How to connect polycarbonate to each other?

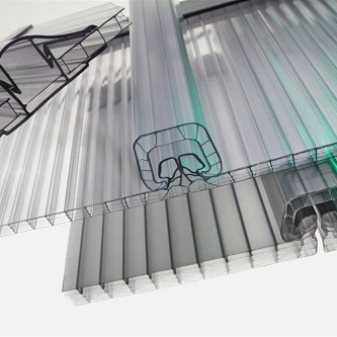

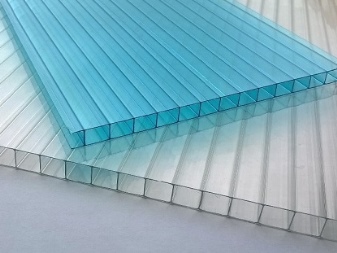

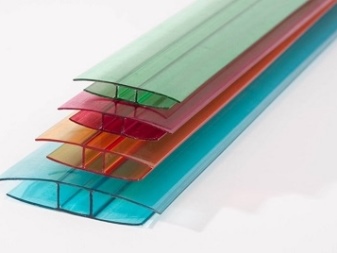

Polycarbonate - a universal building material, widely used in agriculture, construction and other spheres. This material is not afraid of chemical influences, due to which its reliability increases and presentability does not deteriorate. Polycarbonate does not deteriorate due to high temperatures, therefore it is widely used in areas with hot climates. The article will discuss how to connect the sheets together, which is sometimes required when working with this material.

Preparation

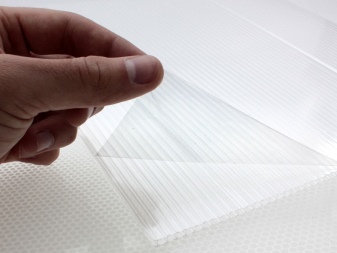

Polycarbonate sheets are cut to the size required by the project using a metal hacksaw or circular saw. Monolithic canvases do not require additional preparation, but for plates with a honeycomb structure, it is necessary to protect the ends in order to avoid contamination and moisture of the channels during operation. If you plan to install at an angle, when the ends remain unused, you need to determine which of the sheets will be on top and which will be below. A sealing tape is glued along the upper edge, and a self-adhesive perforated tape along the lower edge.

Before performing this procedure, you must remove the protective film from the polycarbonate.

Before attaching two sheets of polycarbonate to each other, you need to perform the following procedures and prepare the material:

- cut sheets according to a previously prepared drawing;

- pre-lay the canvases on the future structure;

- remove the protective film;

- clean the joints qualitatively.

For a good connection, you need to perform installation in warm weather... In such conditions, the likelihood of cracking or distortion is excluded. If you plan to join the strips using a connecting profile, then you need to initially prepare the profile systems.

Connection methods

Docking of slabs is carried out in various ways based on materials and purpose. Let's take a closer look at each of them.

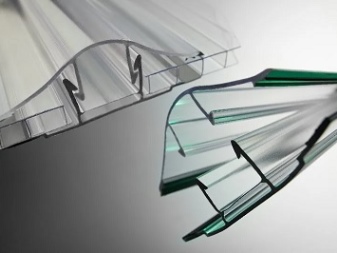

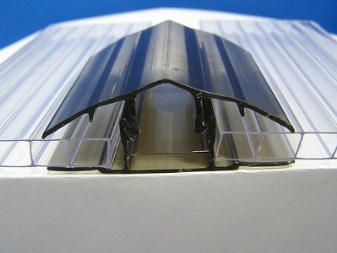

Split profile

This type of installation is convenient if you want to dock parts of the arched structure. The work consists of several steps.

- The lower part of the profile must be attached to the frame with self-tapping screws.

- Lay the canvases so that the edge enters the side at the bottom of the profile and forms a distance of 2-3 millimeters to the top.

- After that, lay the upper profile strip, align and click into place along the entire length, lightly hitting with your hand or with a wooden mallet. When snapping in, it is important not to apply too much force in order not to damage the structure.

A split-type profile made of metal is allowed to be attached as a load-bearing element, as well as to wood structures. In this case, it will perform the additional function of an adjoining node.

Plastic panels are fixed to a solid base. This condition is mandatory when joining polycarbonate on the roof.

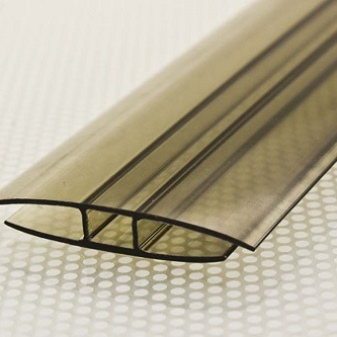

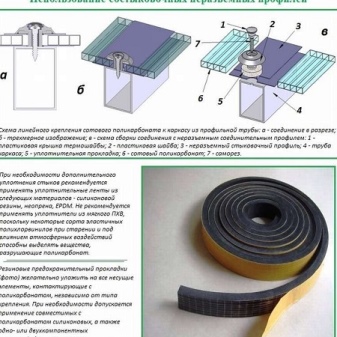

One-piece profile

It is a cheap and very reliable method of bonding polycarbonate. Its use is much simpler than the previous one.

