Fiberglass characteristics and applications

Fiberglass is a fairly common material based on quartz sand. It is widely used for the production of building materials and high-tech structures. Let us dwell in more detail on the features of the material, its advantages and disadvantages, as well as the scope of application.

What is it and what is it made of?

Glass fiber is a fiber formed from glass. In this form, glass exhibits unusual characteristics - it does not crack or break, but it easily takes on a curved shape.

Fiberglass threads of natural origin can be found in regions where volcanic eruptions once took place.

They are called Pele hairs, their chemical composition is close to that of basalt rocks. However, in terms of their physical and technical characteristics, they cannot be considered complete analogues of glass threads.

Fiberglass was first made by accident - an accident occurred in the glass industry, under the air pressure the molten mass swelled and divided into thin flexible threads. This came as a huge surprise to the engineers, since the glass usually hardens after solidification. More than 150 years have passed since that moment. During this time, the technology has been improved many times, but its principle has remained unchanged.

For the manufacture of fiberglass, quartz sand is used; during recycling, cullet is used - it can be glass containers, broken glass or rejected glass products obtained in production conditions. Waste from glass production is 100% recyclable. This leads to the use of recyclable materials in production - it can significantly reduce the cost of the finished material and maintain environmental protection of the environment.

The technology boils down to blowing the finest threads from raw materials. For this, raw materials are melted at a temperature of 1400 degrees. The viscous mass enters the molding unit and is passed through a centrifuge. The result is glass wool with intermixed fibers. At the finishing stage, the resulting semi-finished product is passed through a micro-perforated sieve and blown out under high air pressure. At the exit, even long threads are obtained, which later serve as raw materials for creating more complex products.

The resulting fibers can be of two types.

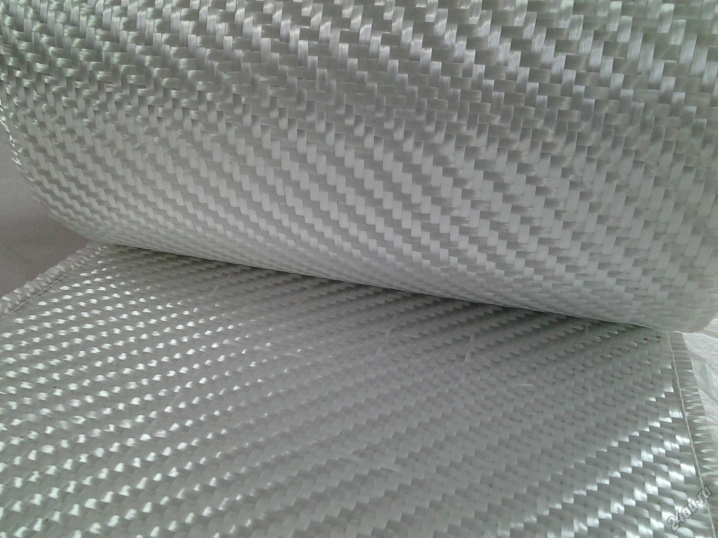

- Long strands - stretched over thousands of kilometers, they are obtained by a continuous method. Thin streams flow out through the holes, are cooled and wound on the drum. Outwardly, such a fiber resembles a silk thread. In the process of drawing, the threads pass through a sizing unit, are impregnated with adhesives and plasticizers. This processing produces flexible fibers.

- Short threads - have a length of 35-50 cm, they look like felting wool. The production is based on the staple technique - the molten glass mass is blown out with steam or hot air.

Depending on the thickness of the threads, there are:

- thick fiber - more than 25 microns;

- thickened - 12-25 microns;

- thin - 4-12 microns;

- superfine - 1-3 microns.

The production of fiberglass is subject to the current GOSTs:

- for fabrics for construction purposes - GOST 19170-2001;

- for insulating material - GOST 19907-83.

Main characteristics

Fiberglass has a number of advantages that determine its widespread demand in various sectors of construction and industry.

