What are the permanent formwork and how to install it?

The foundation is the foundation from which the construction of any house begins. To fill a concrete foundation of a certain shape, builders use formwork - frame auxiliary structures that play the role of a "mold" for building materials.

Previously, formwork made of wooden planks was considered to be running, but now, when building houses, a more innovative option is used - fixed formwork.

What it is?

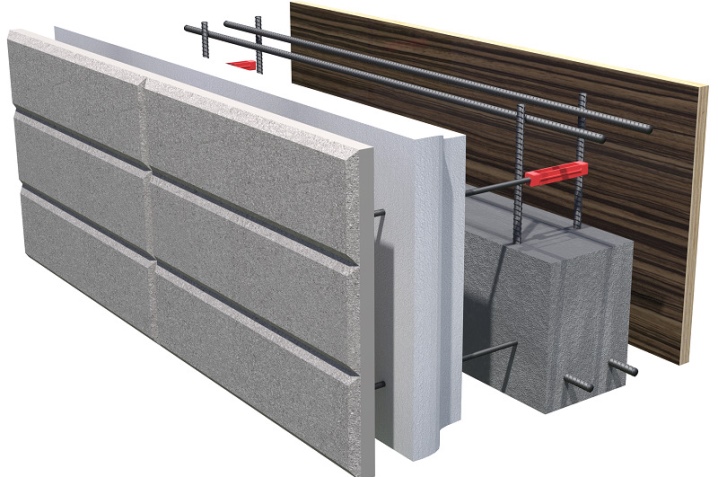

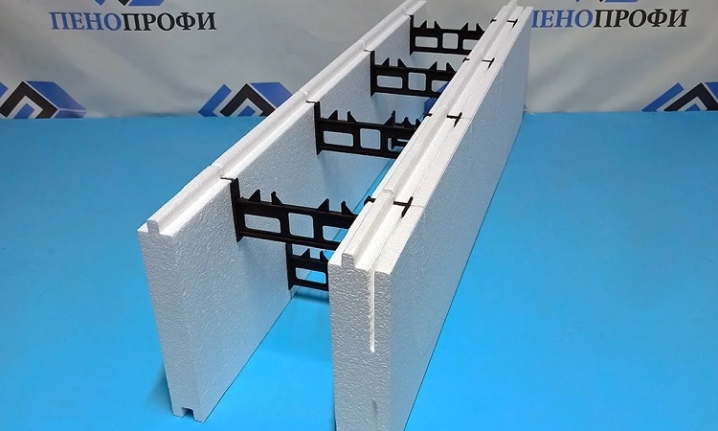

Permanent formwork is a block structure designed to be poured into concrete when creating a foundation, walls or floors. Outwardly, it looks like a row of solid cubes with a cavity for building materials. The main difference between this type of formwork and removable formwork is that after the installation of the structure and the subsequent pouring of concrete, the formwork becomes part of the structure.

While removable formworks are shields made of various materials and are subject to dismantling, fixed models, remaining in place after pouring, allow you to additionally insulate the house and strengthen the base. That is why such formwork is often used in the construction of private houses.

Together with the reinforcement frame, the formwork forms powerful reinforced concrete slabs used in construction. The quality of the entire slab directly depends on the correctly assembled formwork.

A quality fixed model should have the following characteristics.

- Strength... A low-strength structure is capable of cracking and bending under the weight of the poured concrete, thereby deforming the future foundation.

- Water resistance... The concrete mixture poured into the formwork is a thick, but wet mortar. If the structure allows moisture to pass through or has insufficient tightness of the seams, then the concrete will seep out, complicating the construction process.

- Uniform block shape... If the structural elements have uneven wall sizes or broken corners, then an even foundation simply will not fold.

- Long service life... Permanent formwork is the basis of the entire foundation, which directly determines how long the house will stand. Walls left without additional support can quickly collapse under the onslaught of the weight of the entire structure. If the selected formwork had a decorative finish, then the process of its corrosion can lead to the loss of the aesthetic appearance of the facade.

Advantages and disadvantages

A fixed structure has many advantages and allows you to build a reliable and monolithic foundation on the site. This technology significantly saves workers' time, since it does not require dismantling and is quite easy to use, as a result of which even a novice builder can handle the job.