- It is necessary to cut the material to the appropriate dimensions, placing the joint on the beam.

- Fasten the docking profile using self-tapping screws with a thermal washer, regardless of what material the frame is made of. Some use a mount from available tools, which negatively affects further operation.

- Insert polycarbonate into the profile, lubricate with sealant if necessary.

Glue

Docking with glue is used in the construction of gazebos, verandas and other small structures, during the construction of which a monolithic type of canvases is used. The work is done quickly, but in order to get a high-quality and durable connection, you must follow the instructions.

- The glue is carefully applied in a strip to the ends in an even layer. A glue gun is usually used for these purposes.

- Press the sheets together with force.

- Hold for about 10 minutes to carefully glue the joints and move on to the next canvas.

The use of glue allows you to make the joint sealed and solid... Even under the influence of high temperature, the seams will not disperse or crack, but this is provided that a high quality adhesive is used. Usually one- or two-component adhesives are used that will withstand any test and are suitable for any material.

Mainly use silicone based glue. At work it should be borne in mind that the glue sets pretty quickly, and it is almost impossible to wash it off. That is why all work must be done with gloves and very carefully. After the glue dries, the seam becomes barely visible. The strength of the seam directly depends on the density of the joint. When installed correctly, the seam does not allow moisture to pass through.

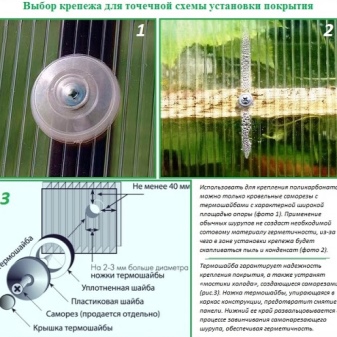

Point mount

With this method of connecting polycarbonate honeycomb sheets, self-tapping screws with thermal washers are used. Since the surface is often uneven, they are used corner mounts... With their help, you can mask areas with joints at an angle. When attaching polycarbonate to wood using a point method, it is necessary to drill a hole with a diameter slightly larger than the diameter of the self-tapping screw. The difference must be at least 3 millimeters.

Such a scheme will avoid deformation during temperature changes. Some experts recommend making an oval hole. With proper observance of all installation rules, you can securely fasten two polycarbonate sheets. Canvases up to 4 millimeters thick can be overlapped, but its width should be exactly 10 centimeters.

Helpful hints

Here are some useful tips that experienced people give to beginners in this field.

- During installation, it is necessary to ensure that the canvases are not located too tightly to each other; it is required to leave gaps of about 4 millimeters. The problem is that when the temperature drops, polycarbonate can both shrink and expand, which makes the structure more fragile. The gap protects the material from kinks and distortions.

- For cutting polycarbonate or metal profiles, it is recommended to use a circular saw with very fine teeth to get an even cut. Some use special band saws. Before joining, be sure to remove the chips.

- It is unacceptable to use a profile as a support or frame element - these are connecting elements.

- Bending of the profile is possible only to the size indicated by the manufacturer in the passport of the goods, otherwise it may be damaged.

- Do not use a hammer when snapping in. It is allowed to use a wooden mallet, but be careful, because it can leave scratches.

- To ensure that the condensate can drain, it is necessary to drill a hole at the bottom of the sheet using a thin drill.

- It is recommended to join canvases of the same thickness and size. This affects the sealing of the joints when joining.

- Metal joining profiles are an important component in the quality construction of structures.

- To prevent the appearance of unaesthetic gaps in the canvas, it is necessary to correctly install the profile. The season plays an important role: for example, in the summer, installation must be done back to back. Due to low temperatures, polycarbonate sheets narrow, and if improperly installed, large gaps are formed between the sheets.

- With a tighter attachment, due to the reduction in size, the slots will be invisible.Such gaps are allowed, as they are conducive to moisture drainage and the creation of the desired level of ventilation.

- In winter, the docking is made with an overlap, but many builders do not recommend installation in the cold season due to possible difficulties. Although, in general, this applies to all construction work.

Thus, the installation of polycarbonate sheets will be the easiest thing in the life of any person. But it is best to ask someone to help, because the sheets are often large, and alone it is impossible to hold them in the right position and carefully connect them.

The basic rules when working with this material are to purchase only high-quality products that meet the requirements, and to carry out installation in accordance with all established standards and instructions.

The following video describes the connection of Kronos cellular polycarbonate sheets.

The comment was sent successfully.