Everything you need to know about roofing felt

Many people cannot quite accurately and fully answer what it is - roofing material. In this case, they will be able to learn everything they need to know about the roofing material from the proposed material. There are different types of roofing material in rolls, and its brands differ.

It is necessary to take into account the characteristics of the material as a whole, as well as the features of the deposited material with chips and its other types.

What it is?

The name itself gives a brief understanding of what is to be dealt with. The exact meaning of this word is "rubbery". This is exactly the effect that the combination of Greek and Latin roots gives. Appointment of roofing material - roll roofing and the same waterproofing. The so-called roofing cardboard is taken as a basis. Each roll is made by impregnation with low melting point petroleum bitumen. The procedure, however, does not end there.

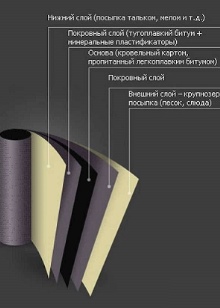

Further, the semi-finished product is coated on both sides with bitumen with increased refractoriness. Additionally, the material includes a dressing:

- talcum powder;

- asbestos;

- sand and other loose substances.

It is precisely because of such an additive that “something is constantly pouring down from the surface of the rolls,” which is extremely annoying for people. But you cannot do without it, since the absence of dressings leads to adhesion of layers. Almost everyone knows what roofing material looks like for a roof. Its production is deployed on a large scale. But less and less often there is a situation when roofing on large buildings would be made from roofing felt calculations - after all, this material has serious drawbacks.

Roofing material is relatively inexpensive and easy to install. It does not create a serious load on the base, and when covering an ordinary shed or utility room, you don't even need to do special calculations. Ruberoid roofing is more durable than roofing, and can be designed with any slope and geometry.

However, such material ignites easily. And it cannot boast of high strength. It is often found that the wind “shaggy” it in a matter of a couple of years, the frost makes it fragile, and the heat softens.

Specifications

With skillful use, roofing felt roofing will be relatively reliable. But in order to create and design it correctly, it is necessary to take into account the key features.... Sometimes roofing material is produced with special additives that reduce exposure to cold. Such products are used mainly in the northern regions. There it is guaranteed that the basic mechanical and moisture-protective properties will be preserved in frosts down to -50 degrees.

According to GOST, material bending around the rod 2-3 cm should not crack if the air temperature does not exceed +25 degrees. Deviations from dimensions are also normalized. You cannot sell rolls, the area of which differs from the declared value by more than 0.5 square meters. m. Deviations in width cannot exceed 0.5 cm. When roofing works use a thick (at least 0.4-0.5 cm) roofing material.

It is impossible to accurately characterize the service life of products. It strongly depends on the performance and various nuances of use. Classic material on a cardboard backing lasts no more than 5 years, even in favorable conditions. Reinforced rolls are usually designed to last 20-30 years. The same is stated by the suppliers of PVC-based membranes.

The density in kg m3 may vary slightly. The type of base, the thickness of the roll and the type of sprinkling play a role. The product complying with the national standard has a specific gravity of 25 to 30 kg. More precise instructions can be obtained directly from manufacturers and retailers.

In practical use, you should always pay attention to the vapor permeability coefficient and the melting point, which is usually 80 degrees.

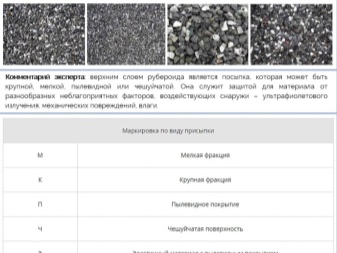

Overview of species by type of sprinkling

There are primarily 2 key varieties - front and lining (in roofing). Coarse dusting is done from only 1 edge. Such material is considered universal, its upper and lower layers are allowed. In another embodiment, a crushed stone is applied to the front plane, and a dust-like coating is applied to the lower one. This construction is optimal as a top roofing layer.

It is used as a top layer and a flake coating based on mica shale. Such a coating can be applied from 1 or 2 sides. Sand spreading is usually applied with 2 edges. This solution is suitable for both the base of the roofing cake and for waterproofing works. Any material can be used under a brick for the purpose of waterproofing. When covered with chalk or talcum powder, crushed to a pulverized state, it will be possible to equip only the lower tier of the roofing.

