All about professional sheets C8

C8 profiled sheet is a popular option for finishing external walls of buildings and structures, construction of temporary fences. Galvanized sheets and other types of this material have standard dimensions and weights, and their working width and other characteristics are fully consistent with their intended use. A detailed review will help you learn more about where and how best to use the C8 brand profiled sheet, about the features of its installation.

What it is?

The professional sheet C8 belongs to the category of wall materials, since the letter C is present in its marking. This means that the bearing capacity of the sheets is not too large, and their use is limited only to vertically located structures. The brand is one of the cheapest, it has a minimum trapezoid height. At the same time, there is a difference with other materials, and not always in favor of C8 sheets.

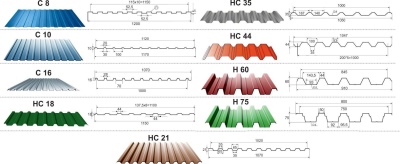

Most often, the profiled sheet is compared with similar coatings. For example, the differences between C8 and C10 brand products are not too great.

At the same time, C8 wins here. The bearing capacities of the materials are practically equal, since the thickness and rigidity of the profiled sheet hardly changes.

If we consider how the C8 brand differs from the C21, the difference will be more striking. Even in the width of the sheets, it will exceed 17 cm. But the ribbing of the C21 material is much higher, the trapezoidal profile is quite high, which provides it with additional rigidity. If we are talking about a fence with a high level of wind loads, about the walls of frame structures, this option will be optimal. When installing a fence between sections with an equal thickness of sheets, C8 will outperform its counterparts by reducing costs and speed of installation.

Specifications

C8 brand profiled sheeting is made in accordance with GOST 24045-94 or GOST 24045-2016, from galvanized steel. By acting on the surface of the sheet by cold rolling, the smooth surface is transformed into a ribbed one.

Profiling allows to obtain a surface with trapezoidal protrusions with a height of 8 mm.

The standard regulates not only the coverage area in square meters, but also the weight of the products, as well as the permissible color range.

Dimensions (edit)

Standard thickness indicators for C8 grade profiled sheet are 0.35-0.7 mm. Its dimensions are also strictly defined by standards. Manufacturers should not violate these parameters. The material is characterized by the following dimensions:

- working width - 1150 mm, total - 1200 mm;

- length - up to 12 m;

- profile height - 8 mm.

The useful area, like the width, differs markedly for this type of profiled sheet. It is quite possible to clarify its indicators based on the parameters of a particular segment.

The weight

The weight of 1 m2 of C8 profiled sheet with a thickness of 0.5 mm is 5.42 kg in length. This is relatively small. The thicker the sheet, the more it weighs. For 0.7 mm, this figure is 7.4 kg. With a thickness of 0.4 mm, the weight will be 4.4 kg / m2.

Colors

C8 corrugated board is produced both in traditional galvanized form and with decorative surface finish. Painted items are made in various shades, most often they have polymer spraying.

Products with a textured finish can be decorated with white stone, wood. The low wave height allows you to make the relief as realistic as possible. Also, painting is possible according to the RAL catalog in various palette options - from green and gray to brown.

Why can't it be used for roofing?

C8 profiled sheet is the thinnest option on the market, with a wave height of only 8 mm. This is sufficient for use in non-loadable structures - wall cladding, partitioning, and fence construction. In the case of laying on the roof, a profiled sheet with a minimum wave size will require the creation of a continuous sheathing. Even with a small pitch of the supporting elements, the material simply squeezes under snow loads in winter.

Also, the use of C8 profiled sheet as a roof cladding raises questions about its cost-effectiveness.

Installation has to be done with an overlap not in 1, but in 2 waves, increasing the material consumption. In this case, the roof will require replacement or major repairs within 3-5 years after the start of operation. Falling precipitation under the roof at such a wave height is practically impossible to avoid; their influence can be partially reduced only by sealing the joints.

