What is plexiglass and where is it used?

Decorative crafts, jewelry, dishes, wall and floor decoration made of transparent plastic can be found everywhere. Sometimes we even confuse it with real glass, although it is plexiglass, without which it is difficult to imagine the modern world. It is worth learning more about this wonderful material, which is so in demand in all areas of our life.

What it is?

Plexiglass is often called plexiglass, and its basic composition, indeed, coincides with the composition of this material. However, the brand's manufacturers have developed special auxiliary components, thanks to which the popular plastic has acquired many useful properties that make it a popular, widely used product.

The distinctive characteristics of the product are due to its physical properties:

- immunity to the action of sunlight, no discoloration and yellowing;

- higher strength than quartz glass;

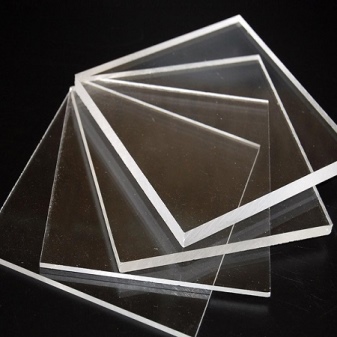

- high light transmission and ability to save heat due to low thermal conductivity;

- resistance to microorganisms, aggressive chemistry, high temperature range, moisture;

- lightness compared to ordinary glass with a minimum layer of 1 mm (the weight of 1 sq. m is only 1.2 kg);

- when burning, plexiglass products do not emit harmful vapors, and when damaged, the material does not form dangerous sharp fragments;

- the polymer is easy to cut and give it any desired shape;

- the material is hygienic, does not require complex maintenance, due to the fact that its surface is smooth, and dirt and dust particles do not accumulate on it.

At the same time, this excellent synthetic material has several drawbacks: products made from it are susceptible to external damage, and also light up easily.

What is included?

Plexiglass is an environmentally friendly product based on polymethyl methacrylate. Its other name is acrylic, and it belongs to the type of artificial organic plastics. The basis of the material is thermoplastic acrylic resins, more precisely, one or more derivatives of a carboxylic monobasic acid. These are components that transmit light well.

The chemical formula of acrylic is the same as that of plexiglass - (C5O2H8) n, but in addition, it contains many additives that give the thermoplastic structure special properties, such as hardness, flexibility, resistance to mechanical stress and damage, as well as pigments required to obtain a specific color.

Views

There are currently two types of material.

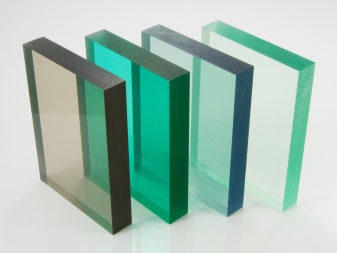

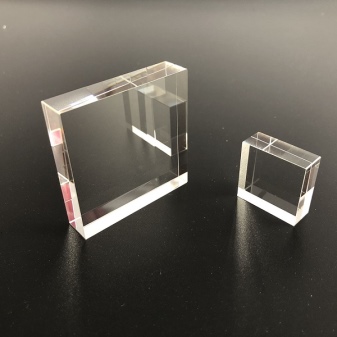

- Plexiglas XT - these products are manufactured using an extruder. Under pressure, methyl methacrylate passes through the forming tool of the equipment, and from the melt products are obtained in the form of solid panels with a thickness of not more than 25 mm, as well as rods, rounded profiles, sheets with a wavy and reflective surface. Such plastic has increased elasticity and flexibility, it is easier to transform it into different shapes, but at high temperatures it shrinks slightly, and its strength leaves much to be desired.

- Cast acrylic glass is considered more durable. Plexiglas GSobtained by polymerization at the stage of forming an acrylic preform under the influence of an activator. During this chemical process, the glass molecules are built into strong, long chains, thus maximizing the strength of the product.Its common forms are pipes, blocks with different thicknesses, monolithic sheets that are resistant to deformation and aggressive environments. But the flexibility of this species is much lower than that of the extrusion version.

In general, acrylic glass has increased impact strength, 5 times higher than that of ordinary glass.

Decorative possibilities

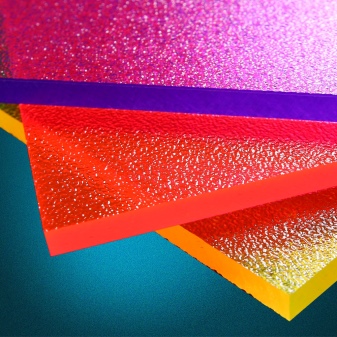

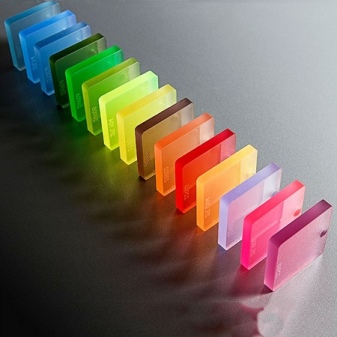

The variety of colors, textures and luster is the main feature of organic glass, which opens up wide possibilities for its use.

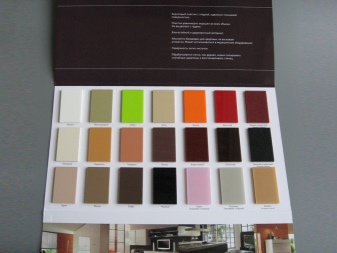

- The color palette of the material is not just huge - it is infinite, since the number of shades of any tone in varying degrees of intensity is infinite. However, the richer and deeper the color, the less transparent the glass becomes. It is appropriate to select various options for such products for countertops, kitchen and guest sets, for certain attributes of a bathroom or shower.

