Roofing material RKK 350

Roofing material as a material for arranging the roof came into use during the period of total shortage of the Soviet era, when the range on the market was limited by it and slate. In modern conditions, competition has increased, but this has not reduced the demand for this affordable but practical material. The roof covering RKK-350 has won the recognition of users, it is used to form the upper layer of the roof structure in utility buildings and structures of a similar purpose.

Specifications

It's no secret that the quality of the roof and the duration of its service directly depend on the performance characteristics of the materials used for its arrangement. In order for the roof structure to serve for at least 10 years, it is necessary to use high-quality coatings - these include RKK-350 roofing material. The manufacturing process of this material, as well as its thickness, dimensions and physical and technical properties are regulated by GOST and technical specifications (TU) adopted by the manufacturer.

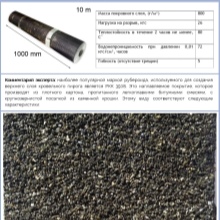

Each roll of RKK-350 has the following operating parameters:

- width - 1 m, the standards allow fluctuations up to +/- 5 cm;

- length - 10 m, the permissible deviation from this value should not exceed 5 mm in one direction or another;

- the area of the material of 1 roll is 10 m2, the parameter may deviate from this value by no more than 0.5 m2;

- 1 roll of RKK-350 has a mass of 27 kg, deviations of the mass from the regulated value are not considered a sign of marriage;

- the weight of 1 m2 of roofing must not be less than 800 g;

- roofing material of this brand has exceptional waterproofing properties - the water absorption parameter is 2% per day;

- in accordance with the requirements of GOST, the tensile strength cannot be lower than 32 kg / s.

We draw special attention to the fact that the characteristics of the RCC may deteriorate due to non-observance of the storage rules. When buying construction and finishing material in a trade enterprise, make sure that the rolls are upright.

If they were folded horizontally, then this leads to adhesion of individual layers to each other - such a roofing material is very difficult to roll out, and when separated, it can be torn.

Composition

The decoding of the RKK marking means: roofing felt roofing with coarse-grained dressing. The material is characterized by an increased degree of hygrostability, this is ensured by the multilayer application of several types of bitumen to the base.

Several components are used in production, they complement each other and thereby increase the technical parameters of the material.

- Coarse dressing - the surface of the RKK is covered with a granulate dressing, it is needed to protect the material from ultraviolet radiation, external mechanical shock and soaking. It has a silvery hue, thanks to which it is able to reflect up to 30–45% of the rays and heats up much more slowly than black.

- Refractory bitumen - the next layer consists of refined products with a dense structure and an increased melting point. The only drawback of this substance is that in the cold it becomes more fragile and cracked.

- Roofing cardboard - usually used cardboard, treated with low-melting bitumen. As a rule, the impregnation BNK 45/180 is used, it is distinguished by an oily consistency and black color. The moisture absorption of such cardboard is not lower than 1300%, and the soaking period is 50 seconds.

- Second layer of refractory bitumen - the bottom layer is required for installation of the RKK on the roof base. For this, the refractory metal is heated to 160–180 g., The material becomes sticky, and it is easy to fix it on the roof.

- Dusty dusting - consists of talcomagnesite, used to prevent the adhesion of roofing material during storage and transportation.

Scope of application

Exceptional technical and operational properties make RKK-350 roofing material a suitable material for the formation of a roofing "pie". It has the most advantageous characteristics in terms of price - quality. The main area of its application is considered to be waterproofing, as well as roofing works; roofing material is often used as a lining for a solid roof. Subject to compliance with the rules and periodic maintenance, such a coating can last at least 10-12 years.

At the same time, the roofing material is poorly protected from external adverse influences. So, already with a cold snap to -5 gr. it starts to crack when bent. This significantly limits the scope of its use in regions with a temperate climate. In cities and villages with severe winters, this roofing material is not recommended for use as the main roofing covering. At a temperature of 200-250 gr. RKK-350 starts to burn.

In addition, it is unstable to the action of fire, therefore it is not used in the construction of saunas, baths and any production workshops with an increased likelihood of a fire.

Laying technology

Roofing material of the RKK-350 category is referred to the category of deposited coatings, therefore it is used at the final stage of creating a roofing "pie". The advantages of such a roof are simplicity and high speed of installation. For laying, you will need a sharp knife, a gas burner, and bitumen mastic. Installation of roofing material includes several steps.

First, the base of the roof is cleaned of any dirt and debris, the remnants of the previous coating are removed.

Two layers of bitumen mastic are applied to the prepared surface and kept for a couple of days to dry completely.

Then, the lining material is fused so that the seams between the individual strips do not coincide with each other.

Next, put the roofing material RKK-350. Installation begins from the bottom, carefully unwinding the rolls across the direction of inclination of the slopes. To melt the material, first the base of the roof is heated with a gas burner, and only then directly the RKK.

Important: We pay special attention to the fact that installation work can only be carried out at an ambient temperature of 5 degrees. and higher. At lower temperatures, it will take a long time to warm up the roofing base and the bitumen itself.

The topcoat should be laid in one layer, it is fused on the backing sheets "in a ragged way" so that the seams of different layers do not coincide with each other. To ensure maximum roof leakage protection, the strips should be secured with 15–20 cm fly-fishing.

Each layer of roofing made of RKK-350 can replace at least two or three layers of lining-type roofing material, which has poor water resistance and low density. With the correct installation of the roof "cake" made of coatings impregnated with bitumen, it will last 12-13 years.

During operation, cracks may appear on the roof surface from temperature surges and shocks. To prolong the life of the structure, inspection and minor repairs should be carried out every year, sealing any defects that appear with liquid bitumen.

The comment was sent successfully.