The list of advantages of this design is quite extensive:

- fixed structure facilitates the construction process due to simple installation, reduced cost and light weight of the material, which can be transferred manually without resorting to additional installation equipment;

- the formwork provides a high level of sound insulation and thermal protection;

- the buildings being erected have high strength and reliability, therefore, the service life of the houses is tens of years;

- the form of expanded polystyrene does not allow moisture to pass through and has the ability to ventilate, thanks to which it is protected from the appearance of microorganisms;

- the design allows the construction of buildings of various scales, therefore it is actively used both in private construction and in industrial;

- most types of formwork are not picky about temperature conditions and type of soil;

- materials used for the production of permanent formwork are environmentally friendly;

- the facade of the building, made with the help of permanent formwork, is excellent for further construction using bricks, wood and other materials, which is very convenient for the construction of private cottages.

However, the installation of monolithic formwork is not the most ideal option if you are considering the construction of a multi-storey building. Despite the fact that the use of monolithic formwork in the construction of walls is possible, this technology is rarely used. The fixed type of construction is best suited for laying the foundations of one-story houses.

Also, builders may face the following disadvantages:

- expanded polystyrene formwork is not fireproof (the maximum temperature effect on the material is 90 ° C), therefore, it is recommended to additionally process the structure with non-combustible substances or materials;

- if there are metal elements (reinforcement) in the frame, it is necessary to provide additional grounding in case of a lightning strike;

- houses with permanent formwork require good ventilation systems, since the level of humidity inside is usually increased;

- if the structure requires dismantling, the process of disassembling the foundation (especially when using a reinforced frame) will be very difficult.

Views

In order to correctly choose the formwork, you need to pay attention to the material from which it is made. Formwork types differ in functionality and purpose. Reinforced concrete blocks stand apart, which give the facade special stability and strength, therefore they are often used for the construction of the most massive structures. The use of thin-walled concrete blocks is used in the construction of the foundation of fences. Some materials have the following features.

- For the construction of bridges, glass fiber reinforced concrete formwork is used... This technology is great for speeding up the process of erection of structures running over water bodies, highways or railways. Permanent formwork made of fiber-reinforced concrete helps to maintain the immobility of concrete in a given shape until it hardens completely.

- Magnesia glass material is used in the construction of thin walls and lintels. Outwardly, the result resembles an ordinary wall, but it has improved sound insulation compared to drywall.

- Metal formwork is considered to be durable, the walls of this material come out smooth, and formwork can also be used to create corners or arched structures. Despite these advantages, the material is very expensive, therefore it is rarely used in home construction. Often, metal formwork is used to create foundations on complex loose soils.

- Cement particle boards are composed of cement, sawdust and wood shavings, which add extra strength to the formwork and create breathable walls. Often used in private construction for the construction of residential buildings or fences. The only drawback of structures made of CBPB is low moisture resistance, and therefore, during installation, the plates must be provided with additional waterproofing.

- Extruded polystyrene - flexible material, which helps to erect structures with complex geometry and provide facades with additional thermal protection.

Among the many types of permanent formwork, the following options are most popular.

Facing

Formwork with a full external decorative finish... Fits for designer cladding of facades, however, it does not have thermal insulation, therefore, it requires additional wall insulation. To assemble the foundation, it is necessary to connect the finished blocks to each other, then pour concrete mortar inside and wait for it to harden.