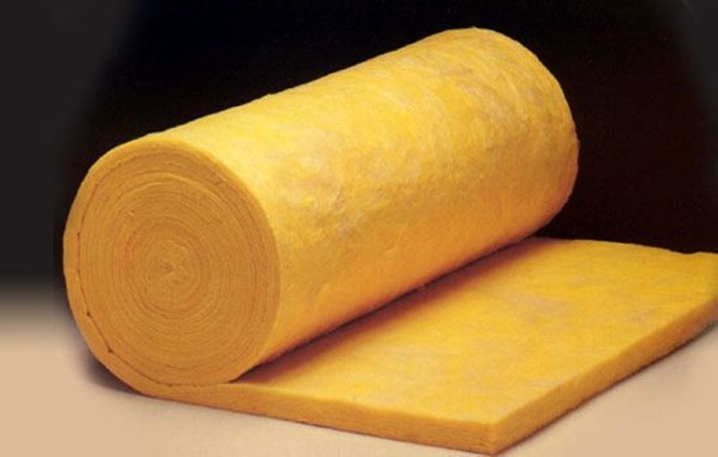

- The material has a low thermal conductivity, so glass wool is used for thermal insulation. Glass wool has the lowest indicator - its thermal conductivity corresponds to 0.05 W / m * K. Thanks to this, the room is kept cool in summer, and in winter the heat does not leave the building.

- Fiberglass is acid and alkali resistant. It is characterized by increased chemical inertness, since it consists almost entirely of quartz sand. Under the action of aggressive solutions, a chemical reaction does not occur, therefore, fiberglass can be successfully combined with any building and finishing materials.

- The threads are high-strength, the density corresponds to 2500 kg / m3. At the same time, the threads are fluffed, so the finished product has a large volume in combination with a low weight.

- Fiberglass is often used to make fire fighting equipment. This is a heat-resistant material with a melting point of 1200 degrees - such heating can be provided only with the direct action of the burner. In theory, it is possible to create conditions in which a fire will occur. But in this case, flammable binders must be present in the fiberglass, which is extremely rare.

- The material has an unusual structure. In it, the space between the fibers is filled with microscopic air bubbles. This achieves a high soundproofing effect.

- Glass fiber has the ability to resist deformation and resist wear, so it retains its original shape for many years.

- The material is flexible, thin, but elastic. During transportation, it can be folded or rolled up in rolls - this will not affect the performance of the canvas. This allows you to save space in freight transport and, consequently, reduce transportation costs.

At the same time, fiberglass has its drawbacks. So, when wet, it loses its operational properties. However, when they dry, they are restored again. That is why the material can only be used in conjunction with reliable waterproofing.

Fiberglass does not respond well to abrasion and frequent bending. To remedy the situation, treatment with varnishes and resins will be required.

The numerical values of the listed physical and technical parameters directly depend on the fiber manufacturing technology, its thickness, chemical composition and the effect of certain external factors.

Varieties

Among the variety of fiberglass products presented, two groups of materials can be distinguished:

- 100% raw materials;

- composite - additional components are introduced into the composition, giving certain performance characteristics.

Depending on this, fiberglass is produced in several types.

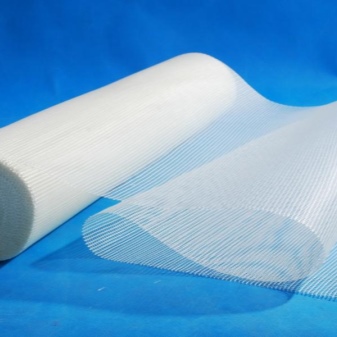

- Glass wool mats - such products are widely used in the industrial and construction sectors. It is in demand during installation for noise and heat insulation. The structure of the mats involves the connection of directional strands of threads, connected to each other in a natural way. These products are 100% fiberglass.

- Roll glass wool - in composition and method of production, this product is absolutely identical to mats, only it is produced in the form of rolls. This form is considered more practical for performing some types of thermal insulation work.

