Features of flux cored wire

The procedure for welding steel structures using electrodes is not always convenient. Difficulties in carrying out this process are observed in an open area, at a height.

In order to avoid the formation of low-quality seams, some craftsmen use a cored wire.

What it is?

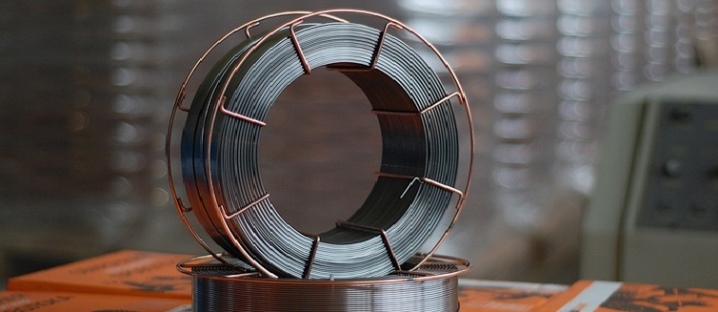

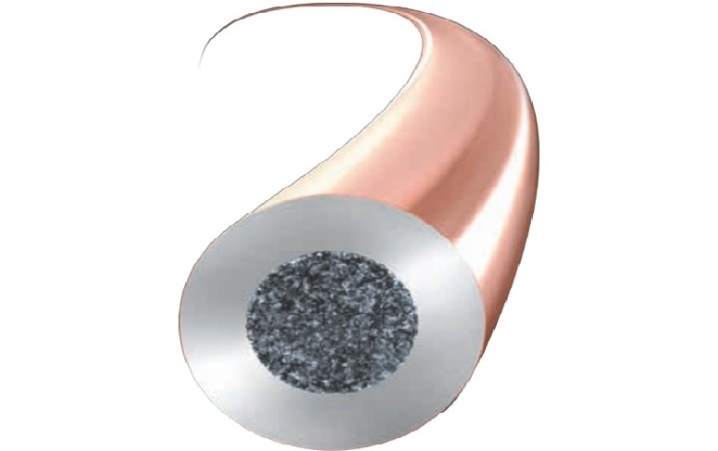

Welding wire is considered an important part of most modern welding technologies. The powder attribute has the form of a hollow metal tube, inside which a flux is located or it is also in combination with a metal powder. This wire is used to create welds in semi-automatic gasless welding. Thanks to the modern appearance of this attribute, an easy ignition of the arc is carried out, as well as a stable combustion process.

The production of flux-cored wire is based on strict adherence to GOST, therefore, its use provides a high-quality result. The presence of a fine fraction of iron, phosphorus, chromium inside the tube guarantees the following points:

- stabilization of the temperature in the area of the bath, as well as around the arc, until it becomes suitable for the material used;

- stimulation of mixing of the fused metal on the parts, as well as the electrode;

- uniform closure of the seam across the entire width from contact with gas;

- ensuring the uniformity of boiling and the absence of splashes;

- increasing the speed of welding parts.

With the help of flux-cored wires, surfacing on parts is carried out, as well as the welding procedure in any place, subject to the availability of special equipment. Given its intended use, the tube may contain magnesite or fluorspar. If it is necessary to process refractory material, it is worth using wire, where graphite and aluminum are present, as they increase the temperature.

The disadvantages of this type of welding material are the high cost, narrow specialization, the complexity of welding sheets thicker than one and a half millimeters.

Primary requirements

Flux cored (flux) welding wire is used for semi-automatic welding without gas, and it has a tubular appearance. The inner cavity of the attribute is filled with pollen of a special composition. The base is a polarized metal strip. The final stage of creating such a wire is to gently stretch it to the required dimensions.

Any type of flux cored wire must meet the following requirements:

- melt evenly and avoid excessive splashing;

- be characterized by stability and ease in the occurrence of an electric arc;

- slag arising during the welding process must be distributed evenly and not penetrate into the seams;

- have an even seam without the presence of cracks, pores.

Comparison with conventional wire

Welding wire is divided into several types, the most common of which can be called powder and solid. Despite some differences, both attributes are used quite frequently. The solid type of wire has a copper coating, and it can also be used with inert gases, which cannot be said about the second type of welding attribute.

In addition, the manufacture of flux-cored wire is a rolling of a strip of metal, rolling it with a ribbon with the addition of flux.

Solid wire has a lower cost, but it lacks some of the advantages of flux cored, such as:

- use for vertical uphill welding;

- work with galvanized steel and other difficult-to-weld varieties;

- the inability to add various substances inside the wire.

