How to fix drywall to the wall?

Today drywall is rightfully recognized as one of the most popular and demanded materials. This is due to its affordability and undeniable ease of use. It is very often referred to for leveling the floors in the house. Today we will talk about how you can attach drywall to the walls, as well as get acquainted with all the pros and cons of this common finishing material.

What it is?

Before embarking on the study of such a finishing material as drywall, it is worth figuring out what it is.

Drywall is a finishing material that consists of two layers of cardboard with hard plaster and special fillers inside. It is used for a wide variety of purposes. For various jobs, sheets are produced with different thicknesses. Plasterboard panels can be laid not only on walls, but also on the floor or ceiling. The main thing is to choose the materials of the appropriate category.

Peculiarities

Today, in stores of building and finishing materials, you can find absolutely any product for any repair work. For leveling the walls, customers are offered high-quality putties, plasters and other practical compounds. However, many people choose "dry" material for such works - drywall.

Today, the problem of uneven walls is familiar to many. It is faced by both the owners of private houses and city apartments. However, it is quite possible to make the floors even on your own, without involving a team of finishers.

Uneven floors are bad not only because they look unpresentable, but also because many finishing materials cannot be applied to them. These include tiles, most types of paints and wallpapers. On the basis with drops and potholes, such coatings do not hold reliably, and they look very sloppy. Many of the finishing materials do emphasize irregularities on the walls.

In such cases, you cannot do without a perfectly flat and smooth drywall. After its installation, the walls acquire a more aesthetic and neat look. In addition, sheets of this popular material are extremely easy to process and can be coated with almost any canvas and paints.

Plasterboard sheets are attached to the wall using a special wooden or metal frame. There is also a frameless installation method, which experts consider more complicated.

When choosing one or another installation method, it should be borne in mind that you need to work with drywall carefully. This is due to its peculiarity, which is fragility and the possibility of crumbling. If you accidentally damage the drywall, then it is unlikely that it will be possible to return it to its original appearance. That is why, for the manufacture of, for example, arched structures, ordinary drywall is not suitable, since with slight bending it will simply break.

Another distinguishing quality of drywall is its multitasking ability. It is used not only for leveling different bases, but also for the manufacture of interesting multi-level ceilings, shelves with shelves, niches and cabinets. This once again confirms the unpretentiousness of this material and the ease of working with it.

Advantages and disadvantages

Like any other finishing material, drywall has advantages and disadvantages that you should be aware of if you decide to install it on the walls in your home.

First, let's take a look at the list of positive qualities of drywall sheets:

- They are distinguished by a flat and smooth surface, because of which they are chosen for leveling various substrates.

- The advantage of drywall is its thermal conductivity. The room where the walls are sheathed with this material will always be warm and cozy.

- Drywall is recognized as an environmentally friendly material. It contains no hazardous and harmful substances, so it can be safely used even in the decoration of children's rooms.

- GKL sheets are fireproof and do not support combustion.

- Another significant advantage of drywall is its vapor permeability. Thanks to this quality, such material is not susceptible to the formation of mold and mildew.

- Often, consumers buy exactly drywall, since it has an affordable price, and is used for a variety of purposes.

- Plasterboard walls can be supplemented with various insulation materials (often they prefer foam and mineral wool).

- Working with drywall is fairly straightforward. To do this, you do not need to purchase expensive tools.

- Using this finishing material, you can bring to life any bold design ideas. That is why drywall is used by many designers in their designs.

- Drywall does not require expensive and regular maintenance.

- No unpleasant chemical odor emanates from GLA.

- It handles seamlessly. To do this, you can use almost any material, from ordinary paper wallpaper to tiles.

- Plasterboard sheets can be installed in any room. This can be not only a dry living room or bedroom, but also a bathroom or kitchen. Of course, for the latter, it is necessary to select moisture-resistant canvases.

- Thanks to gypsum sheets, you can hide unattractive communications and wires in the room.

- With the frame method of fastening drywall, the rough walls do not need to be prepared for a long time and meticulously with the help of special compounds. It is enough to treat them with antiseptic agents to avoid the multiplication of harmful microorganisms.

- Many consumers purchase drywall for repair, because it can be used immediately after purchase, allowing them to lie down for 2-3 days without subjecting additional preparation.