- Fiberglass mesh - such a product is used to perform reinforcement of various types of surfaces when performing repair and finishing works. The structure is made up of glass threads woven with each other and treated with special impregnations. It can be produced in sheets and rolls.

- Self-adhesive tape is produced on the basis of fiberglass mesh, for its manufacture, an acrylic or siliconized binder is applied to a glass base. The finished product is characterized by high strength at low thickness, good maintainability and undemanding dismantling. This tape is used for gluing joints and gaps between sheet panels.

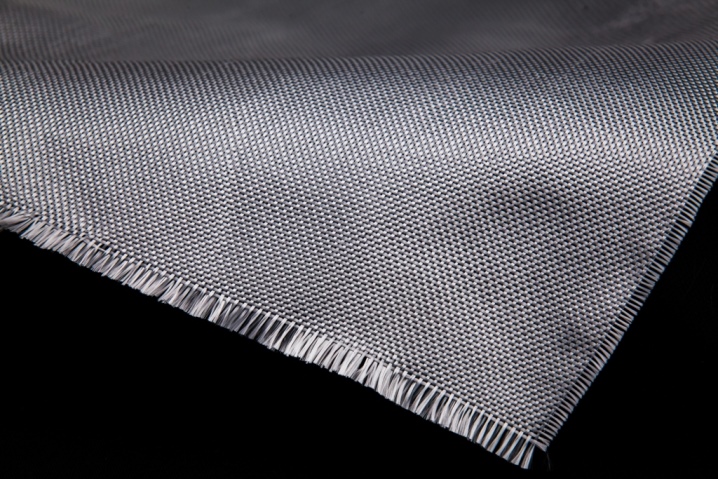

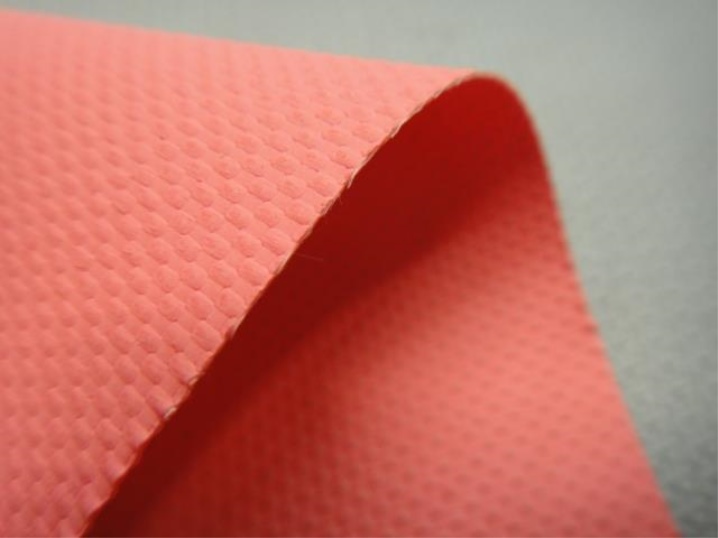

- Fiberglass - in terms of functionality, it is similar to the mesh, but differs in a denser interweaving of glass threads. It is carried out using weaving technology. Used in manufacturing and electrical engineering.

- Fiberglass - a universal composite. Consists of glass threads with the addition of polymer resins. It is molded, therefore it allows the production of a wide variety of parts.

- Fiberglass reinforcement - a good alternative to steel counterparts, can replace metal in most applications.

For the manufacture of products, fiberglass of several brands is used, made according to various technologies with different parameters of the thickness and length of the threads.

According to the type of coating, all types of fiberglass are divided into several categories.

