All about matte plexiglass

Organic glass (or plexiglass) is a widespread and demanded material that is actively used in various fields. At the same time, not every person knows that today there are several varieties of organic glass. Today in our material we will talk in detail about the matte type, consider its distinctive features, advantages, disadvantages and areas of application.

What it is?

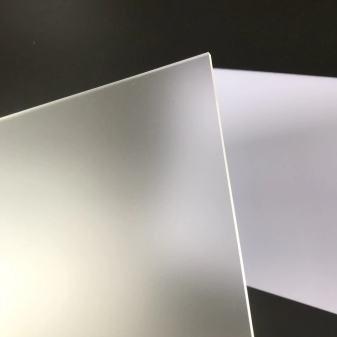

First of all, you need to decide what is matte plexiglass. Generally speaking, this material is a kind of ordinary organic glass. At the same time, a distinctive feature of the material is the fact that it has a rather limited ability to transmit light. So, depending on the specific category, the light transmittance of glass can vary from 25% to 75%. It is interesting. Popularly, frosted plexiglass is also called frosted plexiglass, acrylic glass or just acrylic. It is important to keep this in mind when purchasing material on the construction market.

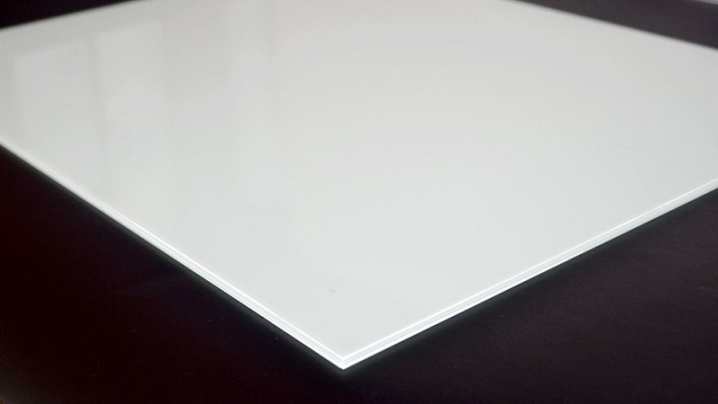

At its core, frosted organic glass is a sheet (usually white). The material is smooth to the touch. Also, with the naked eye, you can notice the fact that matte plexiglass has a shiny surface (and this characteristic of the material is characteristic of both the front and back sides).

The main feature of the material is that if you direct a stream of light onto a sheet of matte plexiglass, then as a result you will get a semblance of a light screen. It is for this characteristic that plexiglass is appreciated by many consumers.

Production technology

To date, experts identify several ways of flat glass matting. At the same time, such a material can be made both in an industrial environment and independently.

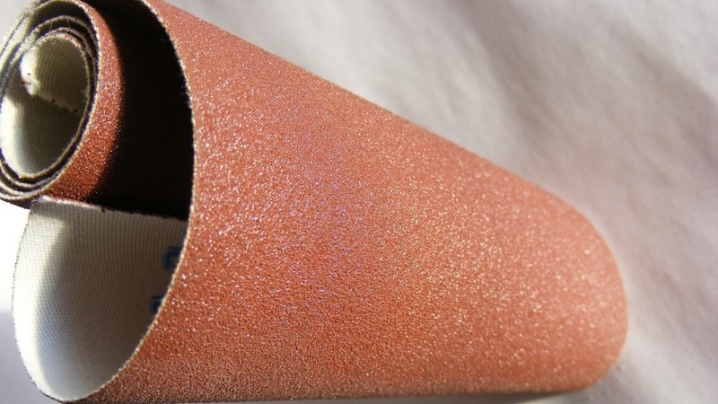

Mechanical matting

To carry out the matting procedure for organic glass, you will need sandpaper (this is where the name of the method comes from). In this case, it is recommended to give preference to this type of paper, which is characterized by a fine-grained appearance. So, sandpaper it is necessary to walk over the entire surface of the glass (while it is imperative to maintain the same level of pressure and pressure). For safety, it is recommended to use specially designed protective gloves.

Depending on your wishes, preferences and needs, you can mat the glass with sandpaper on one or both sides.

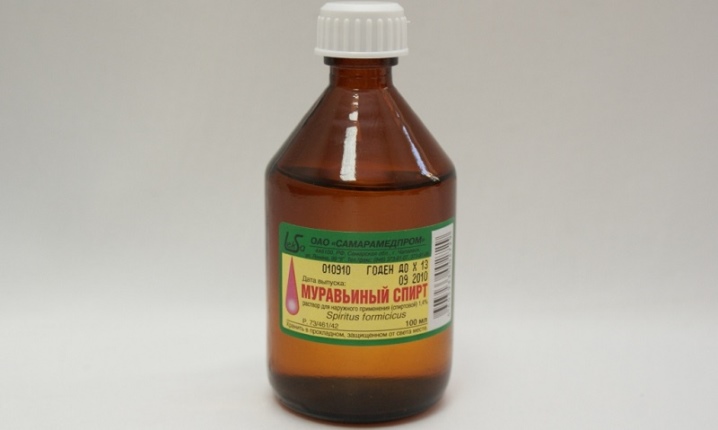

Chemical method

This method of matting does not require physical effort, but it is considered more dangerous than mechanical. Chemically matting is allowed only small-sized plates. This is due to the fact that for safety, as well as for the best effect during the matting process, you will have to place the material in a specially designed cuvette. In this case, the cuvette itself must have acid-resistant characteristics. The matting procedure itself should not be carried out indoors, but outdoors.

