How and with what to glue polystyrene?

Expanded polystyrene, which most people call Styrofoam, is a waterproof, lightweight building material that has good thermal insulation properties. It has been popular and widespread for decades. Very often it is used for front, interior and floor insulation. However, the quality of installation and performance of the panels directly depend on the choice and use of adhesives. That is why it is important to know how and how to glue the foam on different surfaces correctly.

Overview of material types

Experienced craftsmen working on large construction projects do not experience difficulties in the selection of consumables. If you want to choose and use foam glue at home, then it is highly recommended to study the relevant information. By the way, the slabs described are often used to decorate not only the outer (facade), but also the inner side of the walls of various premises, including residential ones. Sometimes wallpaper is even glued to the foam, using non-woven glue.

The materials available for installation today can be divided into the following types:

- dry mixes, including tile adhesive;

- liquid formulations;

- polyurethane adhesives;

- polyurethane foam.

At the same time, regardless of the type of expanded polystyrene itself, as well as the characteristics of the base with which to work, it is necessary to remember the following key characteristics of any adhesive composition:

- strength;

- moisture resistance;

- frost resistance;

- drying or polymerization time;

- life time;

- consumption;

- value for money.

Before buying and using glue for gluing plates and other foam products, it is recommended to pay attention to the features of a particular type. And, in particular, we are talking about the composition of the mixture.

Dry mixes

For a long time, such powdery mixtures have been widely and successfully used in both external and internal finishing works. The key to the quality of the composition and the compound itself will be the correctness of its preparation. It is important to follow the manufacturer's instructions carefully. When choosing dry adhesives, it is necessary to focus on the following significant points.

- High strength properties.

- Durability of connections. Subject to the proportions, as well as the correct application of the ready-made solution to the foam sheets, they can last for at least 30 years.

- The ability to use for a wide range of jobs.

- Relatively affordable cost.

In the process of choosing and buying dry adhesive mixtures, it is important to focus on the shelf life. In a situation with high-quality products from renowned manufacturers, it is no more than 1 year. Another key point is proper storage of the powdered glue.

Polyurethane foam adhesive

This type of adhesive, designed specifically for expanded polystyrene and supplied by manufacturers in cylinders, appeared on the building materials market not so long ago. At the same time, glue is gaining popularity at a record pace and is now used by both professionals and home craftsmen. When analyzing its performance properties, it is worth considering the following key features.

- Ease of use. It is best to use a nailer to apply the compound to the surfaces to be joined.

- Versatility. Polyurethane-based foam glue has proven to be effective for pasting with foam on almost any surface, as well as joining panels together.

- Increased strength and durability of fixation.

- Competitive cost and maximum availability.

The quality of the joint depends on the uniformity of the application of the polyurethane adhesive. This refers to approximately the same spacing between points.

PVA

The main advantage of polyvinyl acetate is its availability and low cost. In some cases, this glue is used even when installing extruded polystyrene foam. However, one should take into account the relatively low reliability of the connections.

Given these performance characteristics, PVA is most often used in needlework. If it is used when it is necessary to stick foam panels on a particular surface, then in order to improve the quality of fixation, the composition is applied in two layers, and special dowels are also installed.

Now the most popular examples of mixtures based on polyvinyl acetate are as follows.

- PVA-MB - glue, which contains plasticizers that make it easier to use and improve the quality of adhesion.

- "Moment Joiner" - a universal tool actively used to carry out repair work. The glue goes on sale in packages of 0.1-30 kg. This composition is characterized by minimal drying time and reliable seams.

By the way, some craftsmen attach foam plastic to PVA even to metal bases. In principle, this is possible, but here it is important to take into account the need to use a burlap-like interlayer, as well as the increased consumption of glue.

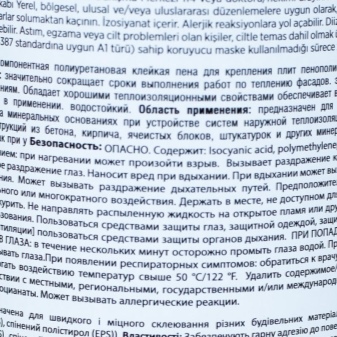

Polyurethane foam

It should be noted right away that this composition is not intended for gluing the material in question. However, nowadays, many craftsmen use polyurethane foam as an adhesive, including when attaching expanded polystyrene sheets to different bases. Its main competitive advantages include:

- strength and duration of fixation;

- ease of use;

- availability;

- price-performance ratio.