- Today, the choice of drywall sheets allows you to choose the best option for any conditions.

As you can see, the list of positive qualities of drywall is quite impressive.

However, it also has its weaknesses:

- Plasterboard is not recommended for installation in rooms with high humidity levels. For such conditions, it is worth choosing exclusively moisture-resistant types of material. However, according to experts, even such drywall in humid conditions begins to lose its properties and deteriorate.

- Drywall sheets can begin to crumble, especially under heavy loads. That is why it is not allowed to hang heavy objects such as large clocks, hanging sinks in the bathroom, lighting fixtures, large paintings and other objects of considerable weight on gypsum walls. Otherwise, these things will not stay in their places for long, and then they will simply fall off and damage the drywall.

- You need to work with drywall very carefully so as not to damage it. Do not fold this material unless it is arched.

- Drywall on the frame will "eat up" some space in the room, so this method of installing the material is not suitable for all areas.

How significant are the listed disadvantages - each consumer must decide for himself. But it is worth noting that many problems can be avoided if you choose the right material and strictly adhere to the instructions when attaching it to the walls.

Materials and tools

If you decide to independently install drywall on the partitions in your home, then you should stock up on tools and materials.

From the toolkit you will need:

- special knife for cutting drywall sheets;

- special glue (for frameless mounting method);

- a building level, a plumb line, a special marking cord, a tape measure, a long ruler (you can take a rule instead), a pencil / marker - you will need these tools to mark the walls and to correctly control the verticality of surfaces;

- normal and rubber hammers;

- spatula (you can take a trowel instead);

- a separate container for mixing the adhesive;

- screwdriver;

- puncher;

- self-tapping screws;

- dowels;

- screws;

- electric drill with mixer attachment;

- long-handled roller;

- soft brush;

- plane (needed to cut a chamfer);

- putty (for applying a finishing layer after all work).

From the materials you will need:

- GKL sheets (ordinary, moisture-resistant or fire-resistant - it all depends on the room in which the sheets are planned to be installed);

- galvanized profile or wooden beam (to form a frame with an appropriate installation method).

Application area

Drywall is a versatile material. It is used in a wide variety of conditions and fixes seamlessly on a variety of substrates.

You simply cannot do without this material when it comes to a wooden house or a log building. In such conditions, the walls are almost always uneven and require proper alignment. However, it should be borne in mind that wooden houses always shrink and drywall boards can be installed in them only after the completion of this process. Otherwise, the sheets may be damaged or deformed under such conditions.

To install drywall on walls in wooden houses, you must:

- provide space for the installation of insulation (if, of course, you plan to additionally insulate the room);

- have free space for laying communication systems.

Aligning walls in wooden houses is not easy. In this case, frame installation will be the best option. However, some owners first attach sheets of plywood or chipboard to boards and bars, and then glue drywall onto them.

Drywall can also be attached to walls with a concrete base. For such surfaces, it is not at all necessary to make a complex frame. Drywall can be glued to such substrates using special glue. Such adhesives are very common in stores today. For example, the high-quality composition "Perlfix" is offered by the well-known company Knauf.

Drywall is often used to level brick walls. Here you can also refer to the usual gluing of the material without making the frame. In such cases, immediately before installation, it is necessary to find out with the help of a level how curved the floors are, after which any dirt, dust and greasy stains are removed from the brick. In addition, the brick wall must be completely dry, otherwise sufficient adhesion to the drywall cannot be achieved even with the use of high-quality glue.

In case you want to align the walls of foam blocks, then you should turn to the frame installation method. This is due to the softness of such grounds. However, some users turn to frameless installation, but before that, the foam block must be prepared - finished with soil or plaster.

Aerated concrete walls also often require leveling. In such cases, you can use both frame and frameless mounting methods. In the second case, it is necessary to treat aerated concrete bases with a deep penetration primer. In such cases, the glue must be selected especially carefully, as in cases with overlappings from foam blocks. Experts recommend using formulations from Knauf and Volma Montazh.

Drywall will be able to make the walls even, even in adobe houses. Such structures are full-fledged composites built from clay, earth, straw and sand. Of course, with such building materials, there is no need to talk about ideally even partitions. For this reason, leveling sheets such as drywall are simply necessary in them.

