All About Dielectric Gloves

Working with electricity is a very dangerous process for life and health, therefore, it requires compliance with certain safety standards. All equipment must be de-energized before work, and the specialist himself can perform his duties exclusively with isolated tools. An indispensable condition is the wearing of dielectric gloves that protect against electric shock.

Let's get acquainted in more detail with the description of these protective equipment.

What is it and what is it for?

The main purpose of dielectric gloves is to protect the hands of an electrician from the danger of electric shock while working with production equipment and networks, the voltage parameters of which go beyond 1000 volts. Special materials from which they are made do not allow the employee to harm himself, they are suitable for installation, adjustment and repair of electrical wiring.

Wearing dielectric gloves is an indispensable procedure for all types of electrical work. Wiring, installation of electrical panels, repair of technical equipment and some other procedures related to electricity in domestic conditions and in production workshops cannot do without such overalls.

Requirements

Gloves for electricians and electricians belong to the group of basic protective equipment, which is why they must fully comply with certain technical characteristics. Among the basic requirements for such mittens are the following.

- Workmanship - no protruding rubber fibers, as well as defective adhesions, cracks and other visible mechanical damage are allowed on dielectric gloves.

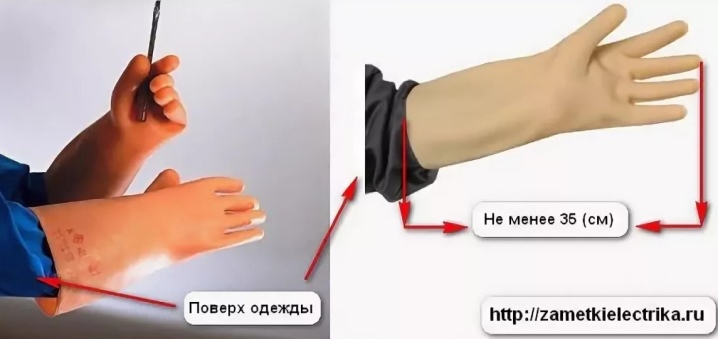

- It is imperative that the glove sizes established by the standards be observed. In particular, their length cannot be less than 35 cm.

- The electrician's protective clothing must have a stamp confirming that the check has been carried out in strict accordance with the established standards frequency.

- Gloves must be free from dirt or moisture.

- A certificate of conformity is required for every pair of gloves.

All of the above requirements are spelled out in the GOST operating in our country.

Species overview

The assortment of electric gloves cannot be called diversified. Latex and plastic rubber sheets are common materials for the production of such workwear. The dimensions of the product are designed so that the electrician can wear insulated gloves or mittens under them during the cool season.

The length of the gloves in most cases is standard, they are worn over the sleeves of protective clothing to minimize the slightest risk of sparks hitting the wearer.

Gloves for working with electricity are classified according to several parameters.

In appearance

Personal protective equipment can be two- or five-fingered, while five-fingered are considered more convenient, since in this case the employee can fully use his hands - thereby greatly simplifying the process of wiring and repairing electrical equipment.

Depending on the manufacturing technology, they are seamless or have a seam. Suture (they are also called ditched) dielectric gloves are made of durable rubber, while the presence of a seam is provided for by their design features - such products are comfortable to wear and lightweight.

By appointment

Depending on the functional purpose

Protective equipment for electricians is made in two versions.

- Models for installations within 1000 V are worn as basic protective equipment when working under overvoltage. It is strictly forbidden to use them in systems exceeding 1000 volts.

- Models for electrical installations of more than 1000 volts - in this case, they act as an additional means of protection, while the work itself is performed using a special insulating tool (electric clamps, all kinds of rods, as well as overvoltage indicators and some other types of professional equipment).

Depending on the maximum allowable voltage

There are several types of dielectric gloves, each of which has its own narrow scope of use. Let's consider each of them separately.

- Class 00 - these are the weakest protective dielectric gloves. As a rule, latex is used for their manufacture, they are used to perform electrical work on low-power devices (household appliances).

- Class 0 - such gloves can be used without the accompanying equipment. They are put on to carry out work on electrical systems, the voltage in which does not exceed 1 kW, these include relatively weak power lines and production mechanisms.

- Class 1 - used for more complex work, for example, on medium-sized production equipment. Such gloves have a tolerance of up to 7.5 kW.

- Class 2 - in most cases, these gloves are certified for voltage protection of 10 kW. Such protective equipment, as well as products of classes 3 and 4, are most in demand in a professional environment, they are universal and have a fairly wide scope - they are used in automotive technology, when installing and setting up machine tools, setting up electrical wiring and other types of work.

