic on a bituminous basis, with a margin of 15-20 cm. Upon completion of construction work, you need to fix the remaining edges of the material, bend them up, and fix them on concrete. This method is usually used during the construction phase to protect the foundation.

Vertical waterproofing using RPP roofing material is made to protect the side surfaces of concrete structures from moisture. A bituminous liquid mastic is used here as a kind of adhesive composition, applied over a special primer to increase adhesion. Installation is carried out with an overlap, from bottom to top, with overlapping adjacent areas by 10 cm.

If the water table is high enough, the insulation is applied in several layers.

The comment was sent successfully.