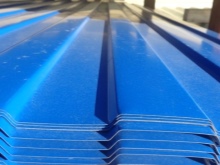

Everything you need to know about C21 professional sheets

This article will focus on one of the most versatile modern materials. At the moment, it is widely used in the performance of both roofing and facade, and general construction work. Consider further everything you need to know about C21 professional sheets.

Description

The key feature of the profiled sheet in question is the height of the trapezoid (wave), which is 21 mm, which provides an increased bearing capacity. In addition, the list of clear advantages includes affordable cost, practicality, durability and profitability. Taking into account the main parameters, galvanized corrugated board is actively and successfully used in the construction of structures exposed to significant wind loads.

Long-term practice has proved that profiled sheet made of rolled steel is a high-quality and easy-to-use building material. Now such panels are widely used primarily due to their versatility. Do not take off the aesthetic side as well, since the corrugated board looks good. Due to the fact that it is durable and lightweight, various structures are quickly erected from it.

We are talking, for example, about small outbuildings, fences, gates and, of course, roofs.

Many are interested in what is the difference between C21 and C20 grade sheets. To answer this question, it is necessary to initially highlight the key characteristics of the material in question.

- A variety of colors for C21 profiled sheets with a polymer protective layer. Simple galvanized panels (without coating) look no less attractive.

- Affordable cost. So, the price for 1 sq. m starts at 150 rubles.

- Relatively low weight, due to which installation and transportation of sheets is maximally facilitated. This allows you to perform most of the work, regardless of their complexity, by two, and sometimes even one person.

- Long service life of the material. In practice, the profiled sheeting retains its basic qualities for up to 30 years. The aesthetic component is no less important, since the structures maintain their appearance for a long time. It is noteworthy that this is relevant for difficult operating conditions.

- Versatility, providing the possibility of widespread use, as well as combining with different materials made of metal, wood and plastic.

- The presence of the most resistant to damage and the effect of an aggressive environment of a protective layer on the surface. This refers to sheets with a polymer coating, which almost completely prevents corrosion.

- A wide range presented on the market by many companies specializing in the production of sheet building and finishing materials.

Analyzing the differences between C21 and C20 corrugated board, it should be noted that both options have an identical scope. This refers to both the creation of a roof and the construction of walls.

Both brands are successfully used in private and industrial construction. Both types of material can be simply galvanized, and also have an additional protective layer of polymers. In principle, the basic characteristics of these profiled sheets are the same. The most significant difference lies in the length of the panel (the C21 is large).This means that the material's ability to withstand increased loads is improved. But at the same time, the cost of the profiled sheet is also increasing.

How do they do it?

To date, the described professional sheet is produced by many metalworking enterprises. This is due to the simplicity of the production process and the absence of the need for expensive equipment. But it is important to consider that the release of this sheet material is regulated by several official documents.

- GOST R52246-2004, in accordance with which the galvanized profiled sheet must be made of cold-rolled, coiled steel (grade 220-350 or 01). An important point in this is the availability of appropriate coverage.

- GOST 24045-94, taking into account the norms of which the production of ordinary profiled sheets is carried out.

- GOST R52146-2003, setting the standards for the production of painted C21 from galvanized galvanized with a polymer surface.

An important feature is that bare cold-rolled steel is rarely used as a raw material for production. This is due to the short service life of the material, which does not have anti-corrosion protection. As a rule, such sheets will last no more than 5 years. The situation changes dramatically due to the application of a zinc layer or the creation of an aluzinc coating.

By the way, the use of this technology does not significantly affect the final cost of production. As a result, the service life can be extended to 25-30 years.

In addition to everything already listed, it is worth paying attention to the use of a polymer coating. Polyester, pural, polyurethane or plastisol is applied in a thin layer to the surface of cold rolled steel blanks. The next stage of production is heat treatment of the material in ovens. In the process of melting the polymer, a strong film is created. One of its key characteristics is maximum elasticity, due to which the created protective layer is not damaged during rolling.

The list of advantages of the polymer coating:

- double protection against corrosion;

- service life reaching 30-50 years;

- aesthetics that allows you to embody different design ideas;

- resistance to the negative effects of aggressive environments, including direct sunlight and sharp temperature fluctuations.

Thanks to the introduction of the described technology, the production of profiled sheets is carried out, which can be dismantled and reused at other facilities.

