How to make a concrete blind area?

Even the strongest foundation cannot withstand moisture and temperature changes for a long time. Moisture quickly increases the stress on the drainage system and waterproofing of the house. To avoid this, a concrete blind area is installed. This is quite simple to do on your own. This is what this article will be about.

In addition to performing the main functions (preserving the structure from the destructive effects of moisture), the coating becomes an area for pedestrians. In addition, the blind area gives a private house a special beauty and a finished look. However, before directly pouring the blind area, it is necessary to analyze the design features and recommendations for its installation.

Device

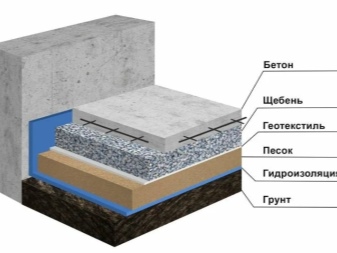

Concrete blind areas are characterized by structural simplicity, and the materials described below will be needed for self-production.

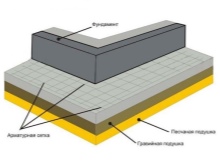

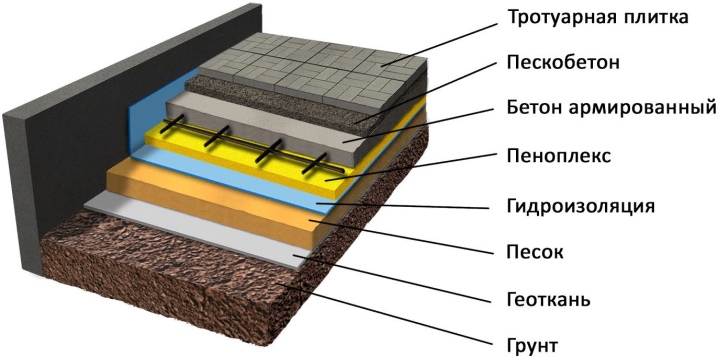

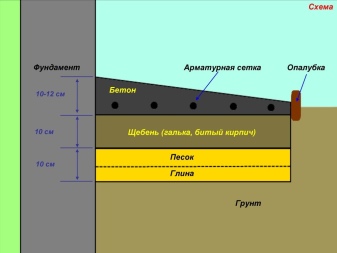

- Pillow (cake). It is necessary to backfill before pouring the solution into the structural grooves. This role is often played by sand (coarse and medium grain size), crushed stone, gravel of the smallest diameter, or a mixture of gravel and sand. If fine sand is used as a substrate, large shrinkage can occur. Due to strong shrinkage, the structure may crack. The most reliable option is a bedding of two layers: first, crushed stone or gravel is poured, which compact the soil, and then sand is poured.

- Reinforcement laying. Reinforcement mesh in the structure provides additional strength. The dimensions of the grooves usually vary - either 30 by 30 cm or a perimeter of 50 by 50 cm. The diameter of the reinforcement is 6-8 mm, however, everything is based on the type of soil.

- Formwork. The structure must be supplemented with guides made of straight boards. The formwork is installed over the entire coverage area. The width of the guides is 20-25 mm. The formwork allows you to eliminate the spreading of the composition.

- Concrete mortar. The creation of a structure requires the use of concrete of a special composition.

The brand of the solution is selected separately, since the strength, evenness and durability of blind area structures are added from the type of mixture and its introductory qualities. For this type of buildings, a mixture of M200 is often used. The strength class should start from the B15 indicator (brands of other high values can also become an analogue). It is worth taking into account such characteristics as resistance to frost (the ideal indicator for this parameter is F50). In order for the blind area to have the best indicators of resistance to temperature changes, it is worth choosing solutions with an F100 indicator. Self-construction of the blind area is acceptable both in terms of profit and in terms of price.

Composition and preparation of concrete

To create a blind area around the building, it is not necessary to purchase a ready-made mixture or order a concrete mixer rental. You can do everything yourself if you calculate the proportions of the constituent materials. You can mix the M200 concreting mortar yourself. Consider the recipe:

- 1 part of the cement composition (the best option is Portland cement in gradation 400);

- aggregate in a proportion of 4 parts (crushed stone or gravel is suitable);

- sand of medium or fine grain size should be 3 parts;

- the liquid is ½ part of the solution.

This means that to obtain 1 m³ you need:

- cement about 280 kg;

- sand about 800 kg;

- crushed stone will need about 1100 kg;

- liquids - 190 l.

Advice: first mix the liquid and cement powder, mix until smooth, and only then add gravel and sand.

To ensure extra strength, certain rules must be followed.

