Plexiglass milling technology

Organic glass is one of the most demanded and frequently used materials. Partitions, doors, light domes, greenhouses, souvenirs and many other structures and products are made from it.

But in order to make at least something out of plexiglass, it must be processed on special equipment. In this article, we will talk about the technology of material milling and the machines with which this process is carried out.

Peculiarities

Plexiglas is a vinyl material. Get it in the synthesis of methyl methacrylate. Outwardly, it is a transparent plastic material, which is considered completely safe for human health and has excellent physical and technical characteristics. It is very easy to process.

Plexiglass milling is one of the main methods of material processing. It is used when organic glass:

- outdoor or interior advertising, packaging, advertising structures are produced;

- the interior, racks, showcases are made out;

- decorations are created.

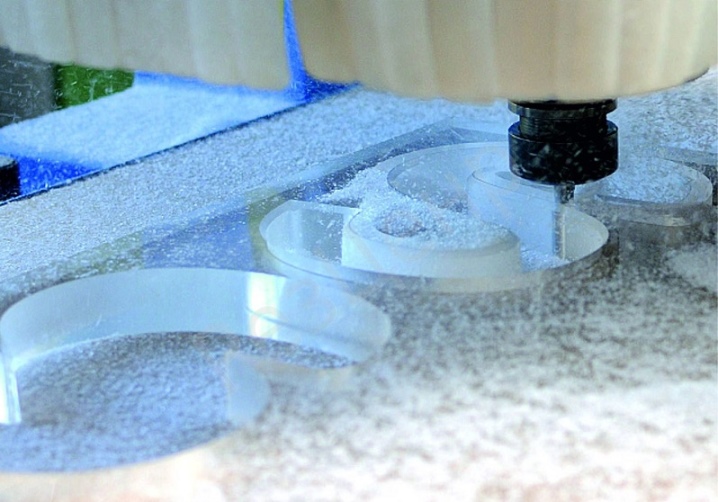

Also, milling makes it possible to make even the smallest details from plexiglass, for example, decorative elements, souvenirs.

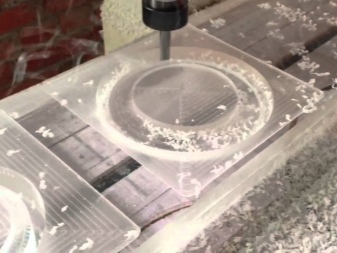

The biggest advantage of such processing is the ability to perfectly and effectively remove chips from the material, thereby achieving a perfectly flat surface of the product. This method is characterized by high cutting speed and clean cuts.

Milling solves many seemingly impossible tasks:

- cutting;

- creation of volumetric parts from material;

- engraving on glass - you can create recesses, form a pattern, an inscription;

- adding light effects - cutters are installed at a certain angle, thus creating light bends

Methods

Milling cutting of organic glass should be performed only by professionals using special equipment, milling machines. A milling machine is a special professional device with which you can cut and engrave plexiglass.

Currently, there are several types of milling machines.

CNC milling machine

This model is the most popular and demanded. This is primarily due to the peculiarity of the equipment - the ability to create in advance, using the program, taking into account the key parameters, a model of the product. After that, the machine will automatically do all the work.

The CNC machine is characterized by the following parameters:

- positioning accuracy;

- the size of the working surface;

- spindle power;

- cutting speed;

- the speed of free movement.

The parameters of each machine may differ, they depend on the model, manufacturer and year of manufacture.

There are several types of CNC milling machine:

- vertical;

- cantilevered;

- longitudinal;

- broadly versatile.

Milling machine for 3D cutting

This model of the machine differs from others in the ability to perform 3D cutting of material. The cutting element is positioned by software in three different dimensions, axes. This cutting feature makes it possible to achieve a 3D effect. On an already finished product, it looks very impressive and unusual.

All milling machines are classified by purpose:

- mini milling - used in everyday life or in the learning process;

- tabletop - such machines are most often used in small production with limited space;

- vertical - This is a large industrial equipment that is installed in workshops, characterized by high cutting speed and long time of continuous operation, high productivity.

By the type of movement of the working surface, machines are of certain types.

- Vertical milling. It is characterized by horizontal movement of the desktop. Carries out rip and cross cuts.

- Console-milling. The cutting element remains stationary, but the working surface moves in different directions.

- Longitudinal milling. The movement of the working table is longitudinal, the cutting tool is transverse.

- Widely versatile. This model of the machine is considered the most popular, since the movement of the working surface and cutting are performed in different directions, which are predefined in the software.

How to do it?

Working with organic glass on milling equipment is quite complicated and requires certain skills, abilities and knowledge.

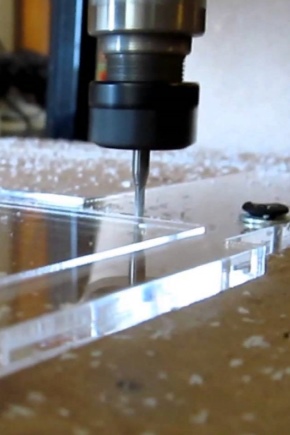

The milling technology is as follows:

- creation of a model of a future product;

- using a cutter, a sheet of organic glass is cut into parts of various shapes;

- the cut workpiece is placed on the working surface of the machine, fixed;

- the program is started, and the machine according to the previously created model starts automatic operation.

If the work is performed on a 3D machine, the program must set such a parameter, in addition to the thickness and depth of cut, as the angle of inclination.

After the plexiglass is milled on the machine, it is bent. For this, console machines are used. The already milled sheet is fixed on the console of the working surface, the program is set. The cantilever machine bends material according to the specified parameters and creates a specific shape.

It is not uncommon for people to manually try to mill. But without a special machine, this is impossible. Plexiglas is a rather capricious material, and cracks and chips may appear on its surface in inept and inexperienced hands.

Even if you decide to start milling the material yourself, be sure to follow the instructions for working with the equipment, adhere to technological norms and rules, and do not forget about safety precautions.

The process of fracking plexiglass in the video below.

The comment was sent successfully.