Dimensions and weight of roofing material

Roofing material or roofing felt is a building material based on bituminous impregnation. Its purpose is to fence steel, concrete and cement, wood, brick and foam block from each other. Its first application is laying on the foundation under the first row of wall masonry.

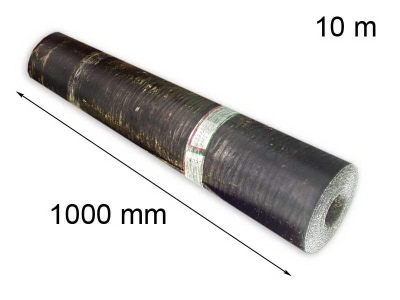

Standard sizes

Compliance with the standards of GOST No. 10923-1993 - the length selected for production (the number of meters in a roll of roofing material), the width of the strip rolled into a roll, and the thickness of the strip. Despite the strict regulations, most of the suppliers of roofing material produce it according to TU (technical specifications).

Width

The width of the strip of roofing material is one meter. According to TU, the tolerance is 5 cm in both directions from this value. Some of the building materials factories producing materials based on bitumen impregnation have established the production of roofing material with a strip width of 102.5 and 105 cm. The reserve is used to evenly overlap strips laid next to each other. The smallest possible width is 75 cm, this value is already a significant deviation (a quarter less), such a strip is used mainly on roofs of a small quadrature.

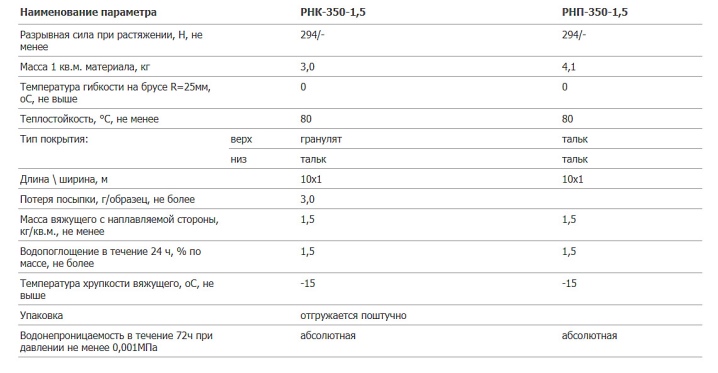

Savings for customers is achieved due to the absence of the need to cut into pieces a strip of excessive width, which would lead to a greater number of overlaps, since without them precipitation and melt water would penetrate into the roofing cake. Roofing paper of the brand RKK-350B, RKP-350B, RNP-350-1.5 (for the roof), underlain under the top and bottom of the roofing cake, has a width of 102.5 cm. The width of the lying roll is the height of the standing roll, placed on the edge.

Length

For length, the value according to the same GOST is normalized by ten meters. A tolerance of 5 mm is possible on both sides of this value. Shortage in length is not allowed: the discrepancy between the running meters will immediately reveal this. According to the TU standard, the production of rolls with a length of 15 and 20 m is allowed - one and a half and two times more than according to GOST. This reduces the cost of cutting finished strips of roofing material, packaging and stacking of this building material in warehouses.

15- and 20-meter rolls are predominantly lined roofing material: its running meter has less weight due to a decrease in thickness. For exclusive buyers with special requirements, they can produce rolls of any length in the specified range - cutting is performed only at the mark indicated by the client. The thickness and width of the roofing material, however, are not subject to individual measurements.

10-meter roofing paper - material of grades RKM-350B and RKM-350V. Scale-textured coating for soft roofing stands out, for which the roofing roll has a roll length of 20 m, its brands are RKCH-350B, RKCH-350V. The length of 20 m per roll is the lot of single and double-sided roofing tar, which is used as a lining for a roofing cake, its brands are RPM-300B, RPM-300A, RPM-300V. Roofing material with dust-like crumbs has a non-standard strip length - 15 m per roll. There are also 8-meter rolls.

Thickness

According to the same TU, the thickness of the roofing material starts from 2.5 mm. This value includes cardboard base and bituminous impregnation. It is not recommended to make roofing material thinner: when unwinding and even with the most careful unfolding, it will begin to break, which will dramatically worsen its insulating ability. To remove the resulting breaks, a resin (pure bitumen) is used. For roof waterproofing (including waterproofing the floor that acts as a roof), bituminous roofing paper with a thickness of at least 5 mm is used. 2.5… 4.5 mm bitumen is used as an additional lining.The density of the cardboard "rolled" into roofing felt is on average 250 kg / m3.

Square

According to the same GOST, when the size of a roll with a strip of 10 "squares" (1 * 10 m), the area should not go beyond this value. For a roll of 1 * 15 m - 15 m2, for 1 * 20 - 20 m2. According to TU, the length and width tolerance reaches values at which the actual area of the unfolded roofing material roll is greater or less than the GOST values for an area of 0.5 square meters.

