Polyurethane adhesive: characteristics and application features

The modern market offers a wide range of adhesives that allow you to get a strong and reliable connection of various objects. But many of them are designed for specific actions and materials, which is not "to the liking" of the buyer. Popular is a polyurethane compound, which is distinguished by its versatility and is used to work with any materials.

Peculiarities

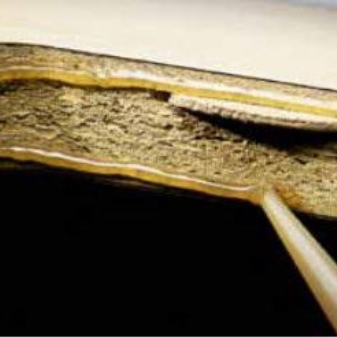

Almost the entire composition of polyurethane glue is solid synthetic resin, which distinguishes this mixture from all analogues. In them, resins are only a small part of the composition, everything else is water. A special feature of a polyurethane product is its hardening. On contact with water vapor, it enters into a chemical reaction, resulting in a strong film. Also, during the reaction, carbon dioxide and bubbles are released, which makes the polymerization process similar to the drying of polyurethane foam.

A distinction is made between two-component and one-component polyurethane adhesive. The second consists of isocyanate prepolymers, is easy to use and allows a large amount of work to be done quickly. It has a high viscosity, due to which any material instantly adheres to the required surface.

Two-component contains two substances, which in an unmixed state have a low viscosity. And only after mechanical mixing does the glue take on its working state. The mixing procedure for the components requires specific temperature conditions and specific proportions.

The polyurethane composition has a number of advantages, due to which it is in demand among buyers.

- resistance to high humidity - this mixture can be used even on the streets for garden furniture, which is used all year round in any weather;

- reliability and strength - the glue guarantees a high-quality bond when joining different materials, even damp wood or covered with all kinds of antiseptics;

- open exposure time - when working with polyurethane glue, you do not need to rush at all, for about 20 minutes you can carefully apply the composition and apply all the details with precision;

- comfort during work - the glue ensures the sliding of the lubricated elements, which is convenient when assembling tight structures;

- it is appropriate to use for laying parquet - the mixture firmly fixes the tree to the floor and prevents the material from swelling.

For working with wood, as a rule, a one-component version is used. Two-component is usually used for moisture-proof materials - plastic, glass.

Specifications

Polyurethane hot melt adhesive is a viscous liquid that can be gray, white or amber. A hardener container is included with the two-component mixture. The glue is sold in plastic or metal buckets up to 5 kg. The polyurethane-based mixture has excellent mechanical properties.

You can work with the mixture in conditions with temperatures from 0 to +40 degrees, and after pasting, the composition can withstand from -50 to +120 degrees. Please note that for good adhesion, the surface must be thoroughly cleaned of dust and dirt before applying the glue, as well as degreased.

The properties of the glue also include the prevention of the formation of mold and mildew. During application, the mixture foams a little, due to which the space between the two materials is completely filled with the composition.For the production of glue, no solvents are used, it is odorless, which has a positive effect on human health and the environment.

The polymer composition contains a hardener, which makes it resistant to adhesion. The consumption of glue directly depends on the material and ranges from 150 to 500 grams per square meter.

Manufacturers

Consider the most popular polyurethane formulations.

- Soudal - this option is sold in aerosol, it is easy to use. The adhesive fixes foam panels and gypsum plasterboards with high quality. The mixture dries up in just an hour and is consumed economically.

- Polynor fixo - heat-insulating adhesive, used for joining plates of expanded polystyrene, polyurethane foam and mineral wool for thermal insulation of a building. It is sold in an aerosol can, therefore it is easy to use.

- "Moment Crystal" - glue of a domestic company, designed for working with plexiglass, rubber, metal and other materials. Resistant to moisture and alkalis.

- "Desmokol" - a solution of polyurethane rubber in organic solvents. With its help, you can get a durable seam that will not be afraid of moisture and temperature changes. The indisputable advantage is that this composition dries very quickly.

- Mapei - tile adhesive from an Italian manufacturer.

These mixtures are offered at different prices, the choice of the composition depends on the operating conditions, as well as on the materials that it must glue. Experts recommend buying the mixture in large hardware stores, where you can compare prices from different manufacturers, study the composition of the glue and its operating conditions.

How to choose?

When buying glue, not only polyurethane, special attention should be paid to its characteristics. Even the smallest details must not be overlooked.

- The time that the applied glue retains its elasticity - during this period, you can carefully apply the composition, remove excess, qualitatively adjust the glued elements of flexible metal or wood. That is why novice specialists are advised to choose formulations with the highest given indicator. Quick drying materials will be a lot of hassle.

- Flow rate - this property is important to consider in two situations: when gluing tiles on vertical surfaces or in the presence of a base with many disadvantages, such as pits or bulges. Too thick composition does not spread over the material, accordingly, it does not fall into all voids, and high-quality adhesion is not guaranteed, no matter what material it is - PVC, SIP panels, expanded polystyrene or ceiling plinth.

- Shelf life for application - this property is taken into account when buying two-component adhesives. After mixing the two substances for several hours, the glue retains its properties. The amount of the prepared solution depends on the time after which the composition loses its characteristics.

- Scope of operation - some solutions are best used for aerated concrete or parquet, and some for sandwich panels or stone. Some mixtures are suitable for stucco molding on curved surfaces, gluing cornices to ceilings, while others are suitable for high-quality thermal insulation from inside or outside the room.

Application Tips

To achieve high-quality and reliable gluing of surfaces, you must follow all the rules and recommendations of specialists. Thoroughly clean all elements from dust, dirt and treat them with a degreasing agent. The glue is applied in a thin layer using a brush, spatula, spray gun, or special equipment, if we are talking about manufacturing enterprises.

Please note that excess glue may spill onto a clean surface. In order not to worry later about how to remove the dried composition, it is better to remove it immediately with a special solvent.

Different materials can be glued using different technologies.

- Hot method - it is used with Desmokol glue, the solution is applied to both objects and left for half an hour.The properties of the substance are activated under the influence of high temperature (approximately 85 degrees) within a few minutes. After this, the surfaces must be strongly pressed against each other.

- Cold method - to glue objects, you need to apply the mixture to both surfaces, after 10 minutes, reapply the glue in a thin layer, dry for a few minutes and connect the elements.

- Moistening the surface - for high-quality adhesion, the glued elements are sprayed with water and pressed against each other. This method is appropriate to use when there is a special press, since it requires the strongest possible compression.

It is necessary to work with glue in special clothing, a respirator and goggles.

In winter, the polyurethane composition does not lose its characteristics, but it becomes more viscous, so it is more difficult to work with it. Many people believe that it can be diluted or constantly heated, but experts do not recommend doing this. The optimum temperature for working with glue is +20 degrees. Therefore, if you are working at low temperatures, it is better to heat the barrel once and pour the glue into small containers that close tightly.

Note: containers with glue should not be kept near an open flame, much less heated over a fire. To maintain the optimum temperature, it is recommended to store the glue in a thermos. Do not heat the product above +40 degrees, and do not glue hot surfaces. If the objects to be glued have a temperature higher than +80 degrees, the glue will harden faster and its adhesion will increase.

If at the end of the work you still have the composition in the container, squeeze the bottle and close it tightly so that all the air comes out of it. This will prevent rapid deterioration of the substance, and it can be used more than once.

Polyurethane adhesive has been successfully used in construction and renovation. Its indisputable advantage is that even beginners can work with this mixture.

For information on how to use polyurethane glue, see the next video.

The comment was sent successfully.