Choosing a lock for formwork

When using formwork in monolithic construction, close attention is paid to the connecting elements. They guarantee the stability and strength of the structure forming the concrete mixture, ensure its rigidity and impermeability of all joints. Let's talk in more detail about the types of locks (other names: clamp, "frog", riveter, "butterfly", reinforcing clip) for the formwork system, about their characteristics and ways of using each type. This will further make it possible to carry out the correct choice of lock connections for a specific design option.

Views

Today in the construction industry, the use of various locks for the formwork system is practiced. Each of them has its own performance and purpose. Therefore, before purchasing, it is imperative that you familiarize yourself with the device of the device. In the role of a mounting element for formwork, the following types of fasteners are used:

- wedge;

- spring;

- universal (elongated or "crocodile");

- screw;

- shock.

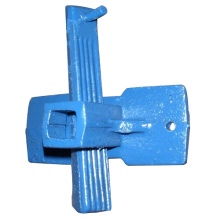

Wedge clamp

These are especially frequently used fasteners when constructing formwork panels, making it possible to precisely dock and align them, which, in turn, ensures a flawlessly flat surface to be concreted. Since this lock is non-separable, there is no need to fear the loss of elements during the installation process. The wedge lock is available in zinc-plated steel or cast iron and can work with both metal and aluminum formwork. The average weight of the castle is about 2.5 kilograms, but there are models that are several times heavier. Practical for timber or metal formwork systems. It is installed and fixed by means of a specialized key. Installation is carried out very quickly and without auxiliary tools, at the same time it is very convenient for the construction of fences of various designs.

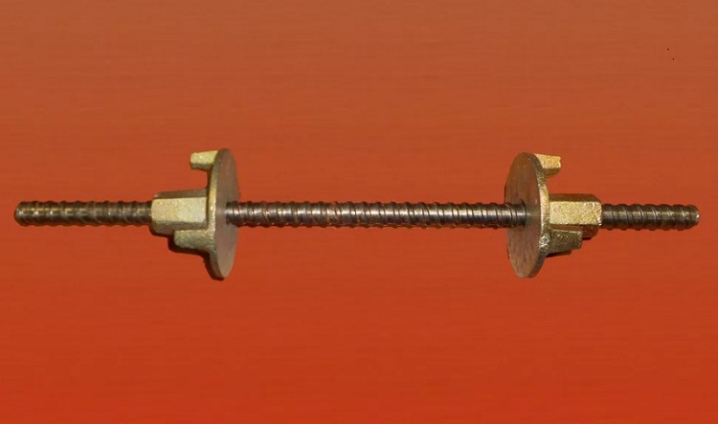

Spring clip ("frog")

This castle appeared in our country in the 90s together with builders from Turkey who brought advanced technologies of monolithic construction. Actually, for this reason, it is also called the Turkish clamp, and the models of the Turkish-made lock are still considered the highest quality today.

The spring clamp is designed for mounting on fittings with a diameter of 6 to 10 millimeters. Good because it can be used to install a formwork system made of any material. It has a high degree of operational reliability and is easy to install. Clamping pros:

- practicality in use;

- uncomplicated design;

- reasonable price.

The spring fastener can withstand loads of up to 2,000 kilograms, but there are also reinforced devices. This makes it possible to use it when assembling various types of formwork.

Elongated ("crocodile")

The use of an extended clamp for the formwork structure makes it possible to assemble and level panels from various materials. Another name for this fastener is the universal formwork clamp, since it makes it possible (if necessary) to use specialized inserts up to 250 millimeters wide. Also through it, you can connect shields at an angle of 90 degrees, which is especially important when building foundations. This clamp is suitable for all types of formwork structures.

Screw (clamp) clamp

Like other types of formwork fasteners, the turnbuckle is designed to mate the butt joints of panels and shields and align them. Clamps are made mainly of metal, and powder paint is used as a protective layer.

The disadvantage of this modification is considered to be a large mass. One device weighs approximately 5 kg, however, there are also heavier samples.

The peculiarity of the structure of the castle makes it possible to install extensions between shields up to 250 millimeters wide.

Impact lock

This type is used as a clamp for small-panel formwork structures. The lock has a special configuration specially designed for secure and solid connection of the formwork through the holes in the strap. The structure of the product makes it possible to integrate it into the system and then disassemble it simply and quickly (practically in a few seconds) using manual work. An ordinary hammer is used to mount the clamps, as a result a strong and tight connection is guaranteed. Installation does not take much time, the clamp is suitable for the overwhelming mass of types of formwork panels.