However, despite the versatility of the foam, it is strongly recommended that you study the instructions in detail before using it for foam work. It is important to take into account that this type of adhesive can be used both for external and internal decoration.

Liquid Nails

First of all, it is necessary to focus on the availability and relatively low cost of such adhesives. At the same time, they are inferior to competitors in terms of connection reliability and strength characteristics. At the moment, Moment liquid nails are of record popularity. To increase the degree of fixation and ensure the durability of the connections, the installation during the installation of the dowels allows.

It is worth noting that this approach also significantly reduces material consumption, and therefore financial costs.

How can you glue the sheets together?

Often in the process of insulating facades and various structures, as well as when performing other work with foam sheets and tiles, they need to be connected together. In such situations, the question may arise regarding which glue is best for this. In practice, experienced craftsmen prefer to use special formulations for these purposes, which differ in the following characteristics.

- Strength and durability of fixation.

- Moisture resistance.

- Versatility

- Resistance to sharp temperature fluctuations and other negative influences of an aggressive environment.

The most practical and rational option would be to opt for polyurethane adhesives, which are developed specifically for foam. One of their key advantages is the absence of components capable of destroying the structure of the material. In addition, we are talking about the formation of neat, but at the same time the most durable seams. An equally important point is the ease of use, the speed of polymerization, and, consequently, the performance of installation work.

The average consumption of glue based on polyurethane is from 200 to 350 g per square meter. It is important at the stage of selection and purchase to make preliminary calculations, adding about 20% for the stock. As practice shows, processing of the joined surfaces with an abrasive with fine grains helps to reduce consumption.

However, on polyurethane compounds, the list of means for gluing foam elements does not end there. So, for example, if maximum strength is not required, then a relatively cheap PVA is quite suitable. In such cases, the long-term drying of the glue will be the main disadvantage. Very often, masters use the popular Titan brand glue, which is distinguished by good strength. Polyurethane foam and even hot melt glue can also be used. Everything will be determined by the requirements for the installation, and the conditions in which the corresponding work is performed.

How to glue to wood and paper?

An example is situations in which you want to glue letters and other objects made of Styrofoam to plywood, cardboard, and even paper. The most rational solution here would be the use of polyvinyl acetate. The fact is that PVA is ideally compatible with all of the listed materials.

But it is important to remember that this adhesive dries out for a long time, and therefore the joints cannot be touched during the day.

Another way to connect polystyrene foam to a wooden base is to use wood glue. It is able to create the most reliable coupling and at the same time is safe for the foam itself, that is, it does not corrode it. By the way, one of its options is casein glue, which you can make with your own hands based on fat-free cottage cheese.

Bonding with other materials

When gluing expanded polystyrene panels, it is important to avoid serious mistakes, which can often have serious consequences. In this case, one of the most important points will be the features of the material on which the foam must be fixed. With the help of modern adhesives, today the described sheets can be attached with sufficient reliability to concrete, brick and other building materials, as well as to iron, aluminum, wood and even plastic. Of course, each installation option will have certain features. Including the correct selection of glue.

With metal

Often it is required to insulate various metal structures, the list of which includes, for example, garages, change houses and other structures. On the one hand, following the path of least resistance, you can fix the foam with ordinary wire. However, as practice shows, this is far from the best solution. One of the most effective installation options is the use of burlap as a kind of gasket. When finishing small areas inside the premises, it is possible to use even high-quality double-sided tape.

Correct and careful processing of the base will be the key to a strong connection. It is strongly recommended to clean the metal surface from rust, paint and other contaminants, as well as degrease. Directly for gluing foam, you can use:

- aerosol glue;

- silicone based sealants;

- assembly and polyurethane foam.

The best option is most often the use of one-component polyurethane compounds.

This choice will be most relevant when attaching sheets to an inclined or uneven metal base.

With cloth

Several modern compounds will help to glue different types of fabric to expanded polystyrene or fix a rope (woolen thread) on it. So, such compounds will make it possible to make PVA or hot melt glue, which is now popular. It is important to take into account that the first dries much longer, but at the same time provides a stronger connection. Excess glue at the joints and seams in both cases can be removed with a sharp knife so that they become almost invisible.

With plastic

Fixation of foam on plastic substrates is carried out in the overwhelming majority of cases using polyurethane foams, as well as epoxy glue in tandem with special fasteners in the form of dowels. When choosing an adhesive, it is important to pay attention to the absence of components that can interact with both the expanded polystyrene itself and with plastic. The list of surfaces unsuitable for mating includes the following.

