All About Spring Cotter Pins

Cotter pins are manufactured at the factory from wire with a certain type of cross-section, mainly semicircular. The use of material with a circular cross-section is allowed. The configuration of the finished product depends on the type of wire. Fasteners can be used in various areas of production with detailed assembly. The simplest thing is that the standard one is made in the form of a curved piece of wire. At the place of the fold, it has a rounded formation called an ear.

The ends of the wire of the product are straight, the upper one is slightly shorter than the lower one, they adhere tightly to each other. Such cotter pins are unreliable, they are used mainly once, since they are made of soft metal and cannot withstand cyclic use. Simply put, they break. For a more reliable fastening of mechanism parts, an improved version of cotter pins is used - spring.

Feature and purpose

The difference between spring devices and other locking elements, such as a locknut, is that the fastening of the cotter pins does not loosen over time, even in the presence of strong vibration. The hardware product has a low cost and can be used repeatedly. The direct purpose of the spring cotter pin is to ensure safe fastening of the part, as it were, control fixation.

The fastening and locking of the part is quick, easy, the device can be changed for a new one and is convenient to use. The cotter pin itself is a cheap fastening tool, which makes it convenient when replacing.

The standard or turnover (spring cotter pin) lug is used to attach any structure, such as connecting links. This element is designed to provide speed and maneuverability during operation.

In the spring version, there is a significant difference from the standard sample - additional fastening strength due to the action of the spring. The cotter pin is an elastic product for quick installation, insertion into the part for locking, for example, to prevent self-loosening of nuts and bolts: during operation and vibration, you can lose the part and harm the entire process of the mechanism. The size of the mount directly depends on the diameter of the part. If the dimensions do not match, it will be impossible to fix. Sometimes you have to drill a hole in the mounting screw to install the cotter pin.

Varieties

The needle cotter pin is used to connect and fix detachable structures, provides quick assembly and disassembly of component parts. The upper end is made in a zigzag pattern, reminiscent of the letter R. This feature makes it possible for the upper part of the leg to grip the part from the outside: it is automatically snapped in several places at once. And the straight part, introduced into the hole, remains fixed, motionless. Thus, there is a double-sided fastening of the pin, nut or bolt.

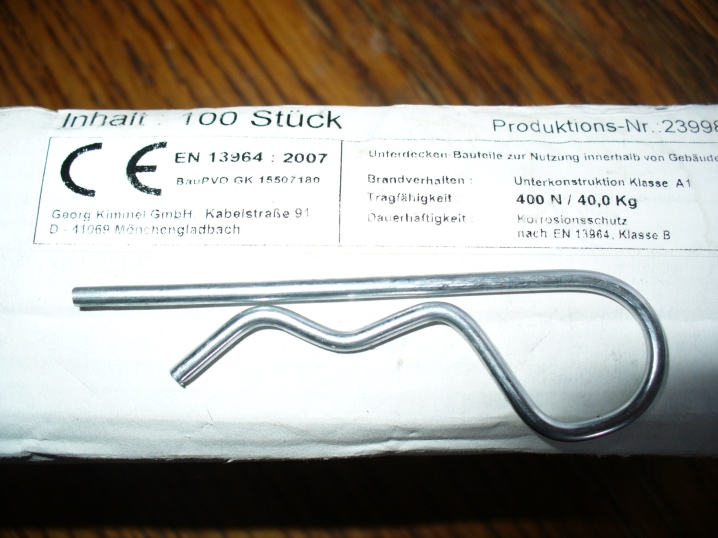

The product can be made of various types of steel, with or without a corrosion-protective coating, which affects the long-term use and the price of the cotter pin.

A quick-release cotter pin with a ring (cotter pin) has a fixed rod that is inserted into the screw hole. The attached ring with free movement is thrown over the end of the fastening element from above for additional fixation, it is a folding plug. Unlike previous types, this mount has a great advantage, as it is used many times.This is an important factor when assembling and disassembling structures for instant fastening. The convenience of just this shape, reminiscent of a check, is that when removing the cotter pin, you just need to raise the ring and, pulling on it, pull out the cotter pin.

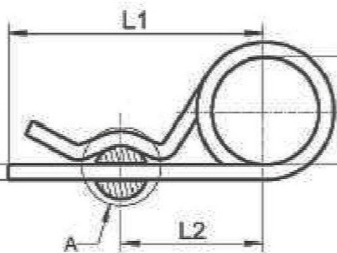

The spring cotter pin is a little more complicated in design, there are two types: with a double loop in place of the lug and a single one. The double reversible eye is springy during operation, providing additional reliability and maneuverability in fastening parts. The upper end is made in a zigzag pattern.

The straight part is inserted into the hole, there is a double-sided fastening of the pin, nut or bolt.

Standards

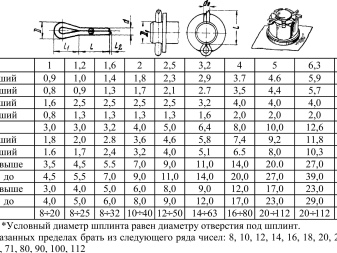

According to GOST No. 397-79, the types of cotter pins are divided into subgroups by numbers.

DIN 11024 - spring (needle), diameter from 2.0 to 8.0 mm, length from 50 to 110 mm, hole diameter from 2.5 to 9.0 mm.

DIN 11023 - quick-detachable with a ring, the diameter of the immersion rod is from 4.5 mm to 11 mm, the length is from 32 to 40 mm, the diameter of the ring is 41 mm, the length of immersion in the fastener is 37 mm.

Various metals can be used in the production of cotter pins, the most reliable is hardened steel.

Applications

The simple design of the spring cotter pins allows them to be used in many industries. They are used in aviation, mechanical engineering and shipbuilding. Due to their high reliability and uncomplicated design, cotter pins are used everywhere. For example, when connecting lever systems, in the manufacture of belts for lifting mechanisms. However, the lateral impact on the cotter pin should not be high: its structure is unreliable. For this, steel pins are used, since they can withstand high mechanical loads.

Unlike connecting threaded parts, cotter pins are a more rational solution, they even serve as a backup fastener for threaded ones, provided there is a hole for the cotter pin. You can use the mounts even in handicrafts at home. Some compounds in the manufacture of toys are made precisely with their use.

How to make a spring cotter pin with your own hands, see below.

The comment was sent successfully.