Features and application of foam

For many decades, foam has been actively used in various industries. There are several varieties of this material. In order to use it correctly, you need to know the nuances of production, as well as the principles of installing foam.

What is it and what is it made of?

Styrofoam is a white material. It has a low weight, has a lot of different characteristics, due to which it is widely used in various fields. Polyfoam is 98% air, and the remaining 2% is expanded polystyrene. Despite the small percentage, the material contains billions of cells of this substance.

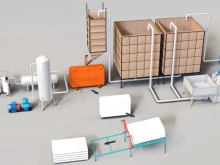

Foam production is carried out on special equipment. Initially, raw materials are delivered to the workshops, from which foam plates with various thicknesses and densities are obtained at the exit. Polyfoam is made from almost any polymer. The primary raw materials can be: polyvinyl chloride, polyurethane, polystyrene, phenol-formaldehyde and many others.

The production of the material is carried out in several important and sequential stages:

- foaming;

- drying;

- stabilization;

- cutting;

- maturation;

- baking.

Initially, foam is a liquid mass that goes through all stages. At the exit, plates of different thicknesses are obtained. The popularity of polystyrene is primarily due to its low cost. And also it has many useful properties: good sound insulation, does not allow moisture to pass through, retains heat.

In addition, the foam can be easily cut straight or curved using standard tools (knife, hacksaw, heat knife).

Characteristics and properties

Polyfoam has a number of technical characteristics.

- Strength. Here indicators vary from 0.05 to 0.16 MPa. This indicator is directly dependent on the polymer that was used in production as a primary raw material.

- Thermal conductivity. The maximum value is 0.043 W / (m · deg). This indicator also depends on the quality and properties of the primary raw materials.

- Frost resistance. For ordinary foam, the indicators reach 200 cycles. If the material is extruded, there may be 500 cycles.

- Moisture absorption is insignificant - only 1% per day. But this does not mean that moisture does not penetrate into the material at all. If it stays in the liquid for a long time, it will eventually fill the entire air space between the polystyrene cells. In this case, the foam will lose most of its original properties.

- Fire resistance - Styrofoam is considered a non-combustible material. When exposed to flame, destruction and discoloration of the surface is allowed. Although it does not burn, it can melt (melting point is 120 degrees Celsius).

- The cost of foam varies depending on various factors. This can be the rank of the manufacturing company, the region of sale, the cost of the initial raw material. But on average, the price is 3 thousand rubles for each m3.

- Sound insulation - depending on the thickness, it can absorb up to 32 dB. This figure is considered good, but despite this, sound insulation when using mineral wool will be higher.

- Water vapor permeability is 0.03 mg / mhPa. It is believed that this material does not participate in the formation of natural air exchange between the room and the street.

Polyfoam belongs to the category of environmentally friendly materials. And its service life is from 10 to 80 years.

Views

There are several varieties of this material. First of all, it differs in thickness: the minimum is 20 mm, and the maximum is 100 mm. Granules can also be of various weights and diameters.

In addition, foam can be divided into 4 broad categories. Each of them includes a certain type of material that differs from others in appearance and other characteristics.

Polystyrene

This type differs in that it is produced in two ways.

- Pressless - consists of small balls. Expanded polystyrene in processed form is just used as a packaging material for the transportation of various household appliances. The material produced by the non-press method is quite fragile (it can be easily broken by hand). Sometimes it is sold as crushed (in packaging material).

- Press. It differs in that the granules are fastened to each other much stronger. The material is sold in hard slabs. This foam can only be cut with tools. Manufacturing is more expensive, so press foam is less common.

The main advantage of this type of material is its high hygroscopicity. If we talk about durability, then in the unpressurized one it varies from 10 to 35 years. Pressed can last up to 70 years. These indicators are conditional, since the correct installation and the initial quality of the material affect a lot.

Polyurethane

Foam rubber can be cited as the most striking example of polyurethane foam. Its peculiarity lies in its porous structure, it is good for steam and air. When exposed to fire, it can release toxic substances. Compared to polystyrene foam, it is very short-lived. It is used most of all in the manufacture of furniture, for example, as upholstery.

Polyvinyl chloride

Polyvinyl chloride is a specific material that is presented in the form of thermoplastic polymers; more than 50% is made from combined chlorine. It is because of this that it is rather poorly subject to combustion. The indisputable advantage of this material is that there are no toxic substances in it. And in case of fire, it is able to extinguish on its own. Possesses high plasticity.

Lack of material - it is not recommended to use it in close proximity to metal surfaces. This is because PVC foam can damage the metal.

