Everything you need to know about clear plexiglass

Plexiglass is a common material that is widely used in construction, medicine, mechanical engineering and even interior design. The market offers a wide selection of organic glass in any size, so you can choose the product yourself by studying the technical features and advantages. This material is regularly used in the manufacture of furniture, watches and various appliances.

Peculiarities

Plexiglas belongs to the category of environmentally friendly and safe materials. It is lightweight, it can be easily given any shape, while the optical properties will not be disturbed. In terms of technical specifications, it should be noted that the material can be processed using equipment such as saws, routers and grinders. High thermoplasticity allows the use of plexiglass in different areas. The material is durable and also has a number of advantages.

Compared to ordinary glass, sheet organic material is more durable, it is not so easy to break, therefore many things today are made from it. The material lends itself to processing, it is possible to create products of any shape from it, therefore it can often be found in furniture structures and other interior items. Due to its low weight, the transportation process is simplified, the same can be attributed to the ease of installation.

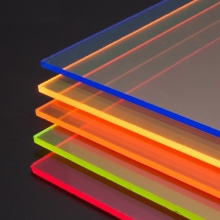

The degree of transparency of plexiglass is high, it can be combined with pigments of different colors, obtaining an original effect, which is actively used by many designers. In terms of resistance to chemical attack and temperature extremes, organic glass cannot maintain its integrity under such conditions. It is necessary to take care of products made of such material carefully, using products that do not contain acetone or alcohol for processing. Despite such minor disadvantages, acrylic plexiglass has many more advantages, which allows it to be used by manufacturers of various products and designs.

Applications

In mechanical engineering, plexiglass is a valuable material that can be installed on various devices. For the production of ships of any size, such a product is used as glazing and internal partitions. In the construction of architectural structures, plexiglass is a popular component, since it can be used to make structural elements, partitions, awnings and much more.

As for the interior use, it should be noted here that the designers especially fell in love with plexiglass, from which you can create stunning designs, original lamps, extraordinary aquariums and beautiful stained glass windows. A Due to its flexibility, plexiglass can be shaped into any shape for decorating rooms, including hemisphere, cubes and many others.

Plumbing from such material is also in great demand; tables and other furniture can be made of plexiglass.

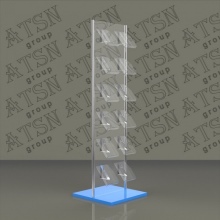

Advertising products, in particular, outdoor structures, stands, stands, exhibition and trade equipment are often made of plexiglass. This material is also used for the production of contact lenses and safety glasses, the same applies to medical instruments, without which endoscopic operations cannot do.

It is safe to say that organic glass has firmly entered the life of people, and it can be found almost everywhere.

Due to its excellent characteristics, the scope of application of the material is quite extensive.

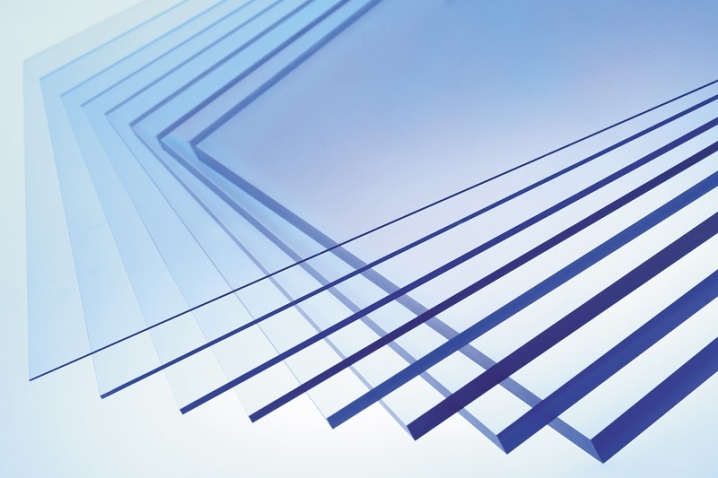

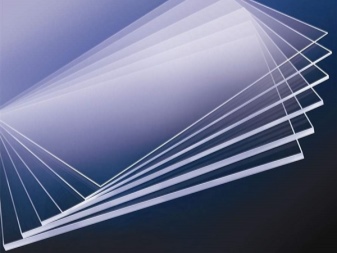

Overview of types and sizes of sheets

Plexiglass sheets are offered on the market in different sizes, and this indicator affects the flexibility, strength and other characteristics of the material. Parameters of 2050x3050 mm with a thickness of 1.5 mm are considered standard, the weight of one such element is about 11 kilograms. This thickness is suitable for the production of advertising structures, business card holders, booklet holders, besides, the raw material is very flexible and it is easy to create the desired shape from it.

