Sand size modulus

The so-called industrial sands are produced with different characteristics. Their main, most demanded and irreplaceable type is construction. The widespread use of a low-cost substrate is also due to the quality indicators of the products, of which it is an integral part. The sand size modulus is one of the main parameters that largely determines the scope of application of a particular group of material.

What is it and why is it needed?

The term "sand" denotes a substrate of free-flowing consistency of nonmetallic formation used in construction. This group includes friable substrates of different types, differing in production methods, parameters of fractions and different impurities. Substrates with a variety of characteristics are on sale. Their main variety, the most widely used and irreplaceable, is sand. The specifics of its use determined the presence of an additional classification.

It is noteworthy that, Despite the rapid growth in the development of the construction industry, this inexpensive and popular raw material still has no worthwhile substitutes. So, natural stone productively replaces brick, concrete elements, block structures; iron and wood products are giving way to the latest alloy and plastic elements. And the sands remain unique and irreplaceable types of natural resources.

It is also significant that the amount of their natural reserves more than sufficiently satisfies the needs of the construction industry and industry.

The vastness of the spheres and the specificity of the use of a free-flowing substrate determine its acceptable physical parameters, which decisively depend on the size of the fractions, grain size and conditions of occurrence. So, it is applied:

- in the medical field - procedures with heated sand (sea and quartz);

- in the field of agriculture (to optimize soil structures);

- in the field of housing (bedding on roads in winter);

- in the art of design and in the aquarium business;

- in construction.

Its types are different, but generalizing characteristics are looseness and structure: oval or polygonal grains with sizes of 0.1–5 mm. The color and special characteristics are determined by the conditions of origin. The most common substrates are yellow, but they can be red, green, black, purple, orange.

It should not be forgotten that the smaller the sand grains have, the more a significant amount of liquid is required to make consistencies from it for construction. Therefore, the smallest types of substrates began to be used for the manufacture of mortars, and substrates of medium parameters are more often used for the preparation of concrete.

According to the methods of obtaining, bulk materials are divided into those obtained in nature and artificially produced. By natural features, their texture can be:

- sea or lake;

- aeolian (wind);

- alluvial (brought by water masses) and deluvial (mined in sediments).

Artificial varieties are produced by mechanical processing of rocks through crushing. They are:

- from expanded clay rocks;

- clean.

The starting material for obtaining such sands are granites, marble, tuff, limestones, which are crushed to obtain the desired structure.

Such substrates are used to create decorative items.

The construction industry remains an important area of application of bulk substrates.At the same time, the higher their granularity, the larger the grains, the greater the strength the system will provide, but at the same time, its quality, such as plasticity, decreases. This determines the specifics of their application.

- Coarse grain optimal for the preparation of high-quality concrete grades, for example B35 (M450), which are used for private sector buildings, the manufacture of tiles, curbs, rings for wells, drainage.

- Medium grain excellently suitable for brick production, the manufacture of popular types of concrete, for example, B15 (M200), used when installing staircases and retaining posts. Squares and paths are poured with this concrete.

- Fine-grained substrates are included in construction mixtures, which are subject to exceptional criteria related to leveling and quality of finishing (plaster, filling fields): where the fineness, evenness and smoothness of the coating are relevant.

In other words, the size of the sand, along with its other qualities, is its main property, which determines the scope of industrial use.... To assess the parameters of the sands, their classification in GOST, a conditional value is used - the size modulus (measured in conventional units), which makes it possible to assess the dominant size of the grains in the batch.

Fineness modulus (MC) refers to the average grain size specific to a particular batch. The used volume of loose sand mass, the consistency of the solutions, the results of work, the quality parameters and the service life of the structures depend on the value of this parameter. The modulus values determine the required volumes of water in solutions, since when there is excess water, the surface of the product will soon crack when it dries.

The indicator corresponds to the size of the fractions of the bulk mass and implies the presence of several types of sands:

- silty substrates (a mass with a fine structure, similar to dust, with grains of 0.05–0.14 mm), subdivided into low-moisture, moist, moisture-saturated;

- small - 1.5–2.0 mm;

- medium-sized - 2–2.5 mm;

- large sizes - 2.5–3.0 mm;

- increased size - 3.03.5 mm;

- very large - 3.5 mm and more.

In practice, it seems possible to track the intended use of sand according to the criterion of Mk values:

- Mk not less than 2.5 (large-sized grains) is used to obtain high-quality concrete B25;

- Mk level 2–2.5 (medium-sized) - for mixtures B15;

- Mk level 1.5–2.0 (small-sized) - for the consistency of underwater concrete;

- Mk level 1.0-1.5 (extremely small) - for the manufacture of fine elements.

