What is a rasp and how do I use it?

Wood is considered a durable and pliable material, so making various products from it is popular both centuries ago and today. With the development of this direction, tools for woodworking have been modified and improved. Today, every carpenter has the necessary set of tools, in which a rasp is necessarily present. The latter is characterized by ease of use, affordable cost and versatility.

What is it and why are we needed

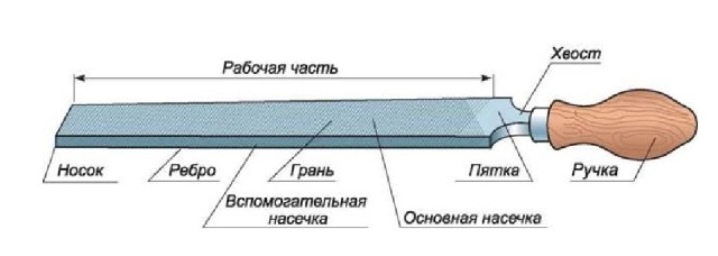

A rasp is a cutting tool with a large number of blades. This device may have sharp and large notches. It has found its application in the elimination of a coarse wood layer with its subsequent leveling, as well as in filing products and giving them a certain shape. This product is found both in garages and in locksmiths. It is considered universal, as it can be useful for roughing and primary work with wood.

The rasp can be used for processing wood, soft and finishing sheet materials. Due to the practicality of use in many technological procedures, this carpentry attribute has gained popularity among craftsmen. Its main purpose is considered to be filing, that is, the elimination of the surface layer from the workpiece, in order to subsequently give it the desired shape, size, roughness. The tool is necessary for quick, high-quality and easy removal of irregularities from any surface.

When using such a carpentry attribute, the processing accuracy can be about 0.05 mm.

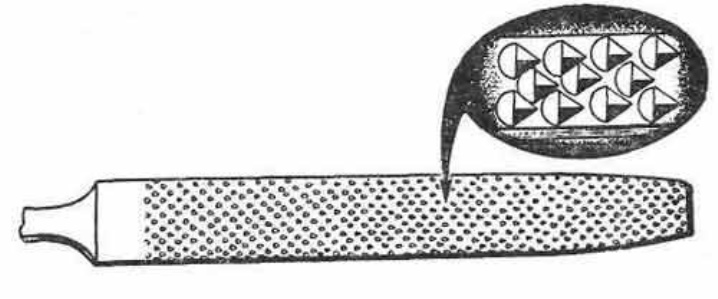

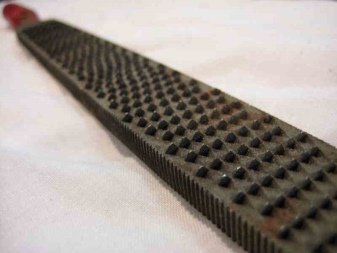

Despite the fact that filing is considered a laborious process, the use of a quality rasp can make the job easier, faster, and also eliminate the formation of defects. The main part of the design of the tool is considered to be metal teeth, which bear some resemblance to a grater. The working part of the device is made of steel, and the surface is produced by stamping notches and teeth. The latter are located towards the long side, overlapping each other.

To make the tool convenient to use, it has a handle. Usually it is made from hard wood or plastic.

Due to the peculiarities of the structure of the handle, the master is protected from injury and deformation of products.

What is the difference from files

A file, like a rasp, is a cutting tool. The difference between these devices lies in the arrangement of the working surface. The peculiarity of the rasp is the presence of convex triangular teeth, which are staggered. The file shaft is characterized by the presence of single or crossed flat teeth.

In addition, the following features can be considered the differences between the rasp:

- used for rough processing of material;

- has high performance;

- the presence of a massive body, which allows you to transfer more effort.

Experts say that when using a file, the processed surface is better than when working with a rasp.

