All about the weight of professional sheets

Despite the small thickness - about 0.7-1 mm - the profiled sheet has a significant weight. One person cannot take it away, and not only because of the sharp edges that make it difficult to take it even with mittens.

What does it depend on?

The density of iron is approximately equal to 7874 g / dm3. The steel from which the profiled sheets are made fluctuates in this indicator within the range of 7.7-7.9 kg / dm3. Profiled sheet - pressed steel sheet, in which the required profile is extruded with the help of a press. Most often this profile is trapezoidal. Small amendments to the weight of the profiled sheet are made by galvanizing and painting.

If with a zinc coating, the calculation of the weight of the profiled sheet is simplified - the thickness of zinc in microns on all profiled sheets is the same - that cannot be said about organic coatings. Zinc, not afraid of rain and snow in general, is corroded by the weakest acids, salts and alkalis contained in rain in urban conditions, as well as in bird droppings. For this, a layer of paint is applied.

The polymer is sprayed in two layers, sometimes sheets with a double-sided coating come across, its advantage is relative strength. Acrylic is protected from ultraviolet radiation - it does not fade after a year or two, and also easily withstands 25 years of trouble-free service near the seashore in salty rains. PVC coating is not resistant to elevated temperatures: it quickly collapses in the scorching heat. Pural, unlike PVC, will withstand temperature fluctuations from -25 to + 100 ° C. Polyvinylidene fluoride is resistant to UV and in arctic frost conditions - up to -60, while combining most of the advantages inherent in previous types of coatings.

Finally, the weight of the profiled sheet depends on its real area. Regardless of how the manufacturer bent the profiled sheets on the press machine, it is important to consider what is the area of the typical source from which the profiled sheet is bent. The seller indicates the real area of the already bent profiled sheet, and not its direct analogue-source - it is important for the buyer to know how many profiled sheets are required to cover a roof of a certain diameter, plus a margin for overlaps of up to 15%.

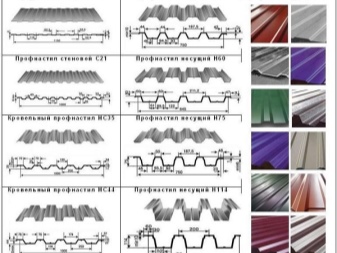

A lot of different types of corrugated board

The area of the profiled sheet is measured in square meters. When ordering and delivery, they take into account how many kilograms per square meter a particular brand of profiled sheet weighs. According to GOST, a consumer who is well versed in rolling building materials, as well as a distributor from whom he acquires a batch of corrugated board of a certain brand, takes this into account, based on the table values of the tolerance of the mass of one copy of sheet steel. As an example, the most common brands are:

- C21 has a thickness of 0.5-0.72 mm, the mass of 1 m2 is 5.8-7.5 kg and a width of 125 cm;

- C44 has a weight of 1 m2 in 7.4-8.4 kg - with a product thickness of 0.72-0.83 mm, width - 125 cm;

- The H60, with a thickness of 0.7-0.93 mm and a width of 125 cm, weighs 8.8-11.1 kg / m2;

- H75 with a thickness of 0.7-0.91 mm weighs 9.8-12.5 kg, the strip is still the same 125 cm.

The characteristics of SN profiled sheets have a wider range of values.

Wall

The weight of the profiled sheet does not exceed several tens of kilograms.

|

Brand |

Thickness, mm |

Width, cm |

Weight of 1 m of length or 1 m2 of area, kg |

|

S-21 |

0,5 |

100 |

5,4 |

|

0,55 |

5,9 |

||

|

0,7 |

7,4 |

||

|

S-10 |

0,5 |

4,77 |

|

|

0,55 |

5,21 |

||

|

0,7 |

6,5 |

||

|

S-8 |

0,5 |

115 |

5,4/4,7 |

|

0,55 |

5,9/5,13 |

||

|

0,7 |

7,4/6,43 |

The area of application of the wall profiled sheet is mainly facade cladding, fencing off the sections of utility blocks with partitions. When used as a roof covering, the rafter system tilts at a noticeably large angle.The wall profiled sheet is of little use for pitched roofs due to the small angle of inclination of the roof - its excessive flexibility is compensated for with the help of a lathing with a small gap between adjacent rungs.

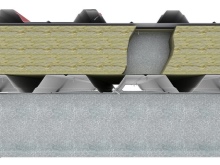

In case of insufficient insulation, for example, mineral wool is mounted under the metal flooring. White or galvanized sheet is used for the manufacture of corrugated ceiling covering.

So, profiled sheet S-10 with a thickness of 0.7 mm, made in the form of a six-meter segment, weighs 39 kg. Half of it - 3 meters tall - weighs 19.5 kg. Linear meter of the product - 1 sq. m bent sheet, completely ready for stacking.