- Formulas with the presence of acetone, which is allowed to be used only at the preparatory stage for degreasing.

- Derivatives of petroleum, that is, gasoline, diesel fuel, kerosene, xylene and substances that are their analogues.

- Alcohols, which can be found in adhesives, primers and processing fluids.

With concrete

You can attach expanded polystyrene to such a base without equipping the crate, that is, just stick it. This can be done both outside the house and indoors. By the way, they do the same with well-executed brickwork. To complete the work, you will need a primer, equipment for diluting the mixture (mixer with a nozzle), the glue itself, as well as a spatula for applying it.

In the overwhelming majority of cases, when finishing concrete surfaces, they make a choice in favor of dry mixes. Dilute such powders with plain water in proportions that are indicated in the manufacturer's instructions. After preparation, the resulting solution is allowed to brew a little. The key to high-quality adhesion will be the correct preparation of the concrete base.

In addition to powder products, craftsmen in some cases use sealants and liquid nails.

The best glue manufacturers

Today, adhesive mixtures for various construction and finishing works are produced by many manufacturers. Naturally, this also applies to compositions for fixing polystyrene foam. One of the fairly popular is Soudal brand products... In this case, we are talking about a Belgian family company specializing, among other things, in the production of sealants and aerosol foams based on polyurethane. For more than half a century, this manufacturer has been presenting a high-quality product on the market in 130 countries.

According to numerous reviews, one of the undisputed leaders in the industry is Ceresit brand... The company's catalog contains a fairly wide range of mixtures designed for gluing foam sheets to each other, as well as their reliable attachment to different bases. The key competitive advantages of the products of this brand include the following.

- Fast hardening (taking into account the type of adhesive composition 2-3 hours).

- Increased resistance to temperature fluctuations and frost. For example, Ceresit foam can withstand drops in the range from -20 to +40 degrees.

- Good moisture resistance.

- Versatility.

- Can be used on any surface.

The manufacturer offers the potential consumer a large selection of glue. We are talking about high-quality dry mixes, aerosols and foams designed for both outdoor and indoor use.

The next popular brand is Knauf. Now a range of products is presented on the market, which is characterized by:

- strength and durability of connections;

- frost resistance;

- increased resistance to the negative effects of moisture;

- the ability to use when performing work of any complexity, regardless of operating conditions;

- fast solidification.

Another well-known manufacturer is Tytan... The company produces several types of adhesives that are durable and easy to use. The products of this brand are widely used by craftsmen for gluing foam and fixing it on various materials. Adhesives are relevant for external and internal work. Today, Tytan Styro-753 has become the most popular, which has such important advantages:

- polymerization rate;

- ease of application on the surface;

- resistance to both high and low temperatures;

- good strength;

- optimal ratio of cost and quality;

- affordable price.

For many years, the leading positions in popularity ratings have been occupied by products under the brand name "Moment"... In this case, we mean liquid adhesives and dry mixtures for work, including with expanded polystyrene. In addition, the manufacturer's catalog contains high-quality polyurethane foam, characterized by increased performance. The key competitive advantage of formulations of all categories can be confidently called the optimal ratio of price and quality.

Also in the top 5 most demanded brands is Technonikol... This company in the relevant market segment produces high-quality foam, the performance of which has already been appreciated by many specialists. It has proven itself exclusively on the positive side when performing work of varying complexity, involving gluing foam on brick, concrete, wood, plastic and other surfaces. Foam for the winter and summer seasons goes on sale.

General rules for choosing a tool

In order to choose the most suitable adhesive solution in a particular situation, it is necessary to pay attention to the study and analysis of both the characteristics of the applicants and the characteristics of the base. It is important to remember that one of the key parameters is the strength and durability of the joints. Equally important will be the compliance of the adhesive with current standards and regulations.

And first of all, it is worth making sure that there are no substances in the mixture that are potentially dangerous to expanded polystyrene:

- acetone and ketone solvents;

- nitrobenzene as well as nitromethane;

- chlorine;

- kerosene and gasoline;

- other flammable ingredients.

It is important to remember that even the minimum content of the listed substances can have an extremely negative effect on the structure of foam panels and other products made of this material.

Another key point is the purpose of the adhesive. This means that this or that glue is focused on interior or exterior work. When it comes to exterior decoration, the main characteristic is resistance to fluctuations in temperature and frost. You should also clarify what types of surfaces the mixture is intended for.

The comment was sent successfully.