Description of species

Rasps for metal, like other types, are divided into the following types, depending on the notches on the working surface:

- with a large notch in the amount of 8-12 pieces per cm2;

- medium - 12-18 elements per cm2;

- small - 18-22 elements per cm2.

On sale you can find a large set of carpentry rasps, which includes many of its varieties.

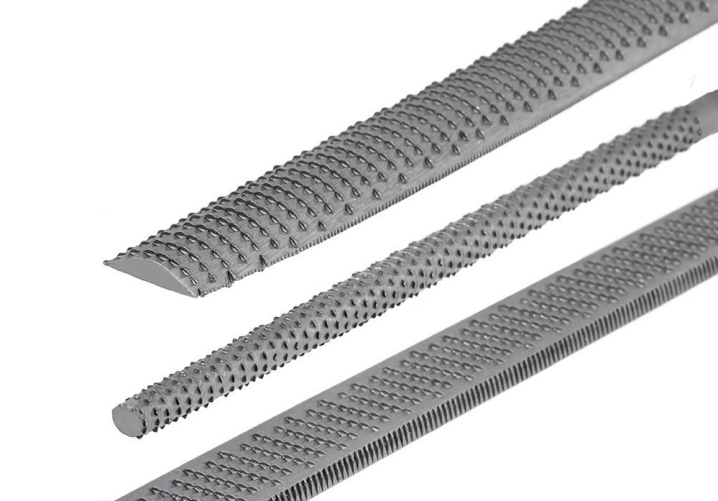

Flat

The flat rasp is usually used for concave surfaces. Thanks to the use of such a tool, burrs are effectively removed, as well as workpieces made of non-ferrous metal or wood are trimmed.

Modern flat rasp models have comfortable two-piece handles with hanging holes.

The working part of the carpentry attribute is made of high-strength steel, which is characterized by resistance to wear. Depending on the configurations, this tool can be either tapered or straight.

Semicircular and round

Round rasps have found their way into working on unstable metal or uneven surfaces. It is customary to use these attributes in the process of plumbing. Thanks to the ergonomic handle, the round rasp is quite comfortable to use.

Semicircular devices are used when cleaning and filing a flat surface. In addition, large-diameter holes are processed with these rasps. The handle of a semicircular product is usually anti-slip.

The models, as well as the purpose of such a tool, may be different, therefore the degree of its rounding differs.

Shoe

Shoe rasps are straight, curved, double-sided, one-sided. The use of such products contributes to the high-quality processing of products made from soft materials.

Since there is a wide range of rasps on the market today, it may be difficult for artisans to choose a tool. The size and other features of the notches on the device are selected depending on the type of work performed.

To cut rough material, a coarse rasp is required. In this regard, experts recommend having a set of rasps with different characteristics at home.

Manufacturing materials

Metal rasps, like files, are made of steel. In some cases, products are made of tool carbon steel, such as U10, U11, U12, U13. In addition, the basis of rasps is often alloy steel - ШХ6, ШХ9, ШХ15.

To understand how much carbon is in the rasp steel, it is worth observing the nature of the sparks.

A small amount of C2 will be expressed by sparks from the abrasive disc, which have a yellow-straw color and fan out.

High-carbon steels create sparks that separate a small number of sprockets from the bulge. The abundant release of many sprockets comes from the high carbon type of tool steel.

Long sparks of orange-red color appear from the chromium metal.

If high speed steel with chrome and tungsten was used in the manufacture of the rasp, then at the same time both short and elongated sparks appear, which have a dark red color and a thickening at the end.

Application features

Correct use of the rasp helps to increase its service life, and also prevents the likelihood of defects and breakages on it.

A medium-sized device should be used in accordance with the recommendations of specialists.

- To make the work more comfortable, the workpiece should be fixed with a vice or clamps.

- During work, the elbows should be placed on the vice jaws. In this case, the handle is held with the right hand, and the end is held with the left. Such a distribution of efforts can significantly increase the efficiency of the work performed.

