How to bend plexiglass?

Plexiglas is a transparent polymeric material with a dense structure, which can be given a certain shape or bent at the desired angle. The scope of application of plexiglass is quite extensive - decorative items, aquariums, stands, souvenirs, protective screens, designer accessories and much more are made from this material. Plexiglass has a high degree of transparency, so it can replace ordinary glass in interior doors, windows or decorative partitions. Acrylic polymer has good plasticity when exposed to certain temperature conditions. You can set the required configuration to acrylic not only by industrial methods, but also with your own hands at home.

Features of bending

Plexiglas acrylic glass is unlike ordinary glass in that it has the flexibility to bend this polymer plastic.

Curved glass retains its properties and does not change its configuration.

To work with acrylic, it is necessary to take into account a number of features so as not to spoil the material in the process of bending the glass:

- all manipulations associated with heating an acrylic blank, it is necessary to perform only on the back of the fold;

- temperature heating mode for acrylic cannot exceed 150 ° C;

- molded acrylic glass is melted at a melting point of 170 ° C;

- acrylic glass thicker than 5 mm, before bending, you will need to warm up on both sides.

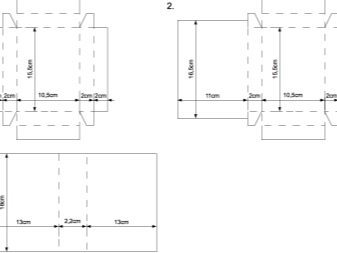

When performing calculations of the parameters of an acrylic product, it is important to take into account the material costs that will be used to create the bending radius. In order not to be mistaken in the calculations, it is advisable to make a template for the future product from thick paper.

After heating and folding the acrylic, it is necessary for the material to cool naturally at room temperature. It is not recommended to use cold water for cooling, as this can lead to the appearance of multiple cracks in the finished organic polymer product.

Any process of processing acrylic glass implies its warming up in the area of bending... Sometimes the workpiece is completely heated, for example, in the case of extrusion of volumetric figures from acrylic.

Preparation

Since acrylic is a synthetic material, it accumulates an electrostatic charge on its surface, thereby attracting dust and small particles to itself. Surface contamination reduces the transparency of the glass. Before starting the bending procedure, the acrylic sheet will need to be washed with a soapy water solution, after which the material should be dried for at least 24 hours.

To carry out a high-quality fold, it is important to perform correct heating of the material... It is necessary to heat plexiglass from the side opposite to the bend, that is, where the surface tension of the material will be greatest.

The heating surface area should be related to its thickness, in proportion it looks like 3: 1.

In order to prevent melting of the polymer surface of organic glass during heating, it is important to choose the right temperature regime. In the event of an error, the glass can not only melt, but also catch fire. The temperature range used for heating should be between 100 and 150 ° C.

How is it bent with a machine?

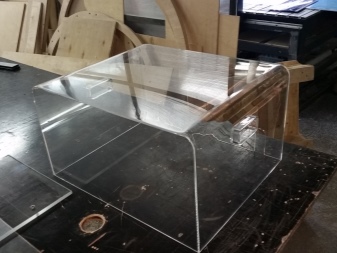

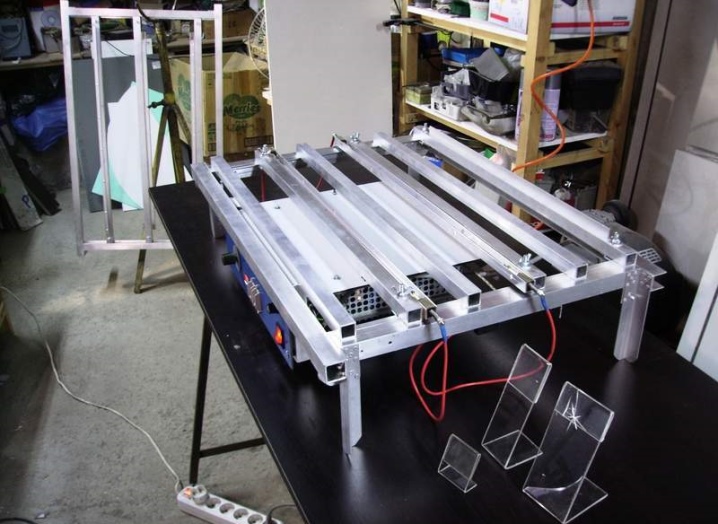

In the conditions of mass production, special equipment is used to bend acrylic sheet, which is called thermal bending machine. Using this device, you can perform high-quality heating of the sheet, and then its rectilinear bending. After the procedure is completed, the product is cooled. The bending machine performs all manipulations sequentially and automatically.