Appointment

All of the locks presented above give the joints rigidity and stability. Their main purpose is to maintain the required configurations of the structure, which is filled with concrete mixture.

Moreover, by means of locks, the panels of the formwork structure are firmly connected to each other, due to which they withstand the impressive technological loads formed by the concrete solution. Spreading, placing and compacting concrete mix becomes simpler, reducing labor time and even money.

Selection rules

You need to start from the place where you purchase the product. Do not trust suspicious companies that have been on the market for a few days. All accompanying documentation must be available, since safety at the construction site directly depends on the locks, therefore, they must fully comply with the current standard.

Usually, locks are made of 35GL steel, gray cast iron or an alloy of cast iron and steel. Coverage also matters. It can be galvanized, oxidized and powdery. Additionally, there are samples without spraying. Their cost is much lower, however, and the duration of use is much shorter. When placing an order, pay attention to the maximum maximum insert thickness.

When purchasing clamps for a formwork system, the following criteria should be taken into account:

- type of formwork structure: small or large panel, for columns, walls, foundations, and the like;

- the size of the budget for the construction of the formwork structure;

- requirements for the rigidity and strength of the formwork system.

The advice of the formwork manufacturer, who has considerable experience in the installation and use of various types of formwork systems, should be taken into account.

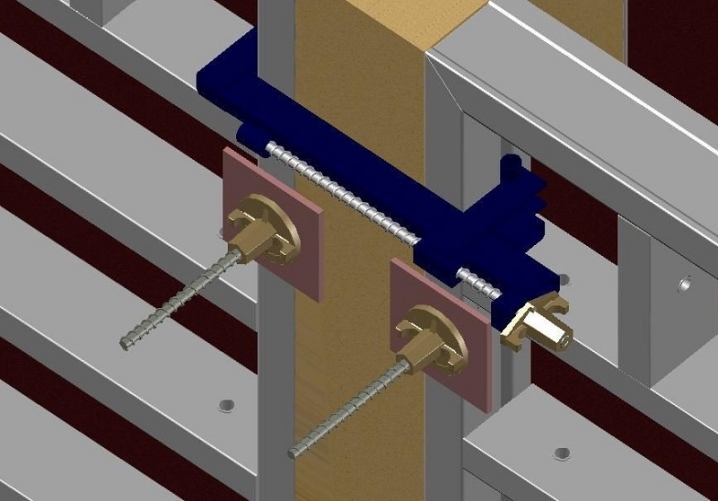

Installation technology

Iron formwork panels are fixed with locks with a step that can give the entire structure the required stability, taking into account, along with this, the indicator of the pressure exerted on each square meter of the poured concrete mixture. To make the fasteners more reliable, holes are drilled in the sheets, which are intended for mounting the clamping legs. In addition, the strength of the formwork is increased by transverse timber beams mounted at the points of the lock joints throughout the entire area of the structure to be assembled.

The pressure from the clamp is distributed by means of the cross beams, and the local deformation of the iron sheets is eliminated. It is well known that fasteners are required when constructing any formwork system, on the design features of which the installation procedure depends.

The procedure is as follows:

- formwork panels are installed in accordance with the terms of design solutions;

- their initial alignment is performed;

- locks are installed;

- final adjustment of the structure is carried out and it is tightly pulled together.

Installation of spring clips:

- install reinforcement rods in the holes, they should extend beyond the boundaries of the formwork by about 15 centimeters;

- put a clamp on the protruding end of the bar;

- push it close to the shield;

- put the key on the clamp, fixing it with a small lever;

- turn the large lever and secure the clip.

Dismantling the formwork clamps

When using formwork systems in the construction of monolithic reinforced concrete structures, it is necessary not only to know the methods of their installation, but also to be able to carefully disassemble the structure in order to use it in the future.

Dismantling work is started as soon as the concrete mixture has finally hardened and has accumulated the required strength factor. First of all, the fasteners are dismantled, then the algorithm of actions is as follows:

- when using a wedge clamp, the wedge is released by means of a hammer, the clamping jaws are removed;

- when the connection was made with a spring clip, it is required to dismantle the clamping parts, leaving the reinforcing bar in the concrete, and cut off the protruding pieces of reinforcement;

- in the screw connection, the nuts are simply unscrewed.

Removing spring locks

After the concrete mixture has hardened, hit the “frog's” tongue with a hammer and dismantle the clamp. Cut off protruding parts of the bar.

Having removed the locking elements, they begin to carefully disassemble the shields in order to move them to another area of work.

The comment was sent successfully.