Species overview

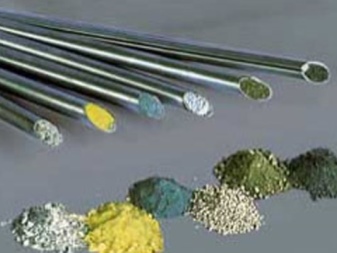

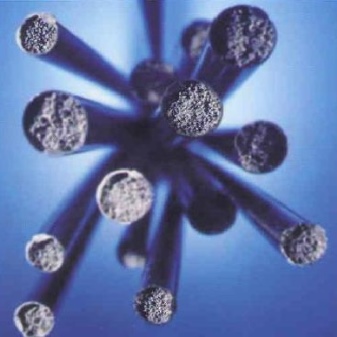

Every welder should know that today there are several grades of flux-cored wire that can be used for thermal spraying, electric arc metallization, alloy steel and many other purposes. Judging by the characteristics of the varieties of this welding attribute, each product has a certain diameter, marking, materials for the shell, as well as aluminum, iron or other filling.

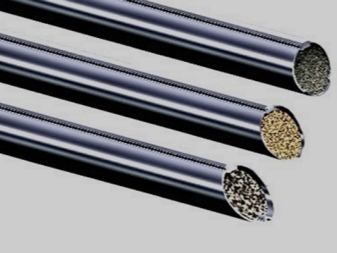

Metal tubes are divided in shape into round ones, at which the edges are butt-connected, with key bends, and also multilayer.

According to the peculiarities of use, powder attributes are divided into such varieties.

Gas protection

This type of wire requires a closure over the weld pool. For this purpose, argon or other inert gas is used. The gas shielding attribute for welding is usually used for welding carbon, low alloy steel. This wire has the following advantages:

- arc stability;

- ease of slag coming out to the surface;

- lack of porosity;

- low level of spraying;

- simplicity of slag liquidation.

Deep penetration is inherent in such pipes. Their use is in demand when creating joints at joints and corners, as well as overlaps during the manufacture of structures and pipes from metal.

Self-protective

The self-shielding tube is a good option for semi-automatic operation in any space, even in the field. This welding attribute does not need the presence of additional types of consumables. While working on the bathroom, a cloud accumulation from the gas charge is noticed. As a result of the use of self-shielding wire, an even flux is applied to the seams, while it hides the hot joints with a wide strip. This type of flux-cored wire has found its application during welding of materials in unequipped conditions. With its help, aluminum products are soldered, as well as their alloys.

The powders that are concentrated in the filler wire can perform the following functions:

- alloying;

- deoxidation;

- stabilization of the electric arc;

- simplification of the formation of the uniformity of the seams.

Depending on the composition of the powder, the self-shielded wire can be:

- fluorite;

- fluorite-carbonate;

- rutile;

- rutile fluorite;

- rutile organic.

Features of use

The use of a semiautomatic device during welding contributes to the rapid application of seams, because the powder type of products is fed without interruption. Since a gas hose may not always be available for work, this method allows you to weld metals in a shielding gas environment. Practically everyone will be able to cook correctly without gas, while special attention should be paid to surfacing and setting. In mechanized welding, it is imperative to take into account the current parameters, polarity, as well as the correct execution technique.

There are nuances in working with this metal device that the master should not forget about. In order to successfully lead the arc and form a seam, it is worth preparing a flat surface. When working with semiautomatic devices, this can be achieved by switching contacts in the interior of the unit.

The wire that goes to the burner must be connected to the ground cable, and the opposite wire must be switched to the burner terminal.

An important point in the work is the installation of rollers that fully correspond to the diameter of the wire used. On the side of the roller there is information about the diameter range. A roller with a movable type should not be tightened tightly, since the wire is characterized by a hollow structure, and this event may lead to its deformation or the occurrence of a blockage in the cable channel.

For in order for the wire to run smoothly, you will need to remove the tip located at the outlet of the clamping element. Its winding is carried out after the consumable element appears from the end of this channel. The diameter of the tip must also be matched to the size of the wire, as a large hole can make it difficult to control the arc. No gas is used during this procedure, so it is not necessary to put on the nozzle. In order for the spray not to stick to the tip, it should be sprayed with a specially designed product.

When welding with flux-cored wire material, the seam will always be under review, so the technology will externally resemble the standard use of electrodes.

Since the powder attribute of welding does not have mechanical strength and rigidity, experts recommend using a special mechanism, which ensures the continuity of the automatic feeding of the element.

In the process of welding, there is an intensive formation of slag, it must be quickly eliminated with a metal brush. Otherwise, slag can get into the working area, which will lead to the formation of defects and a decrease in mechanical strength.

Flux-cored wire can be made entirely of metal or be flux-filled, thereby fulfilling the tasks of a gas. Using this weld attribute may result in a lower quality weld than usual, but in some cases it is impossible to do without a powder additive.

Transportation of gas cylinders is not always appropriate, so the technician can use flux-cored wire, for example, at a height or in an inconvenient place. As practice shows, for home use with a small amount of work, this welding option is expensive. But in production, when using powder tubes, fast and high-quality welding can be carried out even by inexperienced specialists. It was also noticed that such welding can pay off when applying a long seam, otherwise a lot of waste is obtained.

Flux-cored wire welding is described in the following video.

The comment was sent successfully.