The material is 2 mm thick, used for the manufacture of protective screens in paintings and photographs. Acrylic sheet 3 mm is produced in a dairy version, therefore it is often suitable for illuminated advertising products. As for transparent plexiglass with this thickness, it is used for the manufacture of windshields in motorcycles.

If a material with greater strength is required, where flexibility does not matter, you can pay attention to 4 mm, 5 mm, 6 mm, 8 mm and 10 mm plexiglass sheets. Some products are produced in the size of 1525x1025x4 mm.

As for the varieties, plexiglass is divided into matte, transparent and translucent, and each of the options on the market has its own characteristics and features.

Matt plexiglass is created using special technology and additives. For production, casting or extrusion can be used. If a glossy matte surface is required, chemicals are added to the composition that reduce transparency, while you can give the desired color to the starting material. To achieve an anti-glare effect, manufacturers use an injection molding method. On both sides of the mold, a micro-mesh of the pattern is applied, whereby a satin-finished surface is created.

Transparent smooth acrylic glass is a sheet material with a perfectly flat surface, which has a strong gloss. The objects displayed in it are not distorted, and the contours will be just as clear. It is worth noting that the color characteristics can be either bright or muted.

On the market you can find extrusion red, blue, green, yellow glass in different shades, which allows you to choose the perfect design solution.

A glossy dairy product is characterized by low transparency and, in some versions, may not transmit light at all. The surface is smooth on both sides, has an ideal gloss, while the shape is not resistant to mechanical damage, so fingerprints, scratches and chips easily remain on such a coating.

Another type of plexiglass is satin, which is characterized by the presence of roughness, which makes it translucent. If you use a magnifying device, you can see microscopic defects through which the refraction and diffusion of light occurs. Any matte plexiglass is available in a variety of colors, since special dyes can be added to the composition.

Corrugated plexiglass has a series of ridges and depressions on the surface. It is this "defect" that creates the pattern, allowing you to mask scratches, minor mechanical damage, so it looks presentable for a long time.

How to make plexiglass transparent?

If a plexiglass product has been used for a long time, it probably has lost its former appearance, but this does not mean that it needs to be thrown away. To clean it from cloudiness, you just need to study the recommendations of specialists, as well as follow the instructions - then the surface will become almost like new.

One of the most common methods is polishing. For this, it is better to use GOI paste, which is easy to find in any hardware or hardware store. However, there are other types of polishing pastes on the market, so you can try them.

This method will allow you to restore plexiglass only in cases where there are no deep scratches on it.

To get rid of serious mechanical damage and return presentability, you need to explore other methods of updating plexiglass products. Oddly enough, ordinary clear nail polish can help to cope with this problem. This is an affordable option that does not require money and a lot of time.... With such a simple device, you can return the plexiglass to its former appearance as soon as it dries. At the same time, it is important to ensure that bubbles do not form in the thickness of the varnish, and for this you should not use a hairdryer or other devices to accelerate drying.

After that, you will need to polish the surface with medium-hard sandpaper until it becomes cloudy, and then go to No. 0 paper, which will remove minor scratches. To restore transparency, you need to use a felt cloth together with GOI paste - and the glass will become perfect again.

If there are a lot of scratches on the surface, it must be cleaned and then treated with dichloroethane. This product dissolves plexiglass, which in a thick form flows into cracks and seals all defective spots. After everything is dry, you need to polish it as described above. Dichloroethane is poisonous, so first you need to make sure that the room is well ventilated and that your hands are protected. Good luck!

You can learn how to polish plexiglass at home from the video below.

The comment was sent successfully.