Species overview

C21 corrugated board, presented by the leading manufacturers of the industry in the corresponding segment of the building materials market, is made of high-quality steel. At the same time, options with galvanizing, special paint and protective coatings are available to the consumer. It is with this parameter in mind that profiled sheets are divided into two main categories. Each of them has its own characteristics in terms of performance.

Unpainted

In this case, we are talking about the simplest version of the production of profiled sheet material. Steel of the corresponding quality with applied zinc coating is used as blanks. This layer is designed to protect the panels from corrosion. Due to the absence of colored and polymer layers on the surface of the profiled sheets, affordable cost will be a key competitive advantage.

Painted

This type of products used in roofing and other works has certain features. Colored and protective coating can be applied on one or two sides. In addition to improving key performance indicators, the use of technology can significantly expand the range of products offered. As a result, the consumer can choose almost any color.

Dimensions and specifications

The working (excluding the longitudinal assembly overlap) and the total width of the panels are 1000 and 1051 mm, respectively. At the same time, manufacturers offer sheets of different lengths on the market. As a rule, companies produce products, the specified size of which depends on the wishes of the customer. Most often, the length of the sheets varies in a fairly wide range with a step of 10 cm. The standard indicator is 6 meters. As practice has shown, it is these dimensions that are the most convenient for transportation and most of the work. This is relevant when constructing a roof from corrugated board. The maximum length of the sheets reaches 12 meters.

Knowing the key parameters, you can easily decipher the marking. For example, profiled sheet C21-1000-0.55:

- 21 is the height of the wave, that is, the trapezoid, in millimeters;

- 1000 - working (useful) width in millimeters;

- 0.7 is the thickness of the original steel billet used for the production of sheets.

It maximally simplifies transportation, carrying within the facility and the installation itself, the small weight of the material. For example, when used as roofing panels with a thickness of 0.7 mm, the mass of one "square" of the coating will be 7.4 kg. Another important point is cutting the sheet to length in the range from 1 to 12 meters. Taking into account the rigidity and increased bearing capacity, this allows you to reduce to a minimum the number of joints during installation. This is especially important when performing roofing work.

It is necessary to pay attention to such an important characteristic as the weight of the profiled sheet. The mass of one running meter and one useful "square" depends on the thickness of the material as follows:

- S-21-100-0.4 - 4.45 kg;

- S-21-100-0.4 - 4.9 kg;

- S-21-100-0.5 - 5.4 kg;

- S-21-100-0.55 - 5.9 kg;

- S-21-100-0.6 - 6.4 kg;

- S-21-100-0.65 - 6.9 kg;

- S-21-100-0.7 - 7.4 kg;

- S-21-100-0.8 - 8.4 kg.

In order to correctly determine the weight of the batch when purchasing, it will be necessary to multiply the mass of a running meter by the length of the sheets, as well as by their number. The next parameter is the working width of the C21 profiled sheets. This value is determined by calculating the difference between the full width of the panel and the amount of installation overlap.

By the way, this indicator is also taken into account when calculating the area of \ u200b \ u200bthe created coating and the required material.

Nuances of choice

Before purchasing any building and finishing material, it is recommended that you familiarize yourself with its main properties and characteristics. This will allow you to make the right choice, taking into account specific tasks. C21 professional flooring is no exception. When choosing sheets, it is necessary to consider a number of important points.

- Sheet sizes. When calculating the required number of panels, it is important to take into account the features of the future design. As already noted, the dimensions should be selected taking into account the purpose of using the corrugated board.

- Profile shape. The height of the trapezoid in this case is 21 mm, which can be understood from the marking. It should be noted that due to such dimensions and shape, the longitudinal overlap is minimized during installation. As a result, it is much easier to fasten the sheets, and the process itself is significantly accelerated and involves the use of minimal resources.

- The thickness of the sheet, on which the cost of the material directly depends. On the one hand, the thicker the sheet material, the more expensive it will cost to the buyer. At the same time, it is this parameter that will determine such important performance indicators as strength, reliability, resistance to external influences and service life.

- The weight of the corrugated board is C21. This characteristic must be taken into account even at the preparatory stage of performing any work. This is especially true when calculating the rafter system of the future roof. At the same time, when erecting a wall structure, fences and barriers, the strength of the structure will largely depend on the correctness of the calculations.