Polyethylene

Polyethylene foam is also considered a traditional packaging material. It looks like a film that has air valves (pimples) on one or both sides. Initially, it is a liquid polymer, which, bypassing all production stages, turns into a film of various thicknesses. It is considered an environmentally friendly material. With proper operation, it can serve for quite a long time. The only drawback is that it is a flammable material.

Marking

For foam, which is produced in the territory of the Russian Federation, there are corresponding markings. In them, as a rule, the quality characteristics of the material itself are encrypted. So, the numbers indicate the size of the material. Construction foam is marked PSB-S 50.

As the numbers decrease, its characteristics change. So, PSB 15 is more suitable for finishing surfaces, for example, walls. Marking is necessary, because on its basis, buyers choose a material with the necessary set of quality characteristics.

Manufacturers overview

Due to the high demand and popularity of this material, many companies are engaged in its production. The largest and most famous are several brands.

- TechnoNicol Is a fairly large company with branches in the CIS and Europe. Production is carried out in more than 100 factories.

- URSA - originally a Spanish concern that began operating in Russia in 1995 in the city of Chudovo. Then another plant was opened in Serpukhov, near Moscow.

- "Penoplex" - a manufacturer operating since 1998 in St. Petersburg. The product catalog was initially divided into two broad categories: for home and professional use.

- "Tepleks" - the Nizhny Novgorod plant, which began its work back in 2005, and since then has been successfully selling high quality material.

- "Timplex" - the oldest enterprise of all of the above. Initially, it was a chemical plant named after Karpov. The opening took place back in 1868. Since then, production has kept pace with the times. Relatively recently, the production of foam of various types has been established there.

These are not all manufacturers. There are also smaller businesses that also produce high quality foam.

Applications

Polyfoam has found wide application in various fields.

- Construction. Here, the material works well as wall and floor insulation for rooms. In addition, foam is often used to create sound insulation in apartment buildings, as well as other buildings and structures when screed floors and walls. It is laid as thermal insulation under the foundation. Noise isolation is the main focus.

- In shipbuilding Structural foam is also used in the manufacture of rescue harnesses and other accessories for the same purpose. Small boats and rafts can be made from this material, since it is very light and will always stay on the surface of the water.

- In various industries Styrofoam is used as packaging material. So, it is suitable for packaging food, and for transporting household appliances and other goods.

- In the manufacture of furniture.

It should be noted that foam is used not only on an industrial scale, but also at the household level. There are also many areas of application here.

- Very often, fishermen from polystyrene make homemade floats for fishing. Styrofoam floats well. It is enough just to paint a small piece of material in a bright color - and the float is ready.

- In needlework, polystyrene is also often used. Styrofoam balls resemble snow in appearance, therefore, they are suitable for creating compositions on the relevant topic. Patchwork (creating pictures from scraps of fabric) is also not complete without the participation of this material, for this you just need to tuck the fabric into the grooves cut in the foam.

- Styrofoam is good for creating various types of toys and children's furniture.

And these are far from all areas of use of this universal material.

Installation features

Styrofoam installation is one of the easiest. This is because the material itself is quite light in weight. There are various ways to attach different types of foam to other surfaces:

- double sided tape;

- glue (non-aggressive compounds that do not corrode the foam itself);

- dowels;

- staples;

- buttons.

Fastening options can be very diverse. If the material is tightly tucked between the walls as insulation, in general, it may not be additionally fastened in any way.

Nuances of processing

Despite the fact that most types of foam are environmentally friendly, it still needs to be properly disposed of. There are three main ways to process Styrofoam:

- splitting up;

- pressing;

- dissolution.

The most common and easiest way to recycle is crushing. After crushing into small particles, the recycled foam is placed in a special container.In the future, it can also be used as a filler. Pressing or compacting - this method is designed to reduce the volume of the material. In this case, the foam plates are not crushed, but exposed to the press and high temperature. As a result of such processing, its volume is reduced by at least 10 times.

Compaction is carried out in three stages:

- compression;

- softening;

- saw cut.

Expanded polystyrene is a product of a chemical reaction, therefore it undergoes dissolution. As a reagent, mixtures are used here, the main component of which is benzene. Under its influence, the foam turns into a thick, but liquid mass. In order to properly dispose of waste, it is necessary to hand it over to a collection point. There, the foam will be sent for further processing. As a secondary raw material, it can be used to generate energy, as a component in the preparation of concrete mortar, and also as a raw material in primary production.

The comment was sent successfully.