Insulation of the blind area with penoplex

House on a concrete foundation without fail must have such an element as a blind area around the perimeter. The side walkway can be up to one and a half meters wide and perform a number of tasks. Basically, it is responsible for the durability of the building, helps to remove moisture from the base of the building and reduces heat loss through the basement and underground part. And also the blind area can serve as a driveway, garden path or decorative addition that favorably emphasizes the lining of the basement.

The blind area around the building does not always need thermal insulation. The need for its device arises when building a house on clay soil and in severe frosts. And also you can not do without it on heaving soil that freezes unevenly. During the thawing process, it can cause the foundation to shift and crack. In addition, a warm blind area should be planned if there are plans to use the basement for domestic purposes.

Advantages and disadvantages

Thermal insulation of the blind area should be moisture resistant, prevent the appearance and spread of fungal microorganisms and mold. At the same time, safety when working with it is important and its inedibility for frequent inhabitants of basements - representatives of the order of rodents. Important points when choosing materials for insulating the blind area:

- ease of installation;

- resistance to temperature changes;

- practicality;

- fire safety.

The most suitable option that meets all of the above criteria is a board material known as expanded polystyrene. It is obtained by foaming liquid styrene, baking cellular granules together. Micropores with air are formed inside them, which in itself is an excellent heat insulator. Penoplex differs from competitors in a whole range of advantages:

-

high moisture resistance;

-

long service life - extruded polystyrene foam in the soil may not lose its heat-shielding properties for a whole century;

-

low compression ratio to cope with mechanical stress;

-

low relative mass of slabs;

-

resistance to subzero temperatures;

-

safety and environmental friendliness.

In addition, insulation of the blind area of the house with penoplex prevents soil movement in relation to the plinth, which means that the cladding of the base of the wall is possible using all kinds of materials.

Since the insulation of the blind area belongs to legalized thermal engineering measures, when planning its device, it will be possible to save on the depth of the foundation, reducing the cost of excavation and concrete work.

And also a warm blind area made of extruded polystyrene foam reduces the cost of heating the house in the cold season.

What other advantages does this option provide? Convenient size and low weight of the boards facilitates quick installation using the simplest tools. A penoplex blind area device around the house is available even for people who do not have construction education and special skills. The tongue-and-groove system of joining the slabs promotes fast and maximally dense laying.

Of the disadvantages of insulation with expanded polystyrene, it is worth noting its flammability and the likelihood of interest in it from rodents.

But both shortcomings can be neutralized if you use protective layers in the form of non-combustible materials and a reinforcing mesh, which will be too tough for small pests.

Material selection

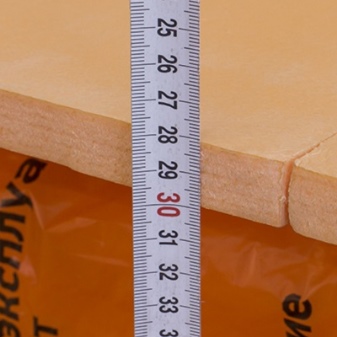

It is optimal to choose extruded polystyrene foam in plates for insulating the blind area. They are produced in different brands, thicknesses and dimensions. Most of the properties of a material are determined based on its density: the larger it is, the correspondingly higher strength, less hygroscopicity, moisture absorption and air permeability. Extruded polystyrene foam has the best density and water resistance characteristics. The size of the slabs is 600x1200 mm with a possible thickness of 30 to 100 mm. In this case, the sheets of standard polystyrene foam have a thickness of 20 mm, and for the insulation of the middle part of the blind area, it is preferable to choose EPP from 50 mm, and for corners from 60 to 120 mm, since in these zones there is always maximum freezing.

How to insulate with your own hands?

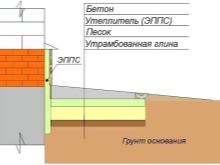

The layout of the thermal insulation device around the building is simple and does not require complex manipulations. The result will please you with an increase in thermal insulation by 20%, and if you also try to insulate the basement, then even in winter on the lower floor the temperature will not be lower than +10 degrees. It is necessary to proceed to the device of the blind area immediately after the foundation and external walls have been erected. Layer-by-layer blind area consists of geotextile, crushed stone, washed sand, insulation and facing material.

It is recommended to engage in insulation during the warm season, which greatly simplifies the excavation work preceding the main process.

Preparation

First, you need to prepare the base for the blind area. Using pegs and a cord, make a breakdown of the perimeter of the working area. The width of the blind area is planned at least 60 cm. Primarily, this parameter depends on the size of the roof overhang. The width of the blind area should exceed it by 30 cm or more. Determining the width of the trench, one should proceed from the dimensions of the foam sheet. This will reduce the amount of waste material.

The main difficulty in arranging the blind area is not so much the process itself as the calculations themselves, the result of which is influenced by two factors - the size of the roof overhangs and the type of soil in the area being developed.