The principle of operation of bending equipment for acrylic is based on the use of nichrome thread, enclosed in a heat-resistant glass flask. The bending machine has the ability to bend polymeric materials, plastic and acrylic glass with a thickness of 0.3 mm to 20 cm. Equipment for bending polymers can be produced in the form of various modifications that allow processing workpieces with a width of 60 cm to 2.5 m.

Bending of acrylic glass is carried out evenly along its entire length. Equipment of this type is equipped with an electromechanical or pneumatic drive.

The bending machine has several built-in heating elements that can be adjusted according to the degree of heating and moved relative to each other at any selected distance within the machine circuit. In order to prevent overheating of the structure of the equipment body during operation, water is supplied in special cavities of the device for circular cooling.

The bending equipment has a number of advantages:

- the device can bend polymeric sheet material not only at a predetermined angle from 1 to 180 ° C, but also perform curvilinear bending;

- automatic machine does not need constant readjustment in the process of performing work;

- the equipment has the ability to heat thick workpieces from both sides at once;

- machine control can be performed in manual or automatic autonomous mode;

- the equipment can handle all types of plastic sheets.

By folding an organic sheet on a thermoforming equipment, you can be sure that the material will not be damaged. The fold of the products is performed with clearly defined parameters, without delamination inside the material, without the formation of cracks and bubbles.

Automatic devices have high productivity, they can be used to produce a large number of serial products, while spending a minimum amount of time.

Other methods

At home, a plexiglass sheet can be shaped with your own hands. There are various ways of performing bending work, thanks to which you can bend a sheet on a nichrome string along a radius of 90 degrees, or squeeze a hemisphere out of thin acrylic. You can process organic glass using various tools.

With a hairdryer

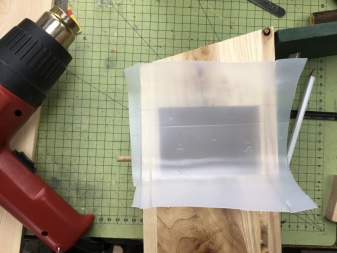

This method of processing acrylic is applicable in cases where it is necessary to bend a very large piece of organic glass. To warm up the working field with high quality, you will need a rather powerful tool, which is a building hair dryer. This high-power device blows out a stream of air heated to the required temperature. The flexion process is carried out in several stages:

- a sheet of organic glass is firmly fixed on the desktop with the help of carpentry clamps;

- take measurements and outline a line for performing bending of the material;

- the fold area is treated with hot air supplied from a building hair dryer;

- the material is treated with hot air until softening;

- the softened sheet is bent at the required angle;

- the finished product is cooled at room temperature.

If the treatment with a hairdryer is performed on organic glass of a small thickness, then the areas that do not need to be heated will need to be covered with a material that is resistant to high temperatures.

In hot water

Bending a small-sized plexiglass at home can be done using a fairly simple method, which is considered the least energy-consuming and quickest - you will need water to complete it. The process includes a number of steps:

- choose a container so that the workpiece to be processed can enter it, and water is poured;

- bring it to a boil;

- into boiling liquid for 5 minutes. lower the workpiece made of acrylic - the exposure time also depends on the thickness of the plexiglass;

- the workpiece is heated under the influence of hot water, then it is removed from the container;

- the workpiece is bent to the desired configuration.

The disadvantage of this method is that it is necessary to bend acrylic on a hot workpiece, therefore, it is necessary to provide for the presence of cotton gloves so as not to burn your hands while working.