Marking

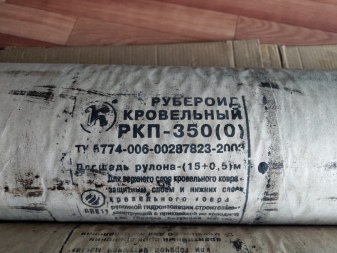

Deciphering the brand of roofing material is very simple if you know how it is drawn up. Everything is simple and logical here. In any case, the letter P is in front, which denotes the species type of material. The second symbol indicates the type of sprinkling. It can be M (small grains), P (dusty state), H (flaky design), K (large grains). The third letter speaks of the purpose for the roof (K), or for the lining (P). Then 3 numbers are given in the designation. They show what the density of the cardboard is per 1 sq. m. If the material is painted in any color, then it is additionally marked with the symbol C. The E index speaks of high elasticity.

Some manufacturers consider armored products with a density of 0.35 kg per 1 sq. m (for example, RM-350). But in reality, only products from 0.5 kg per 1 square meter have this property. m and denser. Such types of roofing material are in wide demand, such as:

- RCP-350 (dusty dressing, 0.35 kg per 1 sq. m);

- RKK-350 (the same density, large grains);

- RKK-400 (thick material covered with large dusting);

- RPP-300 and RPP-200 (product for lining with a dusty coating, which is used in waterproofing works).

Top manufacturers

A large company opens the rating of roofing felt factories Technonikol... Its advantages are already confirmed by the fact of shipment of products to 95 foreign countries and throughout Russia. This company has modern equipment and research facilities. In it, along with the usual roofing material, they also produce advanced versions of roofing materials. In the improved model, the thickness of the bitumen layer is increased on both sides.

In terms of practicality, products stand out favorably "Yugstroykrovli"... This company began its work in the 2000s, but has already managed to gain solid positions. The cost of production is quite decent. This material will not stick together even at solid air temperatures. It should be borne in mind, however, that official shipments to the center and north of Russia are not made. Since the beginning of the 1930s, the Myagaya Roof enterprise has been operating. Despite its solid history, it is adequately equipped. Now they have deployed automatic production lines.

The main emphasis in the promotion of products is made by the manufacturer on environmental safety and the availability of quality certificates. Shipment of products takes place in all regions of Russia.

Cardboard and roofing felt production is also in demand. "Omskkrovle". It was deployed back in the 1970s.Getting first-class bitumen from Siberian oil is an undoubted advantage. The products are resistant to cold weather and are very flexible, which motivates even consumers from the CIS countries to buy them. True, deliveries are not organized throughout Russia.

There are other good manufacturers in our country as well. For example, Ryazan plant KRZ... Its products are inexpensive and in addition are of good quality. The DRZ enterprise supplies both lining and high-density material. The second type is well suited for the finishing layers of the roof.

Selection Tips

If you need to pick up a durable armored roofing material, then you must definitely give preference to the colored variety. Only she will be sufficiently well protected from negative influences. Roofing material, which can be used to cover the roof as a finishing layer, can be made on a substrate not only of thick cardboard, but also of fiberglass. The classic cardboard base is still used today, but it is she who is recognized as a weak point.

In modern versions, asbestos or various polymeric materials can be used instead. According to the execution of the front covering, you can choose roofing material with:

- tar shell;

- a mixture of tar and bitumen;

- bitumen-polymer combinations;

- complex polymer compounds.

Such solutions turn out to be more reliable and more durable than simple bitumen. Regardless of the version, it is necessary to check compliance with the requirements of GOST. The assessment is carried out according to the presented certificate; if the supplier or seller refuses to display such a document, there is no point in cooperating with him. You need to pay attention to other points:

- the integrity of the edges;

- evenness of winding;

- good appearance (no visual defects);

- high quality impregnation;

- the condition of the packaging;

- quality of marking;

- reputation of the manufacturer and reviews about it.

Consumption

Determining the consumption of material in 1 layer is not difficult. As a first approximation, it can be taken equal to the area of the roof to be treated. But a one-layer calculation does not make sense. The smaller the slope of the roof, the thicker its protection should be in order to guarantee impermeability to water. On a flat roof, whose slope is no more than 3 degrees, it is necessary to place 3 levels of RPP-350 and 1 level of RKM-350.