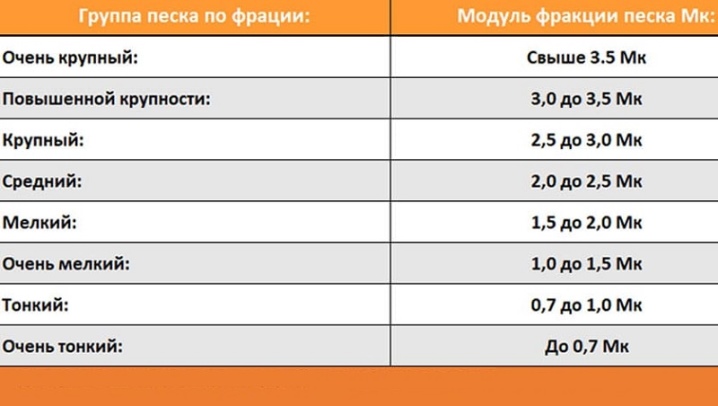

Sand classification by size modulus

According to structural differences and the degree of inclusions of dusty and clayey formations, sand is divided into 2 classes. The size modulus is different:

- category 1 - large, large, medium and small;

- category 2 - large, large, medium, small, very small, thin and very thin.

For each group, specific values of Mk are established. The difference between the classes is that the composition of the worst quality (class 2) includes 3 more additional factions. Small, dusty particles are undesirable in the composition of mortars, since they impair the quality of the bonds between the larger sand granules that bind the cement. Mk values allow dividing substrates into groups and compiling tables:

- extremely fine sands (modulus up to 0.7);

- thin (0.7-1.0);

- small (1.0-1.5);

- very small (1–1.5);

- small (1.5–2.0);

- medium (2.0-2.5);

- large (2.5-3.0);

- increased size (3.0–3.5).

The granularity of the bulk mass can be estimated approximately by eye. However, it is better to measure. To do this, it is enough to pour a little sand near the ruler and compare the sizes of the granules with the values in the table. It is desirable that the substrate be as homogeneous as possible. You should also focus on the color of the sands:

- coarse sands are yellow (closer to beige);

- medium-sized - brighter, more yellow;

- small-sized - pale yellow, light, with a grayish tinge.

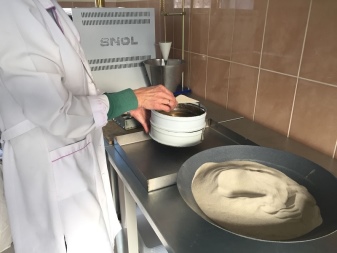

In production, the determination of the parameters of Mk (according to GOST) is carried out in laboratory conditions according to a typical algorithm.

How to determine the size?

According to GOST 8736-2014, the module is measured using a special method.

- From a sample weighing 2 kg using sieves, grains larger than 5 mm are separated. According to the normative parameters of the state standard, the presence of gravel inclusions with dimensions of more than 10 mm in a volume of 0.5% is allowed in sands, and inclusions from 5.0 to 10.0 mm - within 10.0%;

- Residues weighing 1 kg alternately pass through sieves with meshes of 2.5-0.16 mm (5 sieves). Parts of the mass as a percentage of 1 kg, remaining on the sieves, are recorded in the table. The processing process ends when the grains of sand no longer pass through the cells.

- Calculation of Mk is carried out according to the formula Mk = (Q2.5 + Q1.25 + Q0.63 + Q0.315 + Q0.16) / 100, where Q is the parts remaining on 5 sieves as a percentage of the total mass.

The data of the results of the measurements made make it possible to build a graph of the sand screening curve, reflecting the granulometry and giving a picture in which concrete compositions it is optimal to use the material. So, if the curve on the graph is located between 2 lines built according to standard indicators, then the sand satisfies the preparation of the required concrete solution.

That is, Mk is a value that reflects the quantitative characteristics of the grains of the substance, according to which a specific group is determined.

In the physical sense, the formula corresponds to the definition of the weighted average number of grains of a particular size per unit of bulk mass. The higher the level of presence of coarse-grained particles in the samples, the greater the value of Mk.

Nevertheless, this pattern is not always true. Experts note that 2 batches of fine substrate with particles of different sizes may have similar Mc values. It is for this reason that for a high-quality and more accurate description of bulk substances, in addition to Mk, they are guided by other parameters:

- the level of grain size distribution;

- the degree of presence of dusty elements;

- concentration level of clay-like elements;

- level of minor impurity inclusions;

- bulk density level;

- grain density indicators;

- the degree of content of biologically harmful inclusions;

- the degree of activity of radionuclide and other inclusions.

The experts calculate the qualitative parameters of the sands and the purposes of their use in combination, taking into account all the specified parameters, taking into account the value of Mk.

You can find out how the determination of the sand size modulus takes place in the video below.

The comment was sent successfully.