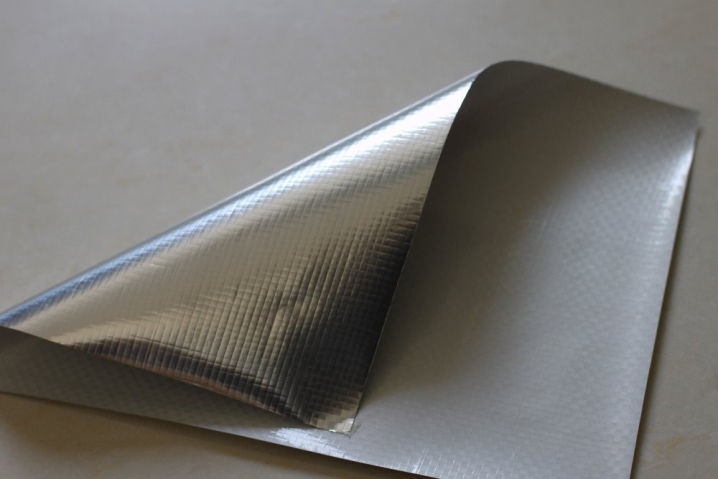

- Foil - the most common type of materials, in this case the glass cloth is covered with aluminum foil. The gluing of the fibers to the foil is performed by high-temperature exposure to the main components of the product. Such foil does not delaminate, does not allow water to pass through and protects glass filaments from UV rays.

- Silicone - impregnated with silicone on one or both sides. Moreover, the thicker the coating, the higher the water and gas trapping ability of the material. Such products are resistant to vibration waves and have a long service life.

- Polyurethane - impregnation multiplies the material's resistance to wear and aggressive substances. Such a canvas is used for the manufacture of products that have an anti-fire purpose.

- Fluoroelastomer - resistant glass wool, successfully resisting the action of fuels and lubricants and high temperatures. It has become widespread in the aviation and chemical fields.

- Graphite coated- such products must be reinforced with steel wire. Fiberglass is characterized by water and vapor permeability, and does not emit toxic compounds when heated.

- Hydrophobized - fabric with water-repellent impregnation and high dielectric properties. The main purpose of such fiberglass is protection against aggressive effects of water and current.

Manufacturers overview

One of the most famous fiberglass manufacturers in Russia is company "TechnoNicol"... It produces high quality building materials that meet all European standards. The enterprise uses all the advantages of glass cloth when creating heat-insulating and roofing structures, materials for insulation of main pipelines and many other products.

Is in great demand BauTex Ortex products... This is a high quality fiberglass made using German technology. The product of this brand is in demand in shipbuilding and aircraft construction, and is used in the manufacture of fiberglass plastics.

Glass cloth of the company "RATL" is a practical base for roof work.

Applications

Due to its exceptional technical and operational characteristics, fiberglass is in demand in a wide variety of areas.

Construction

In the construction industry, fiberglass is widely used as an insulating material for foundations, walls, ceilings and floors. It is used to improve the thermal protection of residential and industrial buildings, as well as pipelines. For this, glass sheets, mats, and glass wool rolls are used.

Fiberglass is often used for arranging soft roofs, as well as dense roofs. For this, glass yarns are combined with composite additives.The result is a beautiful material that is resistant to ultraviolet rays, heat and moisture.

To create construction objects, fiberglass is used - a composite based on fiberglass and polymer components. Protective architectural elements and thermal insulation panels are produced from it.

Fiberglass wallpaper is widely used in finishing works; a grid is used for plastering.

Refractory and non-combustible fiberglass is often used to insulate thermal furnaces, heating vaults, and lining chimneys and ceramic boilers.

Fiberglass is also used in road construction. The cloth, laid using fiberglass reinforcement, acquires high strength. It can withstand intense loads and does not crack with use. This material is more practical than concrete, and it also reduces the height of the asphalt layer. The use of fiberglass materials prevents potholes and thereby increases the comfort of road travel, increases the time between repairs and contributes to the durability of the coating.

Not a single construction of dams, storm sewers, bridges and embankments can do without fiberglass glass. Most of the septic tanks, bumpers and sedimentation tanks are also made of fiberglass.

Despite its widespread use in the construction industry, in recent years, fiberglass is inferior to the position of basalt wool. The latter significantly wins in terms of thermal insulation, its fibers do not crumble and do not irritate the skin, mucous membranes of the eyes and respiratory organs. This is why fiberglass is mainly used today for insulating pipes.