Types of coatings

The surface of the profiled sheet in the standard version has only a protective zinc coating, which gives the steel base anti-corrosion properties. This is enough to create the outer walls of cabins, temporary fences. But when it comes to finishing buildings and structures with higher aesthetic requirements, additional decorative and protective coatings are used to add attractiveness to an inexpensive material.

Galvanized

High-quality galvanized steel sheet of the C8 brand has a coating layer equal to 140-275 g / m2. The thicker it is, the better the material is protected from external atmospheric influences. The indicators relevant to a particular sheet can be found in the quality certificate attached to the product.

The galvanized coating provides the C8 profiled sheet with a sufficiently long service life.

It can break when cutting outside the production hall - in this case, corrosion will appear at the joints. Metal with such a coating has a silvery-white tint, it is difficult to paint without prior application of a primer. This is the most inexpensive material used only in structures that do not have a high functional or weather load.

Painting

On sale you can find a profiled sheet, painted on one or two sides. It belongs to the decorative elements of wall materials. This version of the product has a colored outer layer, it is painted in the production with powder compositions in any shades within the RAL palette. Usually, such products are made to order, taking into account the wishes of the client, in limited quantities. In terms of its protective properties, such a profiled sheet is superior to the usual galvanized sheet, but inferior to polymerized counterparts.

Polymer

In order to increase the consumer properties of the C8 profiled sheet, manufacturers supplement its external finishing with auxiliary layers of decorative and protective materials. Most often we are talking about spraying compounds with a polyester base, but other options can be used. They are applied over a galvanized coating, providing double protection against corrosion. Depending on the version, the following substances are used as coatings.

Pural

The polymer material is applied to the galvanized sheet with a layer of 50 microns. The composition of the deposited mixture includes polyamide, acrylic and polyurethane. The multicomponent composition has excellent performance properties. It has a service life of more than 50 years, has an aesthetic appearance, is elastic, does not fade under the influence of atmospheric factors.

Glossy polyester

The most budgetary version of the polymer is applied to the surface of the material in the form of a film with a thickness of only 25 microns.

The protective and decorative layer is not designed for significant mechanical stress.

The material is recommended to be used exclusively in wall cladding. Here, its service life can reach 25 years.

Matt polyester

In this case, the coating has a rough structure, and the thickness of the polymer layer on the metal reaches 50 μm.Such material resists any stress better, it can be washed or exposed to other influences without fear. The service life of the coating is also noticeably higher - at least 40 years.

Plastisol

Plasticized PVC coated sheets are produced under this name. The material has a significant deposition thickness - more than 200 microns, which provides it with maximum mechanical strength. At the same time, thermal resistance is lower than that of polyester analogs. The assortment of products from different manufacturers includes profiled sheets sprayed under leather, wood, natural stone, sand, and other textures.

PVDF

Polyvinyl fluoride in combination with acrylic is the most expensive and reliable spraying option.

Its service life exceeds 50 years. The material lies flat on the galvanized surface with a layer of only 20 microns, it is not afraid of mechanical and thermal damage.

Various colors.

These are the main types of polymers used to apply the C8 grade to the surface of the profiled sheet. You can determine the option most suitable for a particular case, paying attention to the cost, durability and decorativeness of the coating. It is worth considering that, unlike painted sheets, polymerized ones usually have a protective layer on 2 sides, and not only on the facade.

Applications

Profiled sheets of the C8 brand have a fairly wide range of applications. Subject to certain conditions, they are also suitable for the roof, if the roofing material is placed on a solid base, and the slope angle exceeds 60 degrees. Since a polymer coated sheet is usually used here, it is possible to provide the structure with sufficient aesthetics. A galvanized sheet with a low profile height on the roof is categorically unsuitable.

The main areas of application of the C8 brand corrugated board include the following.

- Fence construction. Both temporary fences and permanent ones, operated outside areas with strong wind loads. The profiled sheet with the minimum profile height does not have high rigidity; it is mounted on the fence with a more frequent step of the supports.

- Wall cladding. It uses the decorative and protective properties of the material, its high hiding power. You can quickly sheathe the surface of the outer walls of a temporary building, change house, residential building, commercial facility.