Mounting methods

We have already mentioned above that gypsum plasterboards are attached to the walls by making a frame or frameless. The choice of one or another installation option largely depends on the structure and conditions of the room and, of course, the preferences of the owners.

On profile

This type of drywall installation is the most popular. It is quite possible to make it yourself. With this method, gypsum sheets are installed on a pre-prepared frame, consisting of metal profiles fixed along the wall.

It is worth considering some of the nuances of this common installation method:

- Insulation can be placed between the wall and the profile, if necessary. Most often, consumers choose mineral wool, penoplex or polystyrene for this. However, we must not forget that the rough walls must be treated with an antiseptic composition before laying the insulating layer.

- Various engineering communications can be hidden in the cavity behind the frame. These can be water pipes, radiators, or electrical wiring.

- Do not forget that in rooms with a high level of humidity, it is permissible to use only moisture-resistant drywall. Ordinary sheets in such conditions will not last long.

Mounting drywall sheets on a frame has a number of advantages:

- with such an installation, additional noise and heat insulation is provided in the room;

- frame installation allows you to align even ugly curved walls;

- before installing the frame and fixing the drywall, the rough partitions do not require preparation (it is enough to walk on them with antiseptics).

Let's take a closer look at the step-by-step instructions for installing drywall on the frame:

- First, you need to measure the walls and make markings on them for the installation of metal profiles and suspensions.

- The layout for the guides must be started from the top profile. In this case, the necessary indent is made from the overlap, then a line is drawn and with the help of a plumb line it is transferred to the floor.

- The vertical profiles must be spaced at least 60 cm apart. In this case, it is necessary to ensure that each plasterboard sheet rests on three racks.

- As for the installation of suspensions, here it is also necessary to maintain a certain distance - 60-80 cm will be quite enough.

- After that, you can proceed directly to the installation of the frame. First, along the perimeter, you need to fix the guide profiles. To screw them to the ceiling and floor, you must use a hammer drill, dowels and screws.

- At the points marked during the measurements, the suspensions must be attached.

- Carriers should be inserted into the guide profiles and secured with hangers.

- Fasten all the details as securely and tightly as possible, since the durability and strength of the entire structure as a whole will depend on the quality of the frame.

- Before installing drywall sheets, it is necessary to strengthen the horizontal guides.

- When the frame is ready, you should proceed to installing drywall sheets on it. They must be fixed in an upright position. To do this, you can use special metal screws 25 mm. But they need to be screwed in such a way that the caps are slightly "recessed" into the drywall.

- After installing all sheets, the joints between them must be treated with putty using a reinforcing tape.

- When the putty is completely dry, the drywall attached to the frame should be completely putty. After that, the surface of the wall decoration will be perfectly flat and smooth (without any flaws).

According to experts, this installation technology is simpler. However, it should be borne in mind that such a design will take away part of the area in the room, therefore, in a very small room, it is better to use a frameless method, if, of course, overlapping allows this.

Profile-free constructions

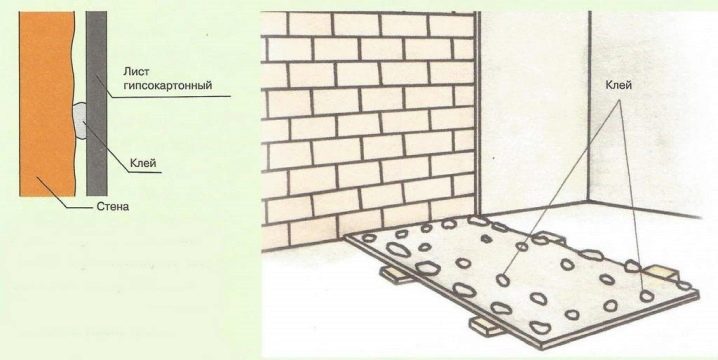

Frameless drywall fastening is called glue in another way, since with it the sheets are fixed on the ceilings using a special adhesive.

Choosing this installation option, you need to comply with the following conditions:

- there should be no mold or mildew on the rough floors;

- there should also be no crumbling areas;

- walls should not be exposed to freezing;

- they must be protected from dampness and excess moisture;

- it is necessary to remove old finishing materials from the surface of the walls, as well as dust, dirt and any other contamination.