Construction requirements

Everything you need to know about creating a blind area contains SNiP. Here you can find all sorts of recommendations and general rules.

- The total length of the blind area must be 20 cm higher than the length of the roof overhang. If there is a drain in the design, then such indicators are also important to take into account. The best value in this case is a length of 1 meter. It is these indicators that make it possible, on occasion, to put a tiled path near the structure.

- The depth of the strip structure is calculated at half the index of the depth of soil freezing.

- The length of the blind area structure must correspond to the perimeter of the house. However, some gap is observed when installing the porch.

- The thickness is also regulated and is approximately 7-10 cm, calculated for the top layers. However, in addition to the blind area, parking lots are often created. In the manufacture of parking, the thickness of the blind area increases and is up to 15 cm.

- Bias. The slope, in accordance with general requirements, is from 1 to 10 cm per meter of structure. The most common indicators are 2-3 cm, which is approximately 3 degrees. The corners are directed towards the opposite side of the foundation. It is no longer worth making a slope, as it will be impossible to walk on a too "steep" track in winter. Ice build-up can cause accidents.

- Installation of the curb. Although the blind area does not at all involve laying a curb, such a possibility exists. It is better to install curb ceilings if shrubs or trees grow around the perimeter of the house, the roots of which tend to grow strongly. These are plants such as raspberries, poplar, blackberries, etc.

- Optimum base / plinth height. If hard coverings are used, the base / plinth height is above 50 cm.

- The best indicator of the "elevation" of the blind area above the soil surface is 5 cm or more.

There are several drawings and diagrams that regulate the construction of a crushed stone blind area. The structure is erected from a solid concrete layer. The option is relevant both for ordinary soil and for "problem" varieties.

If you follow the recommendations of SNiP, then even on your own you can build an ideal blind area on the area of a country house.

What is required?

To start building a high-quality blind area, you may need:

- sturdy pickaxe;

- long twine;

- regular roulette;

- marking pegs;

- concrete composition;

- rammer;

- a film that does not allow moisture to pass through (geotextile);

- boards for the construction of formwork;

- level;

- hacksaw;

- reinforcement material;

- nippers, nails and welding machine;

- a sealing compound (they will need to process the seams, you can use a polyurethane-based product);

- spatula, trowel and rule.

DIY manufacturing technology

The technology for the construction of such structures involves several stages. Each of the stages is quite simple, having step-by-step instructions at hand, even an inexperienced builder can handle them.

Markup

First, you should prepare the site. It is necessary to mark the tape structure. You can use pegs for this. But in this regard, there are several tips.

- A distance of one and a half meters is observed between the pegs.

- The depth of the dug trenches directly depends on the type of soil. The minimum depth is approximately from 0.15 to 0.2 m. If the work is carried out on heaving soil, we increase the depth (0.3 meters).

The markup is greatly simplified if you perform it in the following steps.

- We drive in pegs in the corners of the building.

- We install beacons between the main pegs of the circle of the house.

- We pull on the lace and combine the pegs into a single structure.

At this stage, the craftsmen recommend using a sealing compound to separate the foundation and protective coating. Then you can create the slope of the structure. For this, a trench is dug, where the depth of the first part is greater than the other.

You can use wood for ramming. The log is placed vertically, raised. Then we lower the log down with force, due to which the bottom is compacted.

Formwork creation

For the construction of the formwork, boards will be needed. Immediately you need to mark the height of the pillow being created. At the corners, the box is fastened with metal parts. If you do not want to disassemble the formwork after the completion of the work, then it is better to pre-treat the wood with an antiseptic and wrap the boards in roofing material.

Arrangement of a pillow

In order for the blind area to be built according to the necessary standards, you should start preparing the foundation for it first. The base can be either clay or sandy. The thickness of the sand layer is up to 20 cm. It is best to lay the pillow not in one layer, but in several. Each layer must be tamped. As a result, you need to level the drying solution.

Waterproofing

Waterproofing is done by laying roofing material or other similar material in several layers. Waterproofing experts advise the following.

- To obtain an expansion joint, the material should be slightly "turned" against the wall.

- Roofing material or its analogue fit directly overlap.

- If the installation of a drainage structure is planned, then it should be installed close to the resulting "water seal".

Reinforcement, pouring and drying

From the layer of gravel we lay a metal net above a level of 3 cm. The step is approximately 0.75 m. Then we knead the concrete mixture and fill it in equal portions in the formwork section. The layer of the mixture should be equal to the edge of the plank box.

After pouring the solution, it is worth piercing the drying surface in several places. Thanks to this, excess air will come out of the structure. For proper distribution of the mixture, you can use a trowel or a rule. It is possible to increase the resistance of concrete by means of surface galling. To do this, it is covered with dry PC 400 in a thickness of 3-7 mm. This should be done 2 hours after pouring.