- Manufacturing and arrangement of partitions. They can be assembled on a frame directly inside the building or formed in production as sandwich panels. In any case, this grade of sheet does not possess high bearing properties.

- Manufacturing of false ceilings. Low weight and low relief become an advantage when it is necessary to create a minimum load on the floors. Ventilation ducts, wiring, and other elements of engineering systems can be hidden behind such panels.

- Creation of arched structures. The flexible and thin sheet holds its shape well, which allows it to be used as a basis for the construction of structures for various purposes. In this case, the arched elements are quite neat due to the weakly expressed relief of the metal product.

Profiled sheets C8 are also used in other areas of economic activity. The material is universal, with full compliance with the production technology - strong, durable.

Installation technology

You also need to be able to correctly lay the professional sheet of the C8 brand. It is customary to dock it with an overlap, with the approach of adjacent sheets along the edges on top of each other by one wave. According to SNiP, laying on the roof is possible only on a solid foundation, with the construction of a coating on buildings that are not subject to significant snow loads. All joints are sealed with a sealant.

When installed on walls or as a fence, the sheets are installed along the crate, with a pitch of 0.4 m vertically and 0.55-0.6 m horizontally.

Work begins with an accurate calculation. It is important to make sure that there is enough material for the sheathing.It is worth considering the installation method - for the fence, they take double-sided materials, for the facade there is enough of a one-sided coating.

The order of work will be as follows.

- Preparation of additional elements. This includes the finish line and starting U-shaped bar, corners and other elements.

- Preparation for the installation of the frame. On a wooden facade, it is made of beams, on a brick or concrete it is easier to fix a metal profile. It is also used in the construction of fences using a professional sheet. The walls are pretreated from mold and mildew, and cracks are sealed in them. All additional elements are removed from the walls of the building during installation.

- The marking is carried out along the wall, taking into account the specified step frequency. Adjustable brackets are fixed on points. Holes are pre-drilled for them. During installation, an additional paronite gasket is used.

- The guide profile is installed, screwed onto the profile with self-tapping screws. The horizontal and vertical are checked, if necessary, the structure is displaced within 30 mm.

- The frame is being assembled. With vertical installation of the profiled sheet, it is made horizontal, with the opposite position - vertical. Around the openings, auxiliary lintels are added to the lathing frame. If thermal insulation is planned, it is carried out at this stage.

- Waterproofing, vapor barrier is attached. It is better to immediately take a membrane with additional protection against wind loads. The material is stretched, fixed with self-tapping screws with an overlap. Roll films are mounted on a wooden crate with a construction stapler.

- Installation of a basement ebb. It is attached to the bottom edge of the battens. The planks are overlapped with an overlap of 2-3 cm.

- Decoration of door slopes with special strips. They are cut to size, set according to level, mounted through the starting bar with self-tapping screws. Window openings are also framed with slopes.

- Installation of external and internal corners. They are baited on self-tapping screws, set according to the level. The lower edge of such an element is made 5-6 mm longer than the lathing. The correctly exposed element is fixed. Simple profiles can be mounted on top of the sheathing.

- Installation of sheets. It starts from the back of the building, towards the facade. Depending on the laying vector, the basement, blind area or corner of the building is taken as a reference point. The film is removed from the sheets, they begin to fasten from the bottom, from the corner, along the edge. Self-tapping screws are fixed after 2 waves, in deflections.

- Subsequent sheets are installed overlapping each other, in one wave. Alignment is performed along the bottom cut. The step along the joint line is 50 cm. It is important to leave an expansion gap of about 1 mm when fastening.

- In the area of openings before installation, the sheets are cut to size with scissors. for metal or with a saw, grinder.

- Installation of additional elements. At this stage, platbands, simple corners, moldings, docking elements are attached. The gable is the last to be sheathed when it comes to the walls of a residential building. Here, the pitch of the lathing is chosen from 0.3 to 0.4 m.

Installation of the C8 profiled sheet can be carried out in a horizontal or vertical position. It is only important to provide the necessary ventilation gap to maintain natural air exchange.

The comment was sent successfully.