What is foundry sand and where is it used?

A huge amount of natural materials are used in construction. One of the important components is foundry sand. It consists of small grains with minimal inclusions of clay. Molding mixtures are widely used in plastering, foundation backfilling and foundry.

Composition

Molding sands are sedimentary rocks that are formed by the weathering, destruction and movement of rocks. Known for their uniform grain size and high content of impurities. Foundry sand is mined in quarries. The place of detection of a particular species is determined by the shape of the grains of sand. Sharp-angled grains indicate that the material was formed by the destruction of rocks. The rounded shape is formed by exposure to moisture.

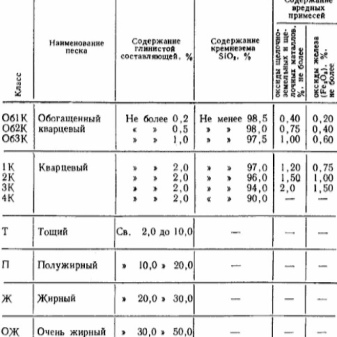

Molding sands, according to GOST 2138-91, can be as follows:

- quartz (clay content not more than 20%);

- fatty (30-50% clay inclusions);

- skinny (up to 12% clay).

As for the chemical composition of the first variety, it is based on quartz. It is a mineral with a density of 7 units. on the Mohs scale. In its pure form, quartz has a transparent structure, but in the presence of impurities, its color changes. The process of converting quartz from one state to another occurs rather quickly when heated. Thus, the mineral is considered a thermally stable material. In the process of exposure to high temperatures, no significant changes occur with quartz, which lead to deformation of sand grains... In addition to quartz, foundry sands contain feldspars, micas, oxides and hydrates of iron oxides.

Impurities of carbonates are considered harmful in sand, which have the specifics of decomposition when heated from 500 to 900 degrees. Also, these inclusions contribute to the formation of various defects in castings.

There is also a certain classification of molding sands:

- distinguish between river, mountain and sea;

- there are large and fine-grained brands (from 0.5 to 3.5 cm);

- varieties are used based on the composition (content of quartz, mica and clay).

The material should not include pollutants: peat, coal and quartzite.

Properties

The main characteristics of this building material include:

- strength - the mixture has a high density and is practically indestructible;

- plasticity - the mass has a tendency to deformation, this is due to the presence of clay inclusions;

- fluidity - the mixture has the ability to evenly distribute inside the container or box for casting;

- gas permeability - the material is able to "get rid" of excess air and gases that are formed during pouring;

- refractoriness - foundry sand has increased resistance to high temperatures.

In addition, its main properties include:

- uniformity;

- high sorption capacity;

- chemical resistance;

- increased flowability and porosity of the structure.

In addition, the molding material is divided into two types (designated by the letters A and B). The first includes a variety with a large residue on the uppermost sieve, on the lower one - to category B. Natural and enriched sands also differ. The latter are obtained by special processing, removing clay and unnecessary impurities from natural sand.

The surface of natural material sand grains is covered with the thinnest films of quartz, iron hydroxides and clay. Grains of sand are very active.The strength and gas permeability of the mixtures depend on the grain size.

Applications

Foundry sand is widely used in the construction field. We are talking about plastering work, making concrete structures, backfilling the foundation, creating a roadbed and developing landscape design.

During construction, it is the river variety that is used. It perfectly permeates water and has excellent flowability.

Foundry sand is used in the metallurgical industry as a reliable filler for iron casting. For foundry, it is quartz sand that is used. Skinny and fatty varieties are relevant for making molds when creating castings from non-ferrous alloys. As for the enriched sand, it is used to obtain rods in hot and cold tooling.

Foundry sand acts as a raw material for the production of high quality glass, which is used in the chemical industry and medicine... Also, this material is an important component in the water filtration system. Molding sands are part of building mixtures and mortars. In the manufacture of self-leveling floors and decorative plaster, various types of sand are also used. It is used as an abrasive material, cleaning metal parts from rust. Also foundry sand used to extinguish the fire of electrical household appliances.

For information on how to make a molding sand, see the next video.

The comment was sent successfully.