Self-adhesive roofing material: composition and application

Ordinary roofing material is not enough just to lay. He needs additional protection - a separate waterproofing due to the gaps between the sheets. Self-adhesive roofing felt much better seals the space under it.

Peculiarities

Self-adhesive roofing material is a building material that is different from a simple roofing material that is placed around the entire perimeter of the walls under the first row of bricks. In addition to the adhesive surface, it has a polymer layer that makes it stronger and more elastic to tear. The only thing in common between self-adhesive and simple roofing material is the presence of bitumen and the production method.

Self-adhesive roofing felt is made from improved materials in the following way. Resin-containing impregnating ingredients are layered one on top of the other. And they are produced, in turn, from oil distillation products. They are applied to the base, which is a kind of buffer.

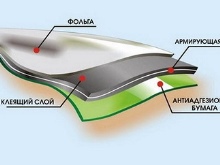

Layer-by-layer self-adhesive roofing material is represented by several technological layers, starting from the topmost one.

- Armored powder - a coarse-grained free-flowing medium, which is a mince. There are varieties of this building material, sprinkled with tinted granules, giving the roof a more beautiful look. Colored chips reflect up to 40% of sunlight. Armor powder is called armoring because of its ability to protect the base and impregnation from the destructive effects of ultraviolet radiation and excess moisture.

- Bituminous impregnation - Compared with standard road bitumen, for example, BND-60/90, the roofing felt composition has a noticeably higher softening and melting point. Bitumen is supplemented with rubber, which allows even better than without rubber fibers to be protected, for example, from frequent showers.

- Polyester base - this is the polymer layer, in comparison with which the cardboard base of a simple roofing material would long ago have been torn from a slight action on rupture or penetration. Polyester joints are ductile and flexible.

- On the other side of the polyester is located second layer of modified bitumen - it is he who is glutinous. For gluing, you need to wait until it melts under the influence of the street heat, so the work is done on a hot summer day.

- Film or foil prevents gluing of roofing material in a roll. Before installation, it is removed.

Lining roofing felt is produced with a double-sided self-adhesive coating. Accordingly, the film or foil is glued to it on both sides.

Self-adhesive roofing felt has significant - in comparison with the main - strength and durability. Its long, long-term service life fully covers the money spent - self-adhesive roofing material is up to three times more expensive than a simple cardboard one. The service life of the coating is up to 10 years. It is extremely easy to mount it - you do not need third-party heating from an open flame source. Installation is carried out with his own hands, in a short time. It will not be difficult to glue it to a wooden base - as well as to a metal one, the main thing is that the wooden flooring is smooth enough. If the wood is rough, then the master will have to properly press down and "tap" the newly laid coating. Roll weight is no more than 28 kg. The width of the strip in the roll is a meter, the length of the building material is no more than 15. Storage in any position will not have any effect on the safety of the roll: protective films will not allow the building material to irreversibly and irrevocably stick together.

However, roofing material is a combustible material. 180-200 degrees is enough for it to ignite. Combustion of the material is accompanied by toxic fumes. Bitumen foams during combustion, and its splashes scatter in all directions, which is fraught with burns to the skin of a person nearby. In order for the coating to be extremely reliable, sometimes the number of layers is increased to 7. So, to cover 15 m² of the surface, 105 m² of such roofing material may be required. The use of roofing material in the Far North can result in premature cracking: the polyester base and bitumen become brittle if it is -50 ° outside.

Applications

Self-adhesive roofing material is used for waterproofing all types of floors, for example:

- gazebos;

- auxiliary outbuildings;

- garages;

- country houses (especially small ones).

Despite the limited period of validity - maximum 10 years - self-adhesive roofing material will effectively save the roofing iron from rust from the inside, if the attic is not insulated. This building material tightly closes the inner (bottom) surface of the outer floor (roof) from water, fungus, mold and other aggressive media.

Laying technology

Increasing the durability, service life of a building or structure due to waterproofing from the outside and from the inside provides for the application of roofing material to the roofing cake above the kitchen, pantry and / or bathroom... The floor covering of self-adhesive roofing material is an attribute of the basement, cellar, over the entire area of the basement floor. Waterproofing prevents the main building materials from collapsing under the influence of condensation and negative temperatures.

The service life of the foundation is also increased.... The action of mold and mildew is prevented due to the decrease in humidity.

The indoor climate in the premises is favorable for humans thanks to the waterproofing layers.

Even a beginner can mount a self-adhesive roofing layer. Special skills and special tools are not required.

- First, the user checks the condition of the roof in general and the roof in particular.... Basic materials that have been significantly damaged due to corrosion over many years of operation are removed completely.

- In a satisfactory condition, the roofing material is laid on the previous roof base... The roof is cleared of dirt and debris. In the presence of a concrete floor, it is covered with a bituminous composition. Wooden rafters and lathing are treated with a fire-fighting compound and impregnation from fungus and mold, from insects.

- A roll of roofing felt tape is divided into segments, the length of which is not more than the length of the roof slope. Having straightened these pieces of roofing material, let them lie down in the heat.

- Self-adhesive is laid from the bottom of the slope, placing strips along the slope of the roof. The protective film is removed from the roofing material from below. By pressing the building material to the surface to be coated, they achieve the removal of air voids. The second strip (and subsequent ones) overlap the first, capturing at least 10 cm. This seam will provide moisture resistance. The coincidence of the seams - or rather, their flush arrangement - is unacceptable: soon the seam will be broken, and precipitation will penetrate downward, under the roofing cake.

The comment was sent successfully.