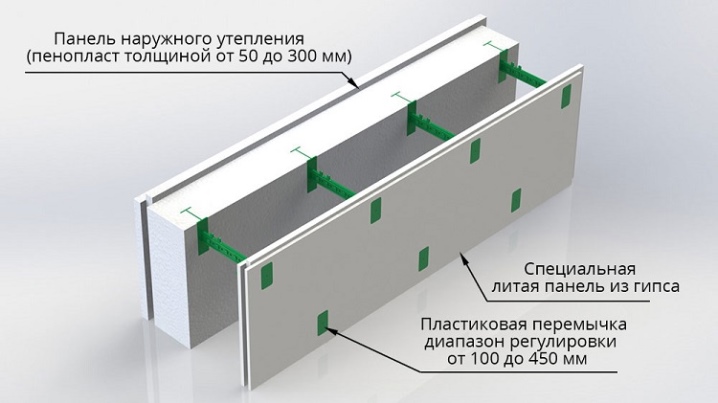

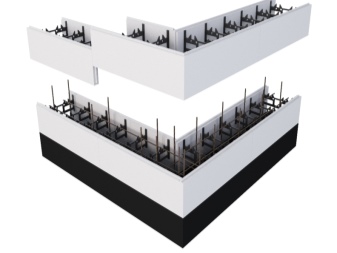

Armopanel

The use of armopanels allows installation using sandwich technology. The two panels are connected to each other, after which the concrete pour is poured inside. The resulting foundation has increased strength, however, it requires the installation of additional ventilation.

Arbolit

The formwork consists of wood chips, sawdust and cement, therefore it seems to be the most environmentally friendly material. Arbolite structures are easy to cut, heat-resistant (to both low and high temperatures), although to achieve complete thermal insulation, additional installation of expanded polystyrene between the blocks is assumed.

The main disadvantage is the massive thickness of the finished walls.

Glass magnesite

The formwork consists of magnesite glass sheets sheathed with a steel frame. Such material has good fire resistance and increased sound insulation, due to which it is often used in private housing construction for the construction of facades and even walls. The surface obtained from LSU comes out smooth and even, and also has environmental friendliness.

Styrofoam

For the foundations of large buildings, a foam structure is often used. In some cases, with the help of such formwork, walls can be laid, but this is an expensive undertaking.

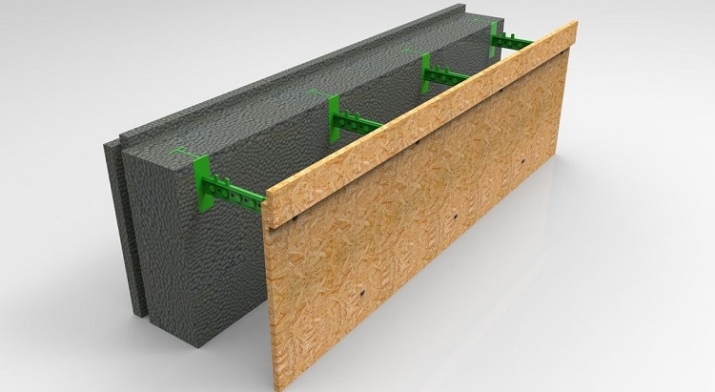

Plastbau 3

Represents panels made of expanded polystyrene using a metal frame made of reinforcement... Due to its appearance, the formwork has a number of advantages: quick and easy assembly process, high strength and additional thermal insulation. One Plastbau 3 panel is approximately the size of a residential floor. Thus, formwork can be used for monolithic construction of multi-storey buildings.

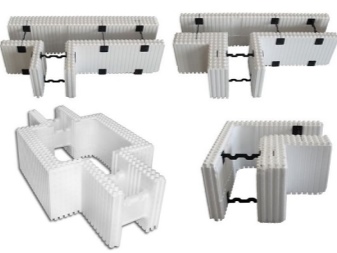

Expanded polystyrene

Expanded polystyrene is one of the most popular materials. Builders appreciate the expanded polystyrene structure for sound and thermal insulation, low weight and ease of installation (the use of foam blocks greatly facilitates the work due to the convenient large dimensions, but low weight). Among the main disadvantages of the material are the low combustion temperature and poor environmental friendliness, which can be fraught with health and the environment.