As for fiberglass, they are made of a long thread, so they do not crumble. Their use is completely safe for people and pets. In addition, they look impressive and can become a real highlight of the interior.

Medicine

With a stable structure and the exclusion of crumbling parts, fiberglass is completely safe for people. Therefore, it is often used to create prostheses and implants, including dental ones. The material is in demand in the production of some types of surgical equipment.

The use in this area confirms the safety of the material for health. Only the smallest particles of fibers and glass dust that surrounds glass wool, and also forms when sawing fiberglass, can cause damage. In all other ways of using, the material is harmless.

Production of goods

Fiberglass is in demand in the creation of watercraft, aircraft construction and other industries, where ease of maintenance, corrosion resistance and affordable cost are key factors.

Fiberglass is used to make instrument cases, cover boats and boats, and machine elements.

Depending on the parameters of fiberglass threads, other products are also produced:

- sanitary devices - showers, septic tanks, as well as bowls for pools;

- sports items - ski poles, rowing oars, spinning rods and fishing rods;

- packing containers - containers, trash boxes;

- all kinds of pipes for household use - holders, antennas, flagpoles.

This is not the whole list of areas where fiberglass is used. Every year, the scope of application of the material is expanding more and more, capturing new areas of activity.

Electrical insulation of conductors

In everyday life, glass threads are used to insulate wires in lamps, since this material is a dielectric. Glass fiber fabric is made from glass filaments and wrapped around the conductor.

In the industry, glass yarns are used in the following situations:

- wire winding;

- insulation of the transformer winding;

- production of electronic boards;

- production of foil-clad dielectrics.

Fiber is in great demand - long fiberglass filaments covered with a PVC sheath.

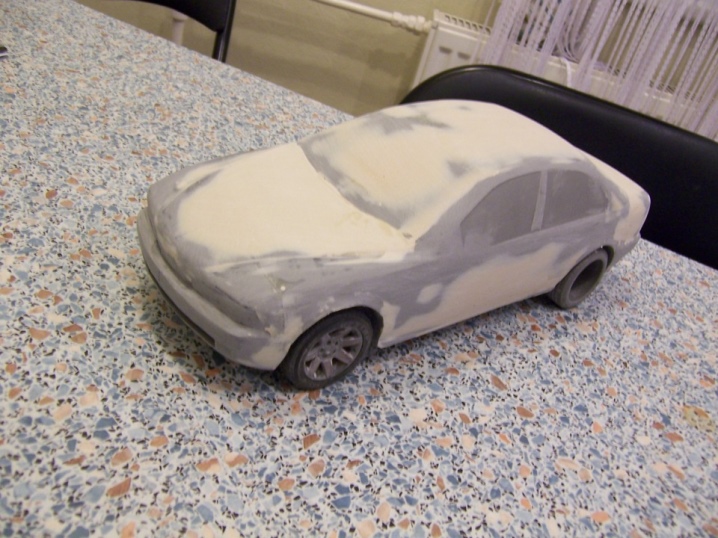

If desired, some fiberglass items can be made by hand at home. It can be anything from a heat-resistant kettle stand to a model car or even a homemade boat - nothing limits your imagination.

The easiest way is to use the technology of layer-by-layer application of fiberglass on the finished model of the product, each layer is glued with epoxy resin. This method can be used to make a car bumper, dashboard, or even a watercraft.

The most important thing is to correctly make the model on which you plan to glue the layers of fiberglass. The model can be made from wood, clay, plasticine and any other easily processed materials.

For ease of removing the frozen product, the model is treated with wax or paraffin.

After complete hardening, the workpiece is removed, cut along the required contour and grinding is performed. If necessary, holes are cut in the finished product.

The widespread use of fiberglass and products made from it has become available thanks to the achievements of modern industry in the production of composites and polymer materials. This is a universal product that meets all the realities of the time. It has the performance characteristics of the highest quality materials.

What are fiberglass fabrics used for, see the next video.

The comment was sent successfully.