Materials (edit)

In accordance with the standards adopted in the Russian Federation, dielectric thermal gloves are made of latex or plastic sheet rubber. The basic requirement for the material used for their manufacture is low electrical conductivity, as well as high plasticity parameters.

Some dielectric gloves can be supplemented with a lining, but may be dispensed with. Depending on the design features, they can have an external coating.

It is allowed to manufacture gloves from various polymer mixtures, allowing many times to increase the parameters of their chemical resistance.

We pay special attention to the fact that if the gloves have an outer coating, then it must necessarily differ in color.

Dimensions (edit)

The length and thickness of dielectric gloves vary depending on their intended use, in accordance with the size table, there are three options for the products used:

- for especially delicate work;

- standard;

- for tough jobs.

The wall thickness of gloves for fine work may not exceed 4 mm, and the wall thickness for gloves for rough work is 9 mm.

As for the requirements for the length of electric gloves, this parameter should not be lower than 35 cm.

Marking

Depending on the features of working units, insulating gloves can be marked with EV or EN:

- EV - worn as an auxiliary protective device, allow you to protect your hands from voltage over 1 kW;

- EN is optimal for operation as a basic protective agent for installations with voltage within 1 kW.

Service life and features of use

Before the very beginning of all types of electrical work, it is necessary to carefully inspect the protective equipment for any mechanical damage: cracks, punctures.

The presence of even the smallest defect is not allowed, since in this case the gloves completely lose their electrically insulating protective characteristics and can begin to pass current, and this poses a threat to the specialist's life and health.

Inspection of gloves for electrical work for breaks and punctures should be carried out not only before starting work, it has a frequency determined by standards - in particular, it is carried out during regular tests. Wherein it is not difficult to determine the presence of damage - for this they just need to be filled with water or twisted in the direction of the fingers, most of the defects are immediately striking.

During work and operation, it is strictly not allowed to roll up the edge of the gloves - this requirement will help protect the skin from injury.

Additionally, you can put on top of the gloves any other products made of tarpaulin or leather.

Dielectric gloves are recommended to be washed in ordinary soapy water or in a soda solution, after which the gloves should be dried as thoroughly as possible. We draw special attention to the fact that they should be dried in a natural way - it is not allowed to use heaters and other heating devices for this purpose.

Glove test

To check the compliance of the technical and operational properties of dielectric gloves with the current requirements of GOST, products are subject to a mandatory test procedure. They are produced both in the factory and directly at the place of their storage.

In experimental conditions, special stands are used for testing; in fact, they are a bath filled with water and an electrical installation. A dielectric glove is placed in a container and filled with ordinary water, while a current of a given strength and frequency is supplied between the reservoir body and the electrode inside the glove. If signs of breakdown are found, the glove is discarded.

This test method is considered the most preferable, since the accuracy of the study in this case is high - due to the use of electronic equipment during the testing process, it is possible to increase the voltage, and at the same time change the current strength so that the test environment fully corresponds to the actual operating conditions of protective clothing.

Dielectric gloves are tested every six months. If the test is successful, the overalls for electricians are stamped, while the impression should be distinct and not wear off during storage - this mark indicates how often the protective equipment was tested, confirms the safety of their use and indicates the expiration date of their expiration.

Any testing of dielectric gloves must be completed by completing a special protocol form. It indicates the dates of subsequent checks, as well as the main parameters of the protective equipment and some other data. This passport must be attached to the gloves and kept with them in warehouses.

Storage rules

The rules for the operation of dielectric gloves prescribe the exact observance of the established storage standards:

- after performing any work, it is necessary to clean as thoroughly as possible of all types of dirt - for this, soap and water are usually used, as well as special antiseptics that are safe for latex and rubber;

- you need to store gloves in places protected from the penetration of UV rays;

- contact of gloves with acid-alkaline solutions, as well as gasoline, essential oils and fats is not allowed;

- in the room where the mittens are stored, the temperature background must be maintained in the range from -30 to + 40 C;

- it is forbidden to store gloves in places with high humidity and strong dust.

Dielectric gloves are considered a practical and reliable item for all types of electrical work. The use of latex and extra strong rubber for their manufacture determines a long period of use of these products. However, it can be extended even more if during the work process the mittens are not wrinkled, but they are put on correctly and not used in those installations where there are sharp edges.

It is better to wear leather gloves over the gloves, which will provide additional protection.

See below for how gloves are tested.

The comment was sent successfully.