Carriers

The bearing profiled sheet has additional stiffening ribs. It is used for walls of hangars and warehouses, whose construction is made mainly of steel structures. Its use as a roof will enable builders to erect lightweight truss structures - without lathing, with a rafter span of up to 1 m - this will reduce the cost of purchased wood.

The thicker the profiled sheet, the greater the load it will withstand.

|

Brand |

Thickness, mm |

Width, cm |

Weight of 1 m of length / 1 m2 of area, kg |

|

N-114 |

0,8 |

60 |

8,4/14 |

|

0,9 |

9,3/15,5 |

||

|

1 |

10,3/17,17 |

||

|

N-75 |

0,7 |

75 |

7,4/9,87 |

|

0,8 |

8,4/11,2 |

||

|

0,9 |

9,3/12,4 |

||

|

N-60 |

0,7 |

84,5 |

7,4/8,76 |

|

0,8 |

8,4/9,94 |

||

|

0,9 |

9,3/11,01 |

||

|

N-57 |

0,7 |

75 |

6,5/8,67 |

|

0,8 |

7,49,87 |

The second area of use of such a profiled sheet is a fence. Profiled sheets H35 are poorly distributed due to the low wave height, small thickness - they are used mainly for non-capital structures, for example, gazebos and small utility rooms. The larger the wave, the easier it is to lay the profiled sheet - the docking is performed faster and more efficiently.

For example, the weight of the H114 with a length of 2 m is 20.6 kg. For a 4-meter length, respectively, the weight of the H114 will reach 41.2 kg.

Universal

The universal profiled sheet is equally good for the construction of a roof and a fence, as well as for facade cladding. It is used as a wall - for partitions of premises created within the same capital warehouse or garage building.

|

Brand |

Thickness, mm |

Width, cm |

Weight of 1 m of length or 1 m2 of area, kg |

|

NS-44 |

0,5 |

100 |

5,4 |

|

0,55 |

5,9 |

||

|

0,7 |

7,4 |

||

|

NS-35 |

0,5 |

5,4 |

|

|

0,55 |

5,9 |

||

|

0,7 |

7,4 |

For example, the mass of a 5-meter HC35 with a thickness of 0.7 mm reaches 37 kg. A professional sheet is a material that cannot be bought by the piece, taking it on yourself - with the exception of only the shortest, thin-walled and lightest specimens.

A thin-walled sheet has another drawback - it is easy to wrinkle during long-term transportation, so the boards are transported on wooden stands in batches.

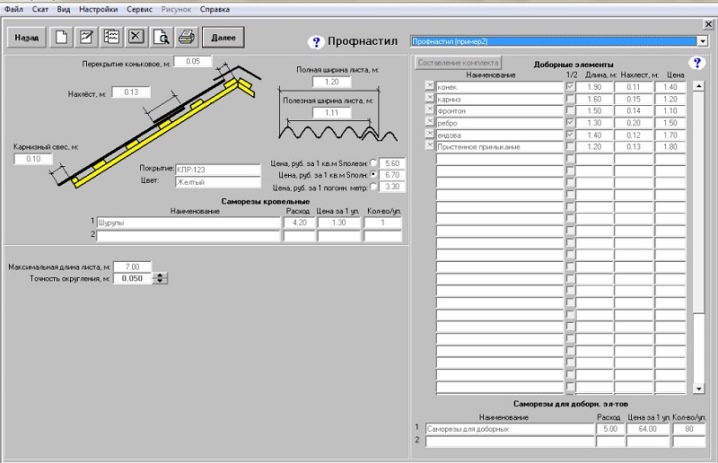

How to calculate?

The calculation of the profiled sheet by weight is carried out by the specialists of the distribution companies. In addition to online calculators, which have all the data for calculating the mass of the ordered batch, the calculation is made by the user himself. The mass of a square meter taken from the table is multiplied by the length - that, in turn, varies within 5-12 m. Steel rolling mills do not produce longer profiled sheets - there is no need for this: consumers calculate the number of sheets on their own and choose the required standard size, focusing on including the cost. Tabular values are indicated for practical (working), not absolute sheet area.

Calculation of the weight of the profiled sheet can be complicated - most of the sheets have not only a zinc coating, but they must be painted with a polymer protective layer. To protect against moisture, polyurethane and plastisol are used - knowing the composition and density of these components, it remains only to calculate the real (absolute) area of the painted profiled sheets, taking into account the dimensions of the trapezoidal wave. But such a calculation is only for an amateur - the overwhelming majority of customers are guided by ready-made values determined by the corresponding GOSTs, in which the specific weight of the profiled sheet is clearly indicated, depending on its thickness and working (installation) area.

The comment was sent successfully.