If it is known that they will walk on the roof, they will already equip 4 underlying layers. In this case, they will tolerate both the load from movement and the impact of snow. At a 6-degree slope, you can limit yourself to 2 layers of bedding and 1 face level. With a slope of more than 15 degrees, roofing material is not used in its pure form, there it goes as a waterproofing substrate for corrugated board or slate.

We must also remember about the overlaps of the strips of 10 cm, about the 20-cm reserve near the slopes and skates and about rounding up.

Installation methods

Weldable

It is, of course, heated with a burner during installation. However, in this case, everything must be prepared in advance. All dirt, debris and, in general, everything that can interfere with the surface is removed in advance. Any mechanical defects are eliminated in advance. And also it is worth removing any rotting part.

The burner is attached to a hook. The fire is applied to the underside of the roll. The material should be rolled over the surface gradually - not too fast or too slowly. Recommendations:

- lead strips with an overlap of 10 cm;

- put the docking area higher so that the water can drain;

- before joining the canvases along the edges, it is advisable to warm up the docking strip and sink it in bitumen;

- the sealing of the seams in the longitudinal and transverse planes is carried out using a roller (this must be done while the material remains elastic).

Self-adhesive

As in the previous case, start with a visual inspection of the roof. It is advisable to dismantle all strongly deformed and swollen areas. The strips, cut exactly to size, are opened and allowed to rest in their proper places. Further:

- carefully separate the film;

- press the structure to the base;

- use a trowel or an unnecessary piece of cloth to smooth out the strip, expelling air bubbles;

- put the next strip with an overlap of 10-15 cm, thereby protecting the seam from water ingress.

Bulk

Work begins, again, with a thorough cleaning and drying of the prepared space. All uneven areas are removed with a special solution. During a major overhaul of the old roof, all exfoliated elements must be removed. Before applying bulk roofing material, the entire surface is supposed to be primed with mastic, previously diluted with a solvent according to the recipe. Processing is carried out only on dry surfaces. Each subsequent layer of waterproofing must also be pre-dried before continuing to work.

An important role is played by the metal roofing tape for fastening. It is very reliable and practical.... A tape like this is great for fixing to a wooden surface. A steel product (both with and without perforation) is durable and lasts a long time, you won't have to pay big money for it. Manufacturers have already worked out the production of tapes of various standard sizes.

In some cases, roofing material is attached to cold mastic. It is pre-melted... In this case, it is important to accurately capture the moment when the substance has already melted, but coking has not yet begun. Too long delay, you can get unusable bitumen. The molten mass must be mixed with a solvent until a completely homogeneous mass; The mastic must be brought to a warm (not hot!) state.

Roofing material can also be laid using a bitumen-based sealant. It is recommended to thoroughly clean the surface before applying it. Small volumes of sealing compound should be applied using a construction gun. Cracks and voids of great depth are closed in several stages.

The sealant that gets on foreign surfaces is immediately removed with a cloth soaked in solvent.

Storage rules

Roofing material should be sorted by brand before being stored. It is best placed in dry, closed rooms. The rolls are usually placed vertically, with a maximum of 2 rows in height. They can be placed not only on stone floors, but also in containers and on pallets. The standard shelf life of the material is 12 months. With confirmed compliance with GOST standards, you can use it after this time.

Disposal features

When using roofing material, its waste inevitably appears. And also a large number of them arise when dismantling old roofing structures. The composition of this material usually includes cardboard (13%), 57% of bitumen, and the remainder falls on the dressing. Classical and modern roofing material belongs to the 4th category of danger, that is, to waste that does not pose a particular threat. If recycling is not possible, storage at landfills is permitted.

However, this approach is difficult to consider the optimal solution. Making roofing material from oil takes up a lot of irreplaceable resources, and processing saves them. The cost of processing and the resulting products is low.

At the same time, roofing material stored at landfills will decompose for at least 100 years. Its decomposition products contaminate the soil and can get into ground or surface waters.

In the country house, roofing material can be used, as:

- mulch;

- tree trunks protection means;

- an improvised means of protection against rodents;

- device for keeping the roots of shrubs.

The comment was sent successfully.