All about bee frame wire

Beekeeping is a fascinating and profitable activity, and bee honey is a unique product, tasty and healthy. Without exception, everyone knows that honey in a hive is in combs, but not everyone knows that these combs can weigh up to five kilograms. Wooden frames reinforced with thin strong wire keep this weight. The features of the materials for stretching the frames, the methods of stretching them, will be discussed in this article.

Peculiarities

A special wire is pulled over the bee frame, on which the foundation will be attached in the future. Such material can have a different composition and thickness. They differ both in material and in characteristics.

The wire must meet certain requirements:

- it must be especially durable;

- have high resistance to corrosion;

- have the ability to resist stretching, which means sagging when the temperature rises;

- be suitable for food use.

The peculiarities of this material include the fact that it is recommended to stretch such a wire at temperatures above 20 degrees, otherwise it may sag in the future.

Purpose and device

The main purpose of the wire is reinforcement. It serves to strengthen and provide additional strength of the honeycomb, and also creates a support for the sheets of foundation when nesting beekeeping nest frames. The process of waxing is complex and time-consuming, requiring the use of special devices, devices and tools.

For small amateur apiaries, it is enough to use the simplest tools:

- wooden frame;

- wire;

- awl - for piercing holes in the side strips of bee frames;

- pliers - they fix the ends of the wire;

- carnations - directly serve as clamps;

- hammer - for hammering them.

To avoid cuts while working, it is worth using special fingerless gloves.

It should be noted that large apiaries require the use of special tools and devices.

Views

The wire used for bee frames comes in many different types. This material may vary in weight, composition.

Typically, bee frame wire is sold in spools. Coil size and weight may vary:

- for large ones - up to several tens of kilograms;

- small or standard ones - from 500 to 400 and even 250 grams.

Many beekeepers, trying to save money, purchase large rolls, and then rewind them into smaller rolls.

The beekeeper should know that buying large coils or purchasing small coils in bulk will cost him less (sometimes half the price).

By material

Wire made of different materials can be used to stretch the bee frames.

- Stainless steel products. The most common use of this particular option. It is offered to beekeepers by domestic and foreign manufacturers. The difference lies not so much in quality as in the price of the product. For example, products from India or China are often cheaper. Stainless steel serves for a long time. It is suitable for food use and does not oxidize.

- Fechral wire. It is made from an alloy of a number of metals and, which is important, is cheaper than stainless steel, while surpassing it in a number of indicators. Beekeepers have only positive reviews about this wire.

- Nichrome wire. It is a quality material with good characteristics.It costs more than other options, and it is not always easy to find it.

- The cheapest, but also less quality, is iron (or black) wire. It is not resistant to erosion, does not last long, stains hands, and often honey.

The choice of material depends on the personal preference of the beekeeper. The price and availability of products play an important role here.

By characteristics

When choosing a skein, you need to pay attention to its diameter. Often the tensile strength depends on the thickness. First of all, this applies to stainless steel. Its thickness should not be less than 0.5 mm. The domestic industry produces these products with a diameter of 0.56 mm. Stainless steel from India and China, as a rule, is produced in diameters of 0.5 mm, 0.4 mm, 0.33 mm.

Nichrome wire also has high tensile strength. Its diameter can be 0.37 mm. Such a thickness allows for a more accurate naschivanie frames, and bees on such a foundation quickly build up the honeycomb.

Fechral products also do not stretch, which allows using a small diameter for pulling the frames.

But the iron should be thick - at least 0.55 mm in diameter, because it is most susceptible to stretching.

Tensioning methods

Currently, there are different options for stretching the bee frames. The most often used option is with four rows, less often - five or three. There is also a zigzag stretch, W-shaped.

In amateur apiaries, where there is a small amount of bee frames, the wire can be pulled even on the knees. Many beekeepers carry out this kind of work with an awl, piercing holes in the side strips of bee frames. In this case, the wire is inserted into the holes, as a rule, in four rows, and its end is fixed by the upper stud.

Then, using pliers, it is tensioned, and then fixed by the lower nail.

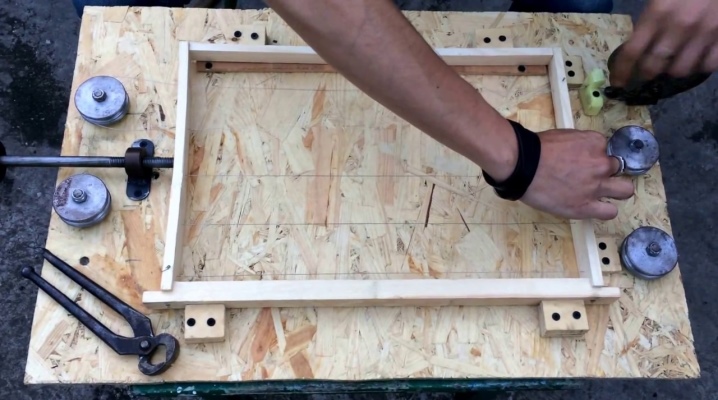

With large volumes of work, there is a need for mechanization, which will speed up the assembly of the frames themselves and the tension of the wire. So, instead of a hammer, it is recommended to use a stapler. A simple device - the hole punch will speed up the punching - of the wire holes in the side strips of the frame. In addition, such a device makes the distance between the holes the same. A special machine will help to tighten the frames faster, and the tension on it will be of better quality.

For information on how to make a bee frame with your own hands, see the next video.

The comment was sent successfully.