It is also highly recommended to take into account when choosing the type of coverage. At the moment, the following types of profiled sheets are available to a potential buyer:

- with zinc coating, without additional protective layer;

- galvanized panels with a polymer coating on one side;

- galvanized profiled sheets with a durable polymer layer on two surfaces.

Taking into account the operational properties, the third option is the undisputed leader. Its main advantages include maximum service life and high resistance to mechanical and chemical influences. Appearance plays an equally important role. But do not forget that such professional sheets will cost more than simple galvanized ones.

Applications

The described type of corrugated board is one of the most common due to its key characteristics. Such sheets are widely used in modern construction. In other words, they can not only cover roofs or sheathe individual structural elements of buildings. The material is used when performing a large number of construction and finishing works. We list the main areas of application of C21 profiled sheets.

- Construction of roof structures for residential buildings, outbuildings, as well as industrial and other buildings. It is important to consider that the angle of inclination of the roof in this case does not matter.

- Installation of prefabricated buildings and temporary structures. These include warehouses, shopping pavilions, garages and more.

- Creation of small architectural forms.

- Erection of frame structures, including stiffening diaphragms.

- Panel elements for fences and barriers of almost any configuration and complexity.

- Creation of insulated and "cold" wall structures.

- Wall cladding of various rooms and buildings.

In addition to the above, corrugated board is used in the manufacture of high-quality and aesthetic sandwich panels.

Mounting

Before you start laying the profiled sheet when finishing wall structures or installing a roof, you should take care of arranging the lathing. In addition, in the case of roofing work, you will also need passages and a ridge seal.

It is also important to pay attention to the requirements for the panel mounting scheme and the number of screws per 1 m2. Of particular importance will be the prevention of the formation of condensation, which inevitably appears with the improper use of finishing materials made of metal.

It will be best to consider the features of installation using the example of arranging the roof. This process has some peculiarities.

- The pitch and thickness of the sheathing boards are determined by the bearing capacity of the roofing material, that is, the corrugated board. And also the list of important factors includes potential loads on the coating, the angle of inclination of the roof slopes and the distance between the elements of the rafter system. Correct stacking of sheets provides for a lathing step of 30 cm with a tilt of 15 degrees. The recommended section of the boards is 30x100 mm. It is important to remember that this parameter will depend on the step of the rafters.

- If the slope has a rectangular shape, then the fastening of the sheets can be started from any end of the roof. In situations when it comes to other geometric shapes, it is worthwhile to first make the necessary calculations by displaying the diagram on paper. Directly at the cornice, the sheets are fastened with self-tapping screws with a pitch of 30 to 40 cm.On the next rows, these fasteners are staggered every 100-150 cm.At the gables, the pitch should be 50-60 cm, and in the places of longitudinal joints - from 30 to 50 see 1 sq. m of roofing takes 7-10 screws.

- In accordance with the applied technologies, the device of the cornices provides for a complex of manipulations. This refers to the aesthetic design of the overhang, the installation of gutters, as well as the provision of air flow under the roof.

- Skates can be of different shapes. A prerequisite for this will be the installation of additional elements of the crate directly at the attachment points. It is important to consider that the space under the ridge must be ventilated. On the ridge, the sheet is attached through a trapezoid (wave) with special self-tapping screws 4.8x70 in size.

- When installing profiled sheets at the ends of the roof, it is necessary to make gable overhangs from 5 to 7 cm. The end itself is often sewn up with a wind board. In this case, the plank is mounted over the profile with ridge self-tapping screws with a pitch of 50-60 cm. The overlaps of the wind board elements are fixed at intervals of 5-10 cm.

After completing all installation work, all debris must be carefully removed from the surface. Unfortunately, it is not always possible to avoid the appearance of scratches on the coating, which must be painted over immediately. It is recommended to remove foreign particles and shavings with a water jet or a soft bristled brush. After cleaning the roof slopes, you should also remove all debris from all elements of the drainage system.

An important point will be taking into account the dimensions of the profiled sheets used. So, if their sizes are small, then laying should always start from the bottom row. This applies to both roofing and wall structures.

As practice shows, the most rational would be to purchase, if possible, corrugated board, commensurate with the future coverage. This will not only speed up and simplify installation, but also minimize the number of joints.

The comment was sent successfully.