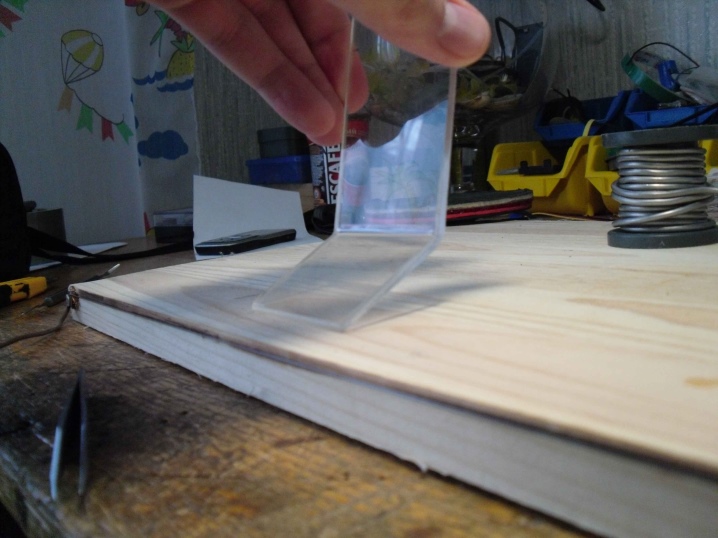

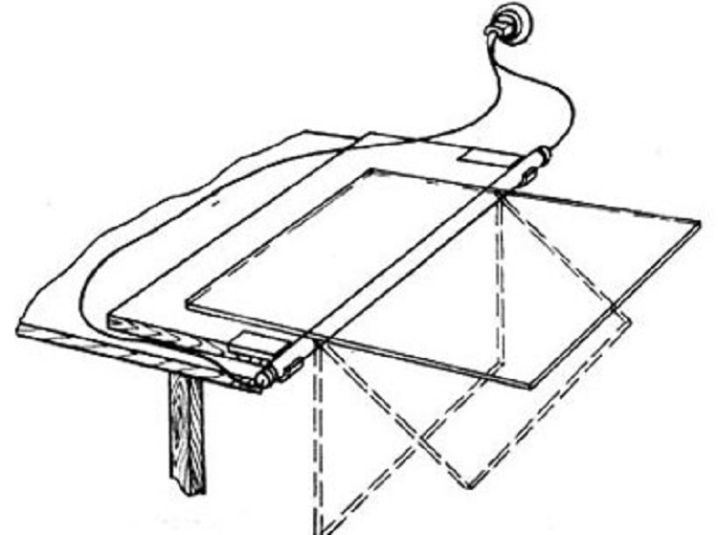

Special nichrome wire

You can perform high-quality bending of plexiglass using a nichrome thread. The procedure looks like this:

- a plexiglass sheet is fixed on the desktop with clamps, allowing the free edge at the bend to hang freely;

- a nichrome wire is pulled over the table at a distance of no more than 5 mm from the surface of the sheet;

- the wire is connected to a 24 V transformer;

- the transformer heats up the nichrome filament, and after it is very hot, the glass will slowly bend under the influence of heat and its own weight.

When heating nichrome wire, it is necessary to ensure that it does not sag and does not touch the workpiece.

When bending glass, do not speed up the procedure by helping it with your hands - this can lead to cracks or deformation of the material.

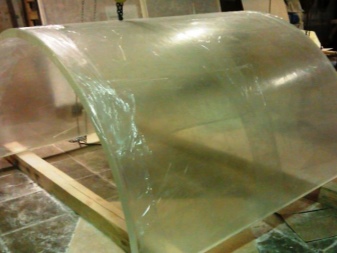

Metal pipe

To give the acrylic workpiece a certain radius of curvature, the method of bending plexiglass on a metal pipe is used. To perform this procedure at home, you can heat either the material itself or the pipe. A blowtorch is used to warm up the pipe.

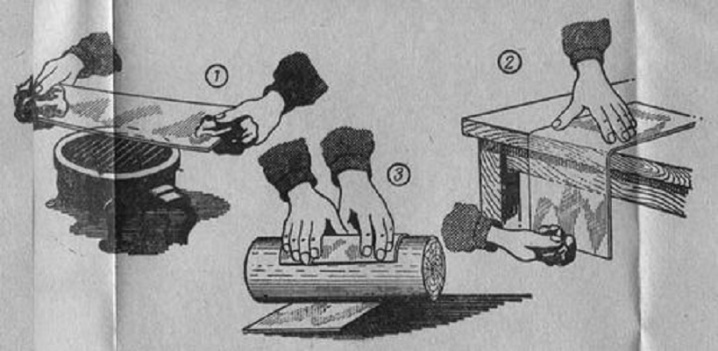

The flexion procedure is performed in the following sequence:

- a sheet of cold acrylic is applied to a pipe, the diameter of which is equal to the bending radius;

- with a blowtorch or a construction hairdryer, they warm up the folded area of the sheet;

- when the organic glass is warmed up and acquires plasticity, turn the sheet over the surface of the pipe with your hands;

- the procedure is repeated until the acrylic sheet is sufficiently folded.

If it is necessary to use the second method, then the pipe is first heated, and when it reaches the melting point of acrylic, the sheet is wrapped around the pipe, thereby making the necessary bend.

Hemisphere can be extruded from acrylic material... To do this, take a thin sheet of plexiglass (3-5 mm), a punch and a plywood matrix, in which a hole of the diameter you need is made. The diameter of the hole needs to be made a little larger, taking into account the allowance equal to the thickness of the organic glass.

In order to prevent the wood grain pattern from being printed on the acrylic blank, the punch and the surface of the plywood matrix are lubricated with casein glue, and then, when it dries, the film is sanded with sandpaper.

The organic glass sheet is heated before softening - this can be done with a gas burner, working with cotton gloves so as not to burn your hands. After the material is well heated, it must be placed on top of the matrix. Next, a hemispherical punch is installed on top of the acrylic. With this tool, the acrylic sheet is pressed, then held for 10 minutes. the entire structure until it hardens. Thus, the plexiglass acquires a semicircular configuration. A similar technology can be used to extrude any other shape, depending on the shape of the stencil and punch.

How to bend plexiglass, see below.

The comment was sent successfully.