To avoid cracking of the composition, the masters recommend sprinkling it with water several times a day. In order to properly fill the blind area, it is important that cracks do not go over the concrete.

A plastic wrap will help protect the coating from moisture precipitation. It is believed that the concrete surfaces of the blind area dry already for 10-14 days. However, the regulations require you to wait 28 days.

How to cover?

The width, as well as the density of filling the expansion and expansion joints with the waterproofing material, must be controlled. Repairs may be required from time to time. Vinyl tapes up to 15 mm thick work well for expansion joints.

If work is carried out on heaving soils, the blind area is not connected to the base. In this case, drainage and storm drainage are erected around the circumference of the building, thanks to which water will be diverted from the building. Special techniques help to increase the tightness of concrete structures and provide protection against collapse. Impregnation can help with:

- cement mixture;

- liquid glass;

- primers (the material must assume deep penetration);

- water repellent.

The blind area can be refined by decorating with "torn" or smooth stone, tiles, pebbles. Decor elements are attached to concrete.

Blind area repair tips

Small chips can be repaired and cracks can be repaired with concrete or cement mortars. It is better to repair minor flaws either in early autumn or late spring. The weather during the work should be clear and dry. Repairs are best carried out at a temperature of 12-10 C.This is necessary so that concrete surfaces do not take on excess water, do not get damp, do not collapse or crumble under the influence of precipitation or heat.

If repairs have to be carried out in extreme heat, it is better to choose the time of sunrise or sunset. At dawn and late in the evening, the effects of heat on the surface are minimal. When carrying out work, it is important to understand that the fresh layer of the future blind area must be covered with plywood, it should not be located in direct sunlight. Under the sun, water evaporates too quickly from the solution, and its strength and quality properties decrease.

Chips, small cracks and cavities can be corrected by using a mastic from a bituminous component or a cement-sand mixture. Mixtures of these funds are also relevant. If you plan to repair deep potholes and large chips, you need to join the damage before work. You can eliminate small damage by performing work in the following sequence.

- First you need to clean all surfaces. After that, we carefully examine all the damage and evaluate it, then we can decide how to fix the flaw.

- Surface cracks or chips are treated with a primer several times. After putting in several layers of primer, you can use a cement-sand mixture. The proportions are simple: we take 2 parts of sand and 1 cement powder. It is necessary to grout with a spatula, observing the approximate slope. Grouting is carried out 10-30 minutes after applying the solution. Grouting is done with a trowel and dry cement.

- To fix more serious flaws, preliminary jointing of the damage is carried out. For these purposes, it is recommended to use hand tools or an electrical equivalent. An increase in the flaw area is inherent in joining. A wedge-shaped depression should form at the site of the damage. The area is then thoroughly cleaned. When grouting, you can use a material consisting of slag, a small amount of asbestos and a bitumen composition. Bitumen is taken 6-8 parts with 1.5 - 1 part of slag. Asbestos needs to be added 1-2 parts. After pouring, sand is poured onto the surface. Then everything should dry well. A mastic sealant may also be needed.

The damaged layers are eliminated, and then new ones are poured. The situation changes if the repair is carried out in areas without concrete or with partially cracked concrete. In this case, it will be necessary to prepare the blind area and lay a new concrete layer.

If the surface to be poured is small, you can knead the solution yourself. With a large amount of work, it is better to work with a concrete mixer. The solution is made up of the proportions of crushed stone and sand in the composition of 1/5 or 5 / 3.5.

It is best to use cement of extremely high grades (sand concrete not lower than M 300). The ideal option would be to use washed river sand (diameter - maximum 0.3 mm). Crushed stone should be taken not very large, with the diameter of individual particles not exceeding 30-40 mm.

Before work, you need to carefully clean the area. Leaves, twigs, or dust shouldn't get in the way. Further along the edge, where there is no concrete layer, we put the formwork. Old boards are suitable as materials for formwork. We make an impromptu shield from the boards.

It is better to mix a new layer of mortar in a concrete mixer. If there is no old insulation on the plinth, you can create it yourself. This will require material in rolls or coating compounds. At the end of the repair work, before the direct restoration of the blind area, it is necessary to find out the size of the pouring distances of the new layer.

If the value is 3 meters or more, then an expansion joint must be placed. The seam is created using boards (thickness is about 20-25 mm), as well as bitumen mastic. After that, you can proceed to the fill. It is better to mix the mass of concrete in several passes. The components must be fed gradually, dividing the materials according to the proportions of parts.

How to make a blind area of concrete, see the video below.

The comment was sent successfully.