So, the glass should be put into a prepared cuvette and then filled with formic acid. In such a solution, the material must be kept for at least 30 minutes. At the same time, to achieve the best effect, it is recommended to periodically stir the acid with a metal stick.After the time has elapsed, the plexiglass must be removed and rinsed under warm running water. Important. During the implementation of chemical frosting of glass, you must be extremely careful and attentive. It is imperative to use protective equipment, and in no case should you bend low over the cuvette with acid, so as not to inhale the harmful vapors of the chemical.

Painting

This matting method is the fastest and easiest - it does not require a lot of financial and time expenditures. So, in order to matte the glass, it must be covered with a thin layer of white paint. At the same time, depending on your needs and requirements, you can paint the glass in one or several layers.

Thus, There are various methods and technologies for making matte plexiglass. Depending on your capabilities and abilities, you can choose any of them and create the material you need yourself at home.

Views

Due to the fact that frosted organic glass is a popular and demanded material, you can find several varieties of such a product on the market. Each of the existing types has its own unique characteristics and traits, therefore it is used for different purposes.

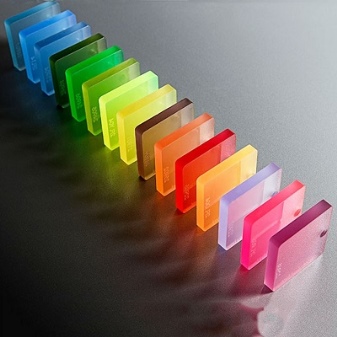

- Colored... The color of frosted organic glass is given by a special component that is part of the material. At the same time, on the market today you can find black, milk, white, red, green glass (as well as many other colors). The surface of the material itself can be smooth or rough.

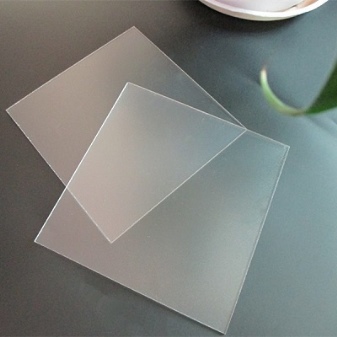

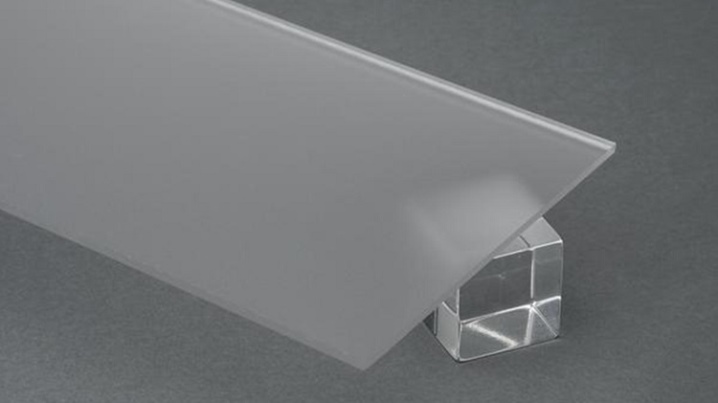

- Satin... This type bears its name due to the similarity with the popular fabric - satin. In this case, the material can be colored or transparent. One or both sides of the glass can be rough.

- Glossy... Already by the name of this type of organic material, one can guess that both sides of it are smooth to the touch. The color of the glass is milky. However, the saturation of this hue can fluctuate within certain limits. If you decide to purchase such a material, you should keep in mind that any defects and damage will be clearly visible on its surface.

- Corrugated... It can be white or colored. At the same time, a distinctive feature of this type of material is the presence of a pattern on its surface, which is quite clearly visible on the surface.

- Plexiglas... This type of frosted glass is also often referred to as acrylic. The material is widely used in a wide variety of areas of life.

When purchasing a material such as frosted plexiglass, you should also remember that the material can vary in thickness. You can find the corresponding markings on the packaging (for example, 2 mm, 3 mm, etc.).

Advantages and disadvantages

Like any other material, matte plexiglass has its own unique characteristics and features. Moreover, not all of them are positive, there are also negative properties. The advantages of the material include the following properties:

- affordable price;

- ease of maintenance and operation;

- high rates of plasticity;

- small weight;

- safety in use (glass does not break, but only cracks);

- strength and reliability;

- long service life, etc.

As for the negative characteristics, it is worth remembering that organic glass is a rather fragile material that does not withstand large mechanical loads and requires careful handling.

Application methods

Frosted plexiglass is a popular material that is widely used in a wide variety of areas of human activity:

- advertising (glass sheets are used to make a variety of signage and lightboxes);

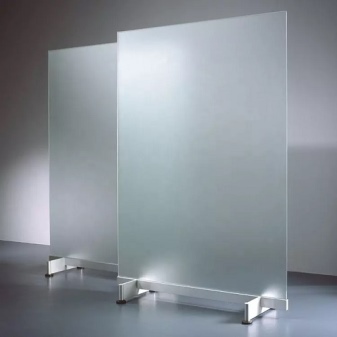

- Interior Design (a variety of interior details and elements can be made from the material: for example, partitions for pipes, vases, shelves, etc.);

- lighting (shades for chandeliers and sconces are often made of plexiglass), etc.

For information on how to polish plexiglass, see the next video.

The comment was sent successfully.