On ordinary soil, the width of the blind area should exceed the eaves overhang by 20-25 cm.If we are talking about a house on collapsible soil, then the width of the blind area is planned to be at least 90 cm. It is necessary everywhere to observe the same distance from the outer edge of the blind area to the walls of the house. Having finished with the calculations, you can begin to prepare the base for the blind area.

To complete the preparatory work, you will need:

-

shovels of shovel and bayonet type for trenching;

-

construction wheelbarrow to carry out the removal of soil;

-

cord for marking;

-

building level to determine the desired slope;

-

perforated pipe;

-

materials in the form of clay, sand, crushed stone, roofing material and geotextiles as an underlying layer.

It is of paramount importance to correctly mark the groove. All vegetation is preliminarily removed along the perimeter of the house, and the contour of the planned structure is determined with pegs. They are hammered in at the corners, keeping a distance of 2 m.

Having finished with the markings, you have to deal with the trench. It is recommended to go deep into the ground by about 40 cm, which corresponds to 1.5-2 bayonets of a shovel.

Then, a 5-centimeter layer of clay is laid on the bottom of the recess and roofing material on top, which is here determined the role of waterproofing. After these manipulations, the trench is covered with a 10 cm layer of sand, which is important to tamp thoroughly.

Now you can start the formwork device.

It is easiest to assemble it from boards, and then fix it according to the markings along the outer edge of the planned blind area.

Geotextiles must be placed on top of the sand layer. Thus, its destruction from the influence of weather conditions is prevented and drainage is carried out to drain water from the structure.

At the next stage, crushed stone with a layer thickness of about 15 cm is placed in the formwork.It should also be tamped. All laid out layers are made with a slope of 3-5% in relation to the walls of the building.

Next to the blind area, you will need to conduct a drainage channel using a perforated pipe. It is placed on the lower level of crushed stone, previously wrapped in geotextile.

This approach will protect it from getting inside soil particles and avoid blockages.

Technology

After the installation of the underlying layer has been completed, the main working stage begins - the insulation of the blind area with expanded polystyrene. For work you will need:

-

insulation in slabs;

-

bituminous mastic;

-

cement grade M300-M400;

-

waterproofing;

-

reinforcing mesh;

-

concrete mixer;

-

Master OK;

-

deep containers such as buckets.

Prepared foam plates are laid on the compacted gravel in 2 layers. The cake of the insulating coating should not have through seams. The seams of the slabs in the first row must be covered with the slabs of the second row. This is necessary to prevent the appearance of so-called cold bridges in the insulation. The gaps between the slabs and the walls are filled with waterproof foam.

Then the insulating coating is covered with a reinforcing mesh, the canvases of which are overlapped by 10 cm. This is dictated by the intention to prevent the mesh from shifting during the pouring of the formwork with concrete. In addition, it is necessary to raise the reinforcing mesh above the foam layer by a couple of centimeters so that it is in the middle of the future concrete layer. For this, in the formwork without concrete, fragments of insulation are placed under the mesh.

So that in the future, cracks do not form on the concrete screed of the insulated blind area, for every 2-2.5 m, expansion joints will have to be created in it. To do this, before pouring, ribs of vinyl tape or wooden boards with a width of no more than 20 cm are laid across the formwork. It will be correct to place additional expansion joints in the areas of maximum structural stress.

After partial hardening of the solution, the boards can be removed, and the seams formed in their place can be filled with sealant. If you plan to leave the boards in concrete, they must be covered with a protective layer of bitumen mastic before laying.

Boards that form expansion joints, it is advisable to install at an angle in accordance with the slope of the blind area... Subsequently, these boards will serve as beacons, along which it will be easier to level the concrete mixture using the rule.

Pouring concrete mortar into the formwork should be done in portions corresponding to the number of cells created by transversely arranged boards. The thickness of the concrete layer is 5 to 10 cm. A large thickness is undesirable, since cracks may appear from temperature changes in the blind area.

After pouring in the initial stage of hardening of the concrete composition, it is better to apply a special waterproof composition "Crystallisol W12" to the surface.

If, according to the project, a warm basement is provided in the house, then the basement and foundation from the outside are also insulated with expanded polystyrene. Moreover, the foundation takes on the main loads and is responsible for the stability of the building as one of its main components. You will first have to make complex waterproofing measures using bituminous materials.

Various materials are used to finish the finished blind area: clinker, porcelain stoneware, staining, natural or artificial stone, cobblestone, paving slabs and others. The best option for the ratio of price and quality indicators is paving slabs.

Thus, insulation and waterproofing of the foundation and blind area is carried out without any problems. This is a completely affordable enterprise, especially if you follow the scheme and observe a strict sequence of stages and the quality of their implementation.

You can learn how to properly insulate the blind area with penoplex from the video below.

The comment was sent successfully.