Features and applications of seeded sand

Knowledge of the characteristics and application of sown sand is very important for any modern person. After all, the scope of application of dry quarry sand is not limited to construction alone. And even if we talk only about building sand in bags, it is still a very important and interesting substance that deserves close consideration from all sides.

What it is?

For any geologist, sand is just "one of the varieties of fine-grained rock fractions." However, various impurities are added to the fine fractions themselves.

Among them, the greatest role is played by clay, crushed stone and dust-like particles. In their natural form, they look great and together form one of the most valuable breeds on earth. However, it is impossible to use the sand mass in its original form for practical purposes.

Only sown (free from mechanical impurities) sand is suitable for any work. Extraction of raw materials is carried out in sand and mixed (sand and gravel) quarries. In the overwhelming majority of cases, they are developed by an open method. During hydromechanical treatment, the rock mass is developed under strong water pressure. The "wet" option implies extraction by a dredger in water bodies.

The problem is that only the "career" method, with rare exceptions, is economically inexpedient. The processing of the rock is often carried out directly on the spot. However, only thorough sifting and washing (possible, we note, only under conditions of prepared production, with "trough" sinks) can guarantee the excellent quality of raw materials. Refusal to wash is also practiced - in some cases, the end customer needs seeded sand with the inclusion of silt and clay particles. If the task is to maximize flowability, drying with heated gases is practiced.

Properties

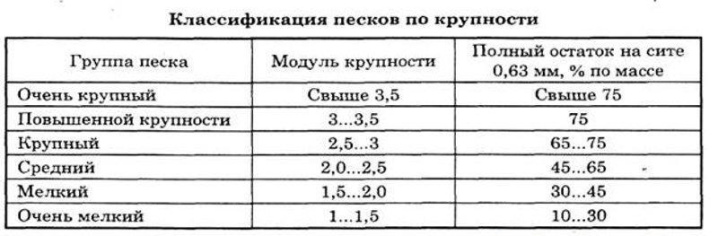

The main properties of seeded sand are the size modulus and filtration index. The linear dimensions of the grains are determined, first of all, by the dimensions of the cells in industrial sieves. The area of use of the material depends on how large the grain is. It is customary to classify sand as follows:

- coarse grain - 3.5;

- middle fraction - 2.8;

- fine grain - 1.54

- the substance of the fine fraction is less than one.

The filter coefficient is considered to be related to the grain size. But it is also influenced by another factor, first of all, the amount of clay substances. After thorough rinsing, the clay completely disappears. This increases the intensity of filtration processes many times over. Sometimes it can reach 10 m in 24 hours.

Seeded sand is distinguished from other types by its very high bulk density. It is generally accepted that for a standard sand mass this figure reaches 1650 kg per 1 m3. But after high-quality sieving, it already increases to 1800 kg per 1 m3. Besides, passing through a row of sieves will definitely increase the filtration quality.

Since water ceases to linger in the material, it is more stable and is able to withstand even harsh cold weather.

Where is it applied?

Continuing the story about pit sown sand, it is worth pointing out its excellent ecological properties... After all, the chemical-physical composition of the substance is normalized, and therefore no problems should arise during its operation. After correct standard processing, the proportion of impurities does not exceed 9% by weight. Often seeded dry construction sand is shipped in bags with a capacity of 25-50 kg.However, it is also practiced to ship in bulk in truck bodies or in the so-called big-bets (MKR) of 1000-1500 kg (of course, this is more suitable for large construction projects).

Well-processed sand is slightly more expensive than raw materials. However, it is used much more. In the overwhelming majority of cases, customers are interested in sandy raw materials with a fraction of 2-2.5 mm. Not only filtration capacity, but also wear resistance (even already as part of a frozen solution) depends on the purity of the product. The specific use of sand depends on its fraction in the first place.

Lots with the finest structure are in demand by factories supplying gypsum-based dry mixes. After all, the finer the grains of sand, the more "graceful" the texture of the finished mixture will be after laying. It's just that fine sand is needed to make bricks (it is used as an additive to clay). Also, this fraction is appreciated by manufacturers of plaster, building mixtures and mortars.

If you ever have to build something on your own, then it is him that is worth looking for.

But do not assume that sand with coarse grains is of no interest to anyone. The situation is exactly the opposite! A coarse-grained quarry product is a part of extra strong concrete and various mortars for masonry. Their plasticity increases with the addition of such a component.

This material is also in demand:

- in the creation of reinforced concrete structures (including rings for wells);

- in the production of paving slabs and curbs;

- as a component of asphalt concrete;

- as a bedding under the roadway;

- as an important component of drainage systems;

- as an auxiliary raw material for various construction;

- in filters of water supply and sewerage systems;

- as a sprinkling of roads and sidewalks with the threat of ice;

- in the improvement of various areas (in landscape design, as they say);

- as a component for planting soil.

The cost of seeded sand is determined not only by its purity and grain size, but also by the location of the quarry. The farther it is from the consumer, the more expensive, naturally, the transportation costs. It is also worth considering the influence of the filling method. Even all other things being equal, it determines the difference in price from 5 to 30%. In addition, the seasonal factor, the market situation, the scale of the order, the possibility of organizing self-pickup also affect.

Washed seeded sand is in any case superior to its river counterpart. The more treatments are carried out, the higher the characteristics of the product. Granules from 1.6 to 2.4 mm are perfect for forming aerated concrete. But this material is also useful for lightweight concrete.

If necessary, the professionals provide all possible consultations.

For more on the features of sown sand, see the next video.

The comment was sent successfully.