Inventory formwork: types and installation

Inventory formwork is one of the most important elements in construction work. Customers need to know what metal shields for monolithic construction and other options are. You will have to take into account the dimensions and rules for installing floors with your own hands, other subtleties.

What it is?

It should be pointed out right away that inventory formwork is a characteristic component of modern monolithic construction. When this type of construction was just beginning to develop, many difficulties had to be faced.

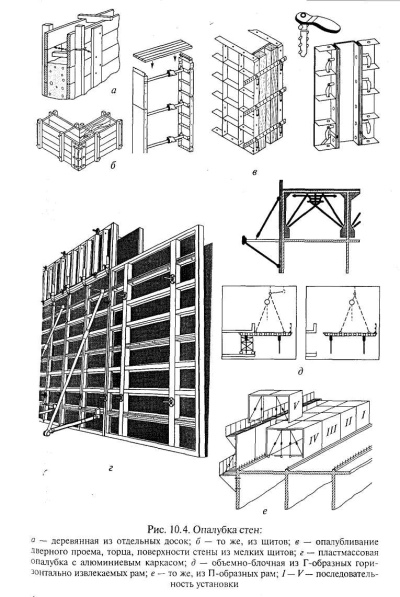

Traditional wooden shields, of course, helped to a certain extent. However, by definition, they could not be hermetically sealed. Wood was quite expensive, it was possible to prepare structures from it only by hand, and it was impossible to reuse such types of formwork.

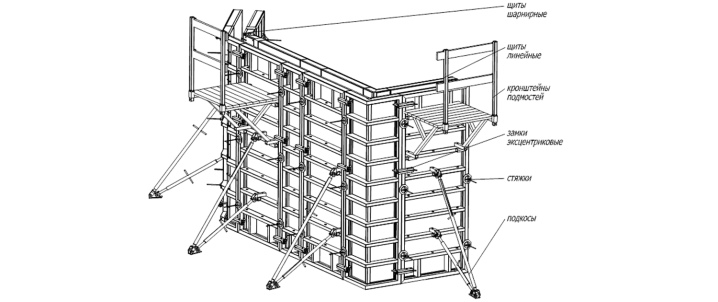

The correct inventory formwork can be applied many times without the slightest quality issue. Installation is very fast, which simplifies one of the most difficult jobs. Fixing the shields does not pose any particular problems. Such shields can be fastened (regardless of size) along any possible edge. Sometimes blocks and panels are assembled from them.

Application

Inventory formwork is needed for monolithic construction primarily because it allows you to cast good solid monoliths. The design can affect:

-

geometric parameters;

-

texture;

-

spatial arrangement of elements.

Formwork is used for:

-

erection of vertical structures of buildings and structures;

-

concreting of large-sized and massive structures;

-

concreting of various types of structures;

-

pouring foundations.

Types and sizes

The variety of tasks solved by inventory formwork determines its specialization. Large-panel and small-panel models are usually suitable for rearrangement. The mass of the structure is at least 50 kg. Also known:

-

climbing-adjustable modifications, which are needed to obtain elements of variable diameter;

-

volumetric-adjustable (they are needed when filling a wall or floor);

-

block versions of inventory formwork (needed for isolated fragments and for large-sized split blocks);

-

tunnel formwork with horizontal movement (used not only in the arrangement of tunnels, but also in the construction of water conduits, reservoirs);

-

pneumatic group of inventory formwork is one of the ultramodern types that can significantly simplify the construction of buildings with a curved configuration.

Size is, of course, just as important as type. The width of the shield varies from 0.25 to 2.4 m. Height is usually limited to 3.3 m. Higher structures are negotiated individually or even by special order. Linear parameters strongly depend on the material; so, the largest size are lightweight plastic structures.

Materials (edit)

Undoubtedly, metal panels are the classics of formwork. With all the achievements of modern construction, they will not be equal in prevalence for a long time. For the manufacture of a shield, steel up to 0.2 mm thick is most often used.

Thicker metal is used only as needed. Steel is relatively easy to bend, but it is very inexpensive.

Wooden inventory formwork is rarely used. Little of, many experts doubt whether it can be inventory at all in terms of its level. Plastic models are usually used if the height of a single structure is more than 4 m. Of course, everything is individual at each facility. And therefore it is necessary to consult with specialists before ordering.

DIY installation

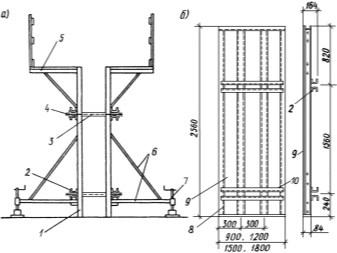

Inventory slab formwork - and other structures as well - is always carried out strictly according to calculation. The perimeter strapping is carried out using a drill and dowels. The accuracy of the geometry is controlled using a rule or level. The necessary lines are drawn with a cord. It is quite possible to put marks with a stationery marker.

It must be remembered that the table must be set up very carefully. Even exceeding the load for one rack alone can destroy the entire assembly. The installation step of the dowels is 50-80 cm. Important: the racks will not be a support, these are only indicators for the installation of walls and ceilings. Next, you need to pull these racks to the required length and secure using a lock or a special stop.

Rack elements are placed in such a way that they correspond to all the rooms being created. There should be 3 racks per 1 line of the girder. The beams should be inserted into the univilka according to the length of the crossbars. The support overlap is 30 cm.

The comment was sent successfully.