How to insulate floors in a house with polystyrene foam?

Warm floor in the house always helps to create coziness and comfort for the family. If all the walls and windows are insulated in the dwelling, and the floor remains cold, then all efforts to save heat will come to naught. Only if the floor is insulated, heat will be retained in the room, and heating costs will decrease. For thermal insulation of the floor, polystyrene or its kind of penoplex is used. When choosing a material, you need to take into account its quality indicators, fire safety, environmental friendliness and installation method. For beginners, the styling process may seem daunting, but it's actually pretty straightforward and easy.

Pros and cons of insulation

Most often, foam is used for floor insulation. This is due to its quality indicators and characteristics:

- high level of thermal insulation;

- does not allow moisture and cold to pass through;

- high wear resistance;

- resistance to moisture and water;

- low price;

- environmental friendliness in comparison with other materials.

If the floors are properly insulated with foam, the coating will last several decades, mold will not form on it, there will be no excessive moisture or dampness in the house, it will be cool in summer and warm in winter.

Polyfoam is convenient to use for thermal insulation of the floor under the screed. The material is chosen because of its economy, ease of transportation and installation, as well as ease of installation. Styrofoam sheets can be easily cut with an ordinary knife, they can be given any desired shape without unnecessary labor.

Due to the lightness of the material, the structure is lightweight. And its strength and rigidity allow it to be laid on almost any surface. Fungus and mold do not develop in the foam, dampness does not harm the room.

Among the disadvantages of the material, it is worth noting its toxicity after contact with nitro-based paints. Polyfoam under its influence begins to self-destruct and emits chemical vapors. Also, the material is airtight: if all walls and floors are insulated with foam, the house will not breathe. Polyfoam does not burn, but begins to melt, not spreading the fire further, but at the same time emitting poisonous fumes.

When using foam in rooms with high traffic, it is worth additionally creating a reinforcing frame in order to avoid subsidence and deformation of the floor covering and to protect the material from mechanical damage.

In general, when used correctly, polystyrene is harmless to human health.

Tools and materials

For high-quality thermal insulation of the floor, you should choose the right insulation, taking into account its density and sheet thickness. For floor insulation with wooden logs, foam plastic with a density of 15 kg / m3 is suitable. The lags will take on most of the load, so the foam can be used with a low given indicator.

For floors where the foam will directly take all the load, a material density of more than 30–35 kg / m3 is required, which will prevent the cement or concrete screed from sinking and further deformation of the floor.

The thickness of the material is selected exclusively on an individual basis. Sometimes it is chosen intuitively, but you can also use a special calculator to calculate the size of the cross-section of the insulating layer.

For floors with numerous voids and irregularities, liquid foam (penoizol) is often used. It is also suitable for insulating batten floors. The voids are filled with foam on top of the waterproofing film and wait for the required time to solidify.

It is better to choose foam sheets with profiled edges, which will avoid cracks at the joints. If you leave narrow holes, cold air will accumulate there, and in the future so-called cold bridges will appear.

In addition to foam sheets, you will need to insulate the floor:

- foam glue;

- waterproofing material;

- assembly tape;

- damper tape for laying seams and joints;

- reinforcing mesh;

- cement, sand or a special mixture for preparing screed mortar;

- self-tapping screws;

- screwdriver and level;

- chipboard sheets and wooden beams (if you decide to insulate the floor with a lath from a lag).

Depending on the method chosen and the individual characteristics of the room, the list of materials and tools may vary.

Installation technology for different floors

There are several ways to install foam for floor insulation. The choice of this or that option depends on the material of the floor covering. But any technology is quite simple to implement, and anyone can insulate floors with their own hands.

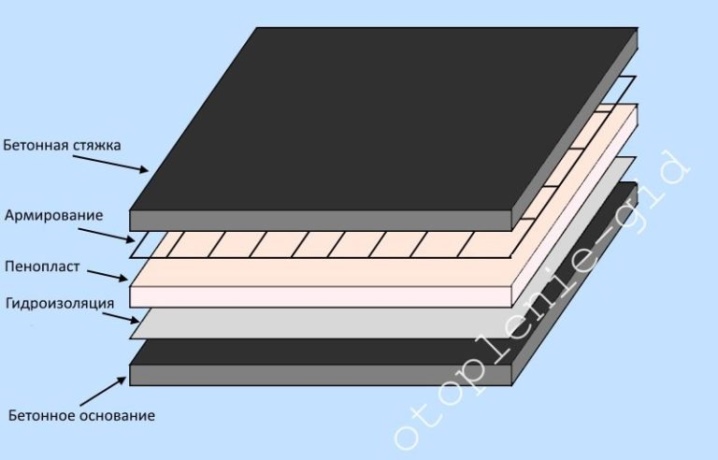

In a private house, polystyrene is used under the screed on the 1st floor. Thus, hydro and thermal insulation of the entire room is provided. Dampness and cold from the basement do not pass into the living rooms. The foam is laid on the waterproofing after the rough screed.

The technology for installing polystyrene is not much different in a wooden, brick or concrete house. There are 2 mounting options: from above and from below. The second option is more correct from the point of view of heat preservation, but laborious. In most cases, they are installed on top of the floors.

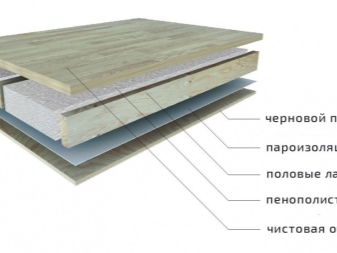

Laying foam on wooden joists can be used in a wooden house. To do this correctly, you must first level the surface, lay a waterproofing layer. You can also additionally impregnate frame logs with a special tool for resistance to mold and mildew. Only after that is the foam or liquid penoizol laid. From above, the insulation must be covered with chipboard sheets. For steam and waterproofing, it is better to use more expensive special materials instead of conventional films.

It is important to arrange the layers in the correct order and carefully seal the joints and crevices. If the technology is violated, then the thermal insulation will not work, all the costs will be useless.

When using foam for flooring on the ground, the technology is similar. First, the top layer is leveled, the cracks are closed. The insulation is laid loosely (without tension) and must have an overlap of 10 cm. After that, the insulation is laid, and a vapor barrier is placed on top. When insulating the floor on the ground, additional reinforcement is necessarily used to increase the strength of the foam. For pouring, use a concrete or cement screed. Before screed, it is imperative to fill the slots and joints with foam, and secure the foam sheets securely with self-tapping screws or dowels. Next, you can lay the flooring. This type of insulation can also be used under laminate flooring.

In a log house, it is better to carry out insulation at the stage of pouring the concrete floor. Thus, the profile bar will not collect excess moisture from the accumulated condensate, and the floors will last longer. During installation, it is necessary to use additional waterproofing materials and antiseptics to avoid the appearance of fungi and mold.

Insulation of the floor in houses on piles is especially important. Such structures are usually located in areas with high humidity. And the absence of a basement creates additional heat loss. When insulating the floor, it is worth considering the design features of the building. It is better to use a three-layer cake made of breathable waterproofing, insulation and an additional layer of vapor barrier.

Insulation of a concrete floor with foam in the video below.

The comment was sent successfully.