How much does the material weigh?

The mass of a roll of roofing material is mainly determined by the size of the roll and texture, the thickness of the roofing itself. The texture of the roll is the granularity of the sprinkling: the latter is needed so that the roofing does not slip, but forms a reliable grip. An ordinary roll of roofing paper weighs at least 25 and not more than 30 kg. The weight of roofing roofing with coarse-grained dressing (for roofing cake) is greater. The lining roofing paper has a noticeably less weight.

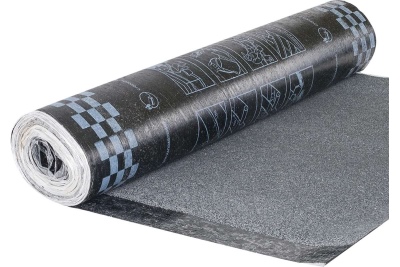

Roofing sprinkling is a crushed fraction applied on both sides of a strip of roofing material. In addition to adhesion, it prevents moisture from penetrating into the material and further, under it. The crystals with which the cardboard impregnated with bitumen is sprinkled remove water from the base material, it flows around them and flows down, is torn away from the roofing.

They also prevent the coils of the roofing strip from sticking to each other - especially in the heat, when the building material is kept in a steel storage.

Although bitumen itself at room temperature should not absorb and transmit moisture, the role of the crumb is not limited to adhesion to the surface to be laid and waterproofing. It makes the material coarser and thicker. Spreading material - quartz sand with a grain size of up to 1.2 mm per granule, marble chips, asbestos-pebble crushed or crushed roofing slate. Roofing material with quartz is much more expensive than its other types than shale roofing felt.

In addition to crumb, a cardboard tube can be another material in the composition of a skein of roofing material. The whole skein is wound on it, like on a reel. This makes it easier for loaders to carry such coils, moreover, they can be fixed on the side pin stops, which prevent the coil from slipping during transportation. The total weight of the skein may increase by a maximum of half a kilogram.

A tube made of cardboard, on which the roofing material is wound, prevents the material from wrinkling when winding up. If it were not for it, the roofing material, due to sharp bends, would partially lose its waterproofing properties. The fact is that the layers (bitumen impregnated cardboard, powder) in total have a certain fragility. The tensile strength is only 300 grams of tensile force per linear centimeter, regardless of the longitudinal or transverse tensile tension - in relation to the strip of roofing material. The diameter of the tube, which acts as a coil for the coiled roofing felt strip, does not exceed 3 cm.

Finally, unrolled roofing material has a specific gravity or density of an average of 350 grams per square meter. The volumetric weight of roofing material is on average 1750 kg / m3: the weight of one stack of rolls of lining roofing material, which does not have a cardboard tube in the middle, will take up more than a cubic meter of space. Knowing the average "area" (not to be confused with volumetric) roofing material weight of approximately 300 g / m2 (lining material), we get 5833 m2 of roofing material. The strip with a width of 1 m at a value of 300 g / m2 will stretch for almost 6 km.

You can calculate the weight of roofing material using theoretical and practical methods. Theoretical is one of the most difficult methods. The type of building material is taken into account - the packaging has data printed on the label about the weight of a square meter and the total mass of the entire roll, the number of layers of building material, the percentage (by weight) of bitumen or mastic that adheres the layers and the thickness of the material. The mass of each of the layers, obtained thanks to the initial data or the practical measurement of each of them, has a separate value. By adding these values, we get the weight of the roofing material.

The practical method is more precise and simpler. When disassembling the old coating, cuts are made on a square with a side of 10 cm. During the cut, the number of real layers of roofing material is considered (if it is more than 1). The length and width of the roofing space covered with roofing material are measured, the area is calculated. The number of layers of roofing material is multiplied (in thickness) by this value - this is how the real volume occupied by the roofing material is calculated.

The resulting volume is multiplied by the average density of the building material - the total weight of the building material that needs to be replaced is calculated.

The weight of roofing material must be known for the following reasons.

- Determine by the mass of one roll of roofing building material - how many of these rolls will be required in total.

- Knowing the number of rolls, an estimate is calculated for roofing work to replace roofing material. The cost of a roll is multiplied by their number - the total cost of roofing material (roofing felt) is calculated.

- The data obtained will allow us to estimate how much it will cost to deliver the rolls. If the delivery is carried out not within the same city, then the payment for delivery will be debited from the client separately.

The parameters of the roofing material (weight, dimensions of the strip and its thickness) are the initial data, without which it is impossible to calculate how much money will be spent on replacing the old coating with a new one.

The comment was sent successfully.