Frameless drywall fasteners can only be used if the curvature of the walls does not exceed 4 cm. Otherwise, it is better to build a profile frame.

You can glue drywall to the base in different ways.

The best option must be chosen based on the technical condition of the floors:

- The first mounting method is designed for smoother surfaces. With it, the fixing of plasterboard sheets occurs directly on the wall using mounting gypsum glue. It is transferred to the base along the perimeter (longitudinal lines).

- If the floors have irregularities on their surface, then it is recommended to glue the drywall onto them using Perlfix glue. It must be applied in portions along the entire length of the reverse side of the gypsum sheet (maintain a distance of 35 cm between the piles of glue), as well as along its perimeter.

Now it is worth considering in more detail the instructions for the non-profile installation of drywall sheets:

- First, you need to measure the floors and plan the placement of drywall boards.

- Then it is necessary to competently prepare the surface of the base. If the wall has a porous structure, then it should be covered with a primer mixture.

- Now you need to cut out the sheets of gypsum board, since not only whole panels, but also prepared inserts will be useful to you.

- To make a straight cut, it is best to use a sharp construction knife. If you are going to make curved cuts, then you should use an electric jigsaw.

- Prepare the glue. To do this, you can use modern gypsum solutions, which harden for a long time.

- If the glue dries too quickly and you want to extend its drying time, then add wallpaper adhesive or good old PVA to the dilution water.

- Now you can start gluing drywall to the walls. Pay attention to the thickness of the adhesive. It directly depends on the area of irregularities on the base. If the overlap is sufficiently even, then the mixture can be applied to it immediately.

- To eliminate significant curvature, beacons should be installed. They can be built from plasterboard strips with a width of 10 cm. These elements must be glued along the entire perimeter in a vertical position, maintaining a step of 40-50 cm.

- Right and left beacons (extreme) should be mounted using a plumb line.

- After that, focusing on the mounting line (or thread) stretched between the extreme beacons, you need to install the remaining strips.

- Line up the beacons with the rule.

- Plasterboards must be pressed using the rule set in the various positions. Tap the panels with a rubber mallet and correct their position.

- When the glue is dry, the seams between the drywall panels must be finished with putty.

Tips & Tricks

Drywall is a lifeline for wall alignment. Installation of gypsum sheets cannot be called unbearably difficult and energy-consuming.

To give you a more aesthetic and reliable design, Consider the following tips and tricks from professionals:

- Installation of gypsum plasterboards in the room is permissible only after laying the flooring. Also, by the time of leveling the floors in the room, all issues regarding the laying of communications and heating systems must be resolved.

- When gluing drywall (with a frameless method), try to avoid cross-shaped joints. It is better to lay out sheets with an offset.

- Pay attention to the width of the gaps between the gypsum sheets for non-profile installation. This indicator should be from 5 to 7 mm, the gap from the floor - 7-10 mm, and from the ceiling - 3-5 mm.

- In order for the drywall to reliably hold onto the floors, it is necessary to pay attention to their technical condition. There should be no crumbling or crumbling areas in the walls.

- With the frame installation method, it is recommended to create a chamfer on the cut material (it is needed for better sealing of all the seams of the finish). For this, it is recommended to use a special edge planer.

- It is recommended to prepare all tools and materials before starting installation work. This will allow you to work without distraction or wasting time on unnecessary actions.

- Adhesives must be diluted, based on the instructions. It should be printed on the packaging.

- Do not overtighten fasteners on drywall as this can deform the fragile material.

- To work with drywall, you need a level. Of course, you can choose the tool that is more convenient for you to work with, but experts advise turning to laser devices.

- Pay attention to temperature conditions during installation work. The recommended temperature is +10 degrees. If the room is noticeably cooler, then you should take care of additional heating systems in advance.

- It is recommended to install gypsum plasterboards on the walls not immediately after purchase, but after it has been lying in your house for 2-3 days in dry and warm conditions.

- Whichever method of installation you choose, at the end the joints must be insulated with reinforcing tape. Only after that you can proceed to puttying the seams and caps of the self-tapping screws.

- Don't forget the holes in the drywall for sockets and switches. They can be cut with special metal scissors. This work should be done before assembling the sheets.

For information on how to attach drywall to the wall, see the next video.

The comment was sent successfully.