- To eliminate the layer of material, the product should be carried out relative to the full size of the working part.If it is necessary to align a specific unevenness, it is worth using a short stroke.

- Craftsmen often use flat types of tools. When removing the top wood layer, the rasp must be guided diagonally to the grain. Do not forget that at the end of this procedure, traces may appear on the surface. The latter will disappear after finishing.

- In the first working stage, the craftsman must carefully press the rasp, as this manipulation will significantly increase productivity. At the end of the procedure, the pressure can be reduced and thus a high quality surface is obtained.

Basically, the nature of the use of the rasp is influenced by the peculiarity of the procedure being carried out. A well-finished surface is usually obtained from craftsmen with experience in carpentry.

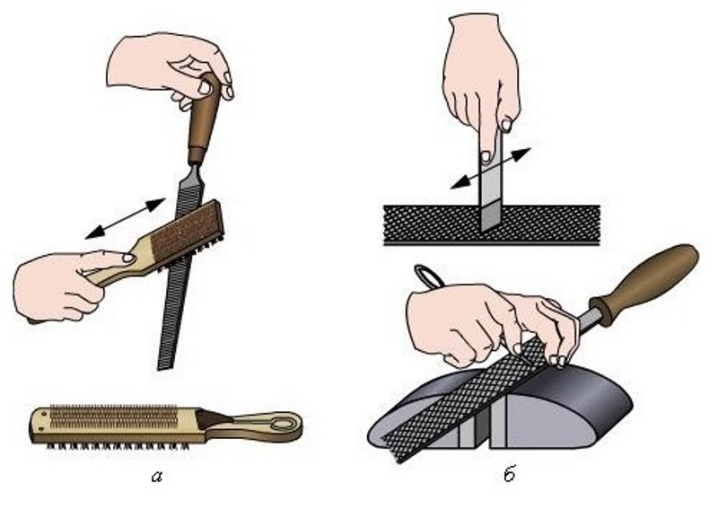

The tool must always be in good working order, ready for use. On a good, not worn-out rasp blade, defects are excluded, and on the handle - chips and cracks, the handle ring sits tightly into place. Working with the rasp should be accompanied by periodic cleaning using a wire brush. During work, do not put the tool on the edge of the workbench, it must be tightly packed in the tray.

Care Tips

The rasp, like other carpentry tools, needs constant maintenance, which can increase its service life.

We list the features of caring for this device.

- During operation, the grooves and notches of the material are often clogged. This nuisance can be manifested by the fact that the necessary layer of material is no longer removed from the treated surface. In addition, the rasp walks even when the master does not make any effort to do so. Clean the rasp by lightly hitting the surface. During the procedure, the master should be very careful, since a strong impact can cause the device to break.

- When the notches are clogged with chips, they can be cleaned with a regular brush.

- Before using the rasp, the craftsman should not place it on a metal surface. Otherwise, the cutting edge of the tool will wear out quickly.

- The rasp must not come into contact with lubricants. Even a small amount of this substance may impair the performance of the products.

After the work with the rasp is completed, the condition of the device should be checked. If even the slightest defects have arisen on it, then soon it will be necessary to change the product, as its functionality will be lost.

When working with plastic workpieces, it becomes necessary to eliminate synthetic chips. To clean the product, you will need to dip it into a container of boiling water. After softening the plastic particles and their lagging behind the notches, the instrument must be wiped with a piece of soft cloth, leaving it in the fresh air to dry.

After such an event, the tool should be lubricated with vegetable or machine oil.

A rasp is a rough type of file. Usually it is used when it is necessary to remove a thick layer of material from the surface. The ability to use such a device is considered to be a rather useful skill. It takes hard work and a little bit of diligence to become a rasp master.

Experts strongly recommend using quality rasp models, as poor tools can turn the workflow into hard labor.

What is a rasp and how to use it, see the next video.

The comment was sent successfully.