- Surface treatment also has a different effect, and depending on the idea, you can choose a variety of products.

- With a matte, satin surface, smooth, but with a subdued shine... They are suitable for decoration in a Scandinavian or minimalist style.

- Shiny, glossy panelsthat look bright and saturate the space with radiance.

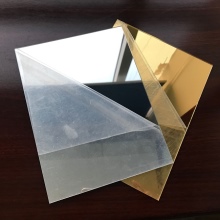

- Mirror-coated parts in silver or gold colors, the result is gorgeous reflective surfaces that rival genuine mirrors.

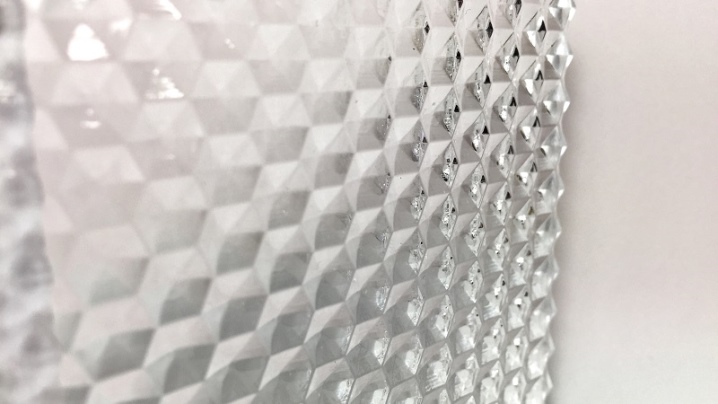

- By polishing, engraving and other surface treatment methods, you can achieve an unusual, beautiful texture of plastic sheets, but the most suitable material for this is colorless plexiglass, which is capable of transmitting light, but at the same time you cannot see anything behind it.

In short, the use of acrylic glass is limited only by our imagination, since the material has endless possibilities.

Comparison with other materials

Most often, plexiglass is compared to plexiglass. What's the difference? In fact, the choice is made between the same products that have an organic basis, however, there are different types of this material, and their parameters have significant differences.

Basically, the discrepancies in the properties of the material are associated with the methods of its manufacture. Products created by extrusion are less durable than injection molded. But do not forget that there are other varieties with their own specific characteristics.

- Shine material has a shiny surface and can be polished. And also it has a high level of moisture resistance.

- Honeycomb plexiglas Plexiglas SDP - two-layer. It is used for outdoor decoration due to its high impact resistance and immunity to external influences.

- Most plastics are vulnerable to damage but acrylic SatinGlass not prone to scratches.

- There are materials that differ smooth, velvety texture, the presence of a fluorescent effect and a metallic sheen.

It is no longer a question of differences, but of the purpose of the choice and the conformity of a particular material to it. As for comparing plexiglass with ordinary quartz glass, even here it is impossible to talk about which products are better and which are worse. Crystal clear familiar glass is UV resistant, hermetically sealed and strong material... However, even with such a minus as fragility, it is not always possible to replace it with acrylic or something else.

In turn, the polymer does not break, leaving debris, but it also has disadvantages. Some of its types are destroyed under the influence of the sun, household cleaning products are capable of melting. On the other hand, despite all the advantages of quartz products, acrylic is gradually taking the leading position, and, of course, this is due to its flexibility, strength, durability, ease of processing and low price.

Applications

Glazing is not the only application of the material, which is transparent and colored, has the desired characteristics. Plexiglass can be used:

- for the creation of billboards, exhibition exhibits, decorative finishing of residential and public premises;

- a variety of colors and high operational qualities allow it to be used for the manufacture of items of home furniture, attributes required in trade establishments and cafes;

- a sheet of acrylic plastic is often used to obtain cladding details for building facades;

- a variety of household and decorative containers, ecosystems for growing plants and keeping fish, illuminated floors, roofs, shades for lighting fixtures, bathtubs are made of synthetic glass;

- plexiglass is relevant for the manufacture of jewelry - excellent amber is obtained from it, almost indistinguishable from the real one;

- in the field of ophthalmology, the product is used to create lenses that replace the lens of the eye when it becomes cloudy, in dentistry - for the manufacture of fillings and implants.

Decor elements from these products are voluminous and bright, can be decorated with engraving, gilding and silver due to the ease of processing. In the interior, plexiglass materials are used for the construction of original interior and zonal partitions and walls, from which spectacular shelves and racks, door and wall stained-glass windows and panels, steps of internal stairs are created. Transparent interior accessories are no less attractive, their area of application is facade decorations, glazing of furniture, decoration of shop windows, floor coverings.

Billets made of injection molded and extruded acrylics of various sizes are used by designers in their bold experiments to create an extraordinary style in apartments and private houses. Plastic products help to design windows outside the box, create interesting mosaics in the kitchen and bathroom space, use plexiglass for the manufacture of countertops from painted materials with a textured surface. Molded plastic glass allows you to decorate residential houses and city buildings, create a spectacular home interior and make it unique.

Many of the items that we use or admire on a daily basis are created from this amazing man-made material.

For how to quickly and accurately cut plexiglass, see the next video.

The comment was sent successfully.