Features and types of stainless wire

Knowledge of the features and types of stainless wire is a must for any experienced technician and home craftsman. It will also be useful for people seeking to broaden their horizons. There are many varieties of such a product, and one should not confuse their areas of application.

Classification

Modern stainless steel wire is not just made of steel with a minimum level of corrosion. It is also always a high-level alloyed material that is resistant to strong heat. The universal long construction is easy to recognize - it looks like a thread or a string. The predominantly stainless wire has a circular cross-section. It is used in a wide variety of areas, therefore it is represented by a number of modifications.

Knitting wire is very popular. It is used to secure fittings - and it is not surprising that this material should not rust for as long as possible during normal use. The main requirements are stated in GOST 3282-74. Experts have long noted that the thicker the reinforcement, the larger the section of the wire used should be. It should be positioned as evenly as possible, because otherwise the loads will be distributed incorrectly.

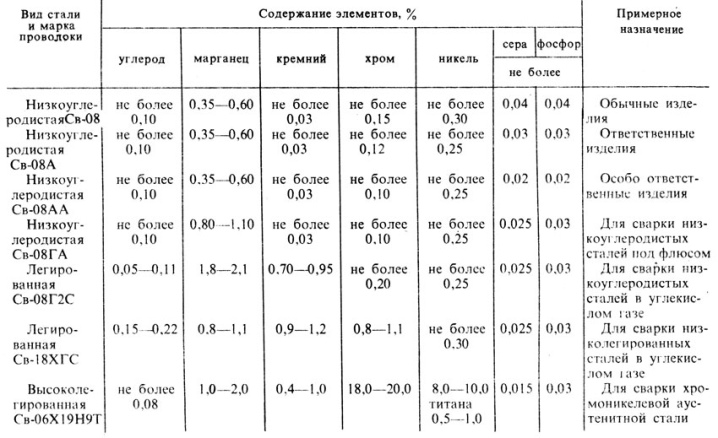

But welding wire can also be stainless. This material is valuable because the finished weld also has excellent anti-corrosion properties. Basically, special steel fibers are used for fully or partially automated welding processes. It is useful both for work in an inert gas atmosphere and for welding powdered metal.

It is worth considering that such a wire also serves as a blank for obtaining full-fledged electrodes.

Work-hardened wire deserves special attention. It is needed to:

make brushes for manual cleaning and various cleaning machines;

to produce metal fiber (one of the types of reinforcement for concrete);

make cables and ropes;

receive simple springs;

perform parts for cars and trucks;

form fences and other enclosing structures.

Stainless steel spring wire is made of steel with a high carbon content. It is used when it is necessary to make especially complex and important springs. The section of the metal thread can be in the form of a circle, oval or rectangle - depending on what is needed in a particular case. The fiber diameter is 0.3 to 5 mm. If alloy steel is used, the largest diameter is increased to 8 mm.

It is customary to highlight the following types:

hot rolling products;

cold rolling products;

light metal (free from oxides);

oxidized products;

copper-plated wire;

products of normal and increased accuracy;

wire of 1 and 2 categories of ductility.

Marking

The designations of steel wire according to GOST 1972 are as follows:

X - cold rolled products;

T - heat treatment (including products of the oxidized type with signs of tarnishing);

TC - a light metal that does not contain oxides and is devoid of signs of tarnishing;

P - increased manufacturing accuracy.

The weight (mass) of a stainless steel wire of circular cross-section with a length of 100 m is taken as follows (depending on the diameter):

0.5 mm - 0.31 kg;

1 mm - 0.62 kg;

1.5 mm - 1.4 kg;

2 mm - 2, 48 kg;

2.5 mm - 3.88 kg;

3 mm - 5.58 kg;

4 mm - 9.93 kg;

6 mm - 22.3 or 22.6 kg.

The smallest possible diameter is 0.3 mm. But finding such a wire is quite difficult. Most often abroad they use metal wire of the AISI 321 category.In domestic practice, its close analogues are 08X18H10T or 12X18H10T. Cold rolled products can be from 0.51 to 1.01 mm in diameter, and hot worked from 0.3 to 6 mm. When marking steels, those substances that are less than 1% are allowed not to be indicated. Alloy 12X18H10T stands for:

no more than 0.12% carbon;

up to 1% titanium;

exactly 18% chromium;

exactly 10% nickel;

everything else is iron.

Despite being chemically inert, stainless wire deserves careful handling. Its diameter is wound on spools or packed in skeins.

For cover from mechanical stress, a film or standard wrapping paper is used. It is highly recommended to transport the wire in a closed transport protected from rain. Its storage is allowed only in heated rooms.

In this case, you will additionally have to protect the material from water. The length of the winding or coil is determined by the customers themselves. The wire must be wound in the form of strictly regular clear rows. Otherwise, it will be very difficult to rewind the required amount of material. The storage period (subject to the established rules) is not limited.

Areas of use

Stainless wire is used very widely. As already mentioned, ropes and springs are made from it. It also serves as a raw material for a variety of mechanical parts. Wire with stainless properties is actively used in:

engineering industry;

medicine;

energy;

construction;

transport industry.

Stainless steel is excellent for a wide variety of welding jobs. The wire obtained from it has a matte surface and is not covered with any coatings. Most often, such products are obtained on the basis of the Sv-04Kh19N9 and 06Kh19N9T alloys. The high degree of alloying makes it possible to achieve extremely solid qualities.

But also the metal of the Sv-12X11NMF and Sv-10X17T grades is now getting quite widespread.

These two alloys contain over 10% alloying additions. The stability of the stainless material at high temperatures and exposure to various substances allows it to be used with confidence in the production of important parts and electrical equipment. The oil industry also cannot live without wire - they make equipment for pumping towers from it. Of course, oil production and refining require the use of wire for welding as well. It is also widely used in the furniture industry.

A quality wire material can last for many years with skillful use. He is almost not afraid of loads and in this regard he shows himself as worthy as plates, sheets, plates and profiles.

But the role of stainless wire is especially great in the food industry. Corrosion resistant steel has long been recognized as one of the most suitable materials for food handling equipment. The material is hygienic, chemically inert, relatively cheap and readily available.

The same properties determine the widespread use of stainless steel wire in the chemical industry. Because of them, it is readily used in the production of surgical instruments and precision medical equipment. Manufacturers of building materials are interested in stainless wire mainly as a raw material for making a welded seam. But it can also be used as an auxiliary component for reinforcement. Another wire made of improved metal is needed to weld the same stainless steel.

It can be used in a fairly aggressive environment. Therefore, this material is appreciated by manufacturers of aircraft, river and sea vessels. On them, it is used wherever you need the most stable and at the same time very accurate connections. Stainless wire is interesting, however, also to car manufacturers. A lot of braids, springs and cables are made from it, because it is difficult to find another workpiece with greater resistance to mechanical stress at the same price.

See below for more details.

The comment was sent successfully.