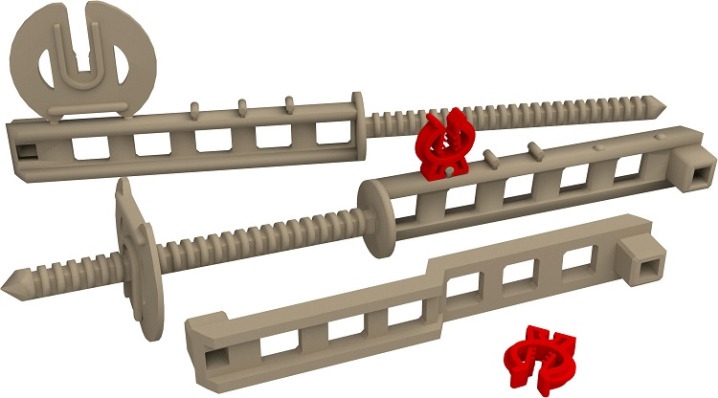

Overview of connecting elements

To fasten the blocks of the permanent formwork together, it is not necessary to use expensive fasteners. Such inexpensive elements as self-tapping screws, metal corners, nails may be enough. Even glue is used (suitable for wood concrete formwork). However, some types of permanent formwork (for example, extruded polystyrene foam) are capricious about any standard types of fasteners. For the most reliable fastening, the following elements are used: struts, ties, brackets, clamps, spacer bars, as well as fasteners made of durable plastic that can withstand high pressure.

Let's consider the most common components.

- Braces... Needed to give the formwork wall the correct position.

- Leveling beams. They are used for additional reinforcement of the formwork structure.

- Screeds... Most often they are used in the construction of monolithic buildings to fasten the walls together.

- Various brackets, spacer bars. Needed to create a support in the formwork.

Applications

Structures with the use of fixed formwork are used both in industrial-scale construction and in the installation of private houses, cottages, and fences.Since the use of this technology greatly facilitates construction, reduces time and material costs, home owners often use various types of permanent formwork for foundation construction on personal plots.

The most common areas of application for fixed formwork are:

- construction of walls and foundations of cottages, private auxiliary structures (garages, fence posts, gates, outbuildings);

- construction of multi-storey monolithic buildings on an industrial scale (both residential multi-storey buildings and public buildings);

- laying floors on the ground in areas with low groundwater levels;

- superstructure of additional basement floors;

- auxiliary wall insulation.

Expanded polystyrene formwork is actively used for the construction of swimming pools, as it provides a good level of thermal insulation, thereby helping to avoid rapid cooling of water.

For large-scale works, metal structures are most often used as wall formwork (for complex architectural structures for transport purposes, it is preferable to take steel, and for residential buildings with a lower load, aluminum is suitable).

Installation technology

To build a house using permanent formwork yourself, you do not need any special skills or practical skills.... Most materials are lightweight and hand-carried, which makes the process much easier. If the budget allows, you can purchase a vibropress and manufacture concrete blocks for future formwork yourself. Before starting work, it is necessary to check the level of the base of the foundation. If there are irregularities, they are disposed of by leveling with cement mortar. If you need to make an insulated foundation, a warm floor is mounted on the finished frame from the reinforcement before pouring the solution.

The installation process can be divided into 3 main steps:

- assembly of blocks;

- layout of reinforcement;

- pouring concrete solution.

The most important point is the installation of the first block row. Before proceeding with the installation, it is necessary to lay a waterproofing layer on which the formwork will be erected. The first row sets the accuracy of the foundation. When laying out blocks, it is necessary to verify every centimeter and monitor compliance with the calculations.

The blocks are placed so that there is a small free space between them, which is necessary for laying the reinforcement. Metal rods play an important role in the installation of subsequent rows of formwork, being a connecting and fastening structure. If the formwork is not installed tightly, then the poured concrete will move the blocks, acquiring a shape that is far from the specified dimensions, and will also flow out of their limits. For the private construction of small houses, two rods are placed in the slot, but for larger buildings, three can be used.

The second layer of blocks is stacked on top of the first with a slight offset to the side, as a result of which the assembly of blocks becomes like a game of chess, where each subsequent row is shifted relative to the previous one. To start pouring the mortar, it is necessary to install at least 3 rows of blocks, otherwise there is a risk of hollow spaces surrounding the reinforcement, and, as a consequence, the formation of a fragile structure. The blocks are interconnected by means of tongue-and-groove plates.

After installing the required number of blocks and subsequent reinforcement, concrete is poured into the finished form. The solution level should not reach the metal rod slots.

It is necessary to wait until the poured layer dries up a little, and then continue laying the formwork.

Now, for the subsequent filling, it is enough to set 2 layers of blocks. When the required foundation height is reached, the last layer of the poured concrete mortar should form a flat surface reaching the edges of the formwork.Then the concrete must be leveled before it has time to harden.

The comment was sent successfully.