Choosing a gun for liquid nails

"Liquid nails" (Liquid Nails) - construction and assembly glue, which is suitable for connecting all kinds of things by gluing. It is called so because when using it, the parts and surfaces are very firmly glued to each other, as if they are connected with nails. "Liquid nails" are a mixture of polymers and rubber. They are supplied to the market in the form of tubes of various capacities from 200 to 900 ml. For ease of application and uniform dosing, experts recommend using a construction gun. How to choose it correctly, and what to look for, will be discussed in the article.

Main types

Guns for "liquid nails" come in 2 varieties:

- for professional use, for example, for a 2-component composition;

- for household use (mechanical version).

The first are subdivided into:

- rechargeable;

- electrical;

- based on pneumatics.

Rechargeable devices are good for their autonomy. They function using a Li-Ion battery. Thanks to the handle, the glue comes out, you can also adjust its speed - the more you press, the more glue comes out. The only drawback is that you need to frequently charge the battery or change the batteries.

Electric gun differs from the wireless analog only in the absence of a rechargeable battery. The rest of the functionality is the same. Applying an adhesive to them is quick and economical. Usually such devices are used by specialists. Such a unit is worth a lot, therefore, for use at home, when there is no large front of work, the purchase is impractical. It is also quite difficult to insert the composition into the gun.

When the trigger is pulled under air pressure, the adhesive escapes from the air gun. Such units are very ergonomic, equipped with interlocks and controllers, so at the exit you can get an even strip of glue of the required width. His [gun] can be attached to almost any cartridge. Such a tool is used mainly in construction.

Therefore, for a small amount of installation work, they are used more often mechanical pistols, which are of 3 types:

- half-open;

- skeletal;

- tubular (in the form of a syringe) instrument.

The first variety is the most budgetary of all. However, there are also disadvantages: fragility and inconvenience of use. The mechanism is enough for only 2-3 cylinders. The support for the tube is not large enough, therefore, in operation, it [tube] is often displaced relative to its position, and this prevents the smooth movement of the rod.

But experienced craftsmen have found a solution to this problem - the container must be fixed in the tool body with adhesive tape, wrapping it around the balloon next to the handle. The main thing is to keep the device manufacturer's sticker intact, since the unit has a warranty, and in case of a malfunction it can be returned.

The skeletal type is the most popular with buyers. It is a little more expensive than the previous one, but it fixes the tube with glue more reliably, thanks to which the application of "liquid nails" is more uniform.Scotch tape is also used to securely fasten the cartridge, because the bodies of budget pistols are made of aluminum, and this does not allow the tube to be fastened tightly enough.

The most practical option is the tubular type. It securely fixes the cartridge and is used not only for applying "liquid nails", but various types of sealants.

Pistols come in sheet or with a frame. The latter option is more reliable, because in it the cartridge is tightly attached to the platform. The tool can be equipped with a reversing function: this option is very important for home use. Thanks to the reverse, you can change the tube with the adhesive to the container with the sealing substance. In the case when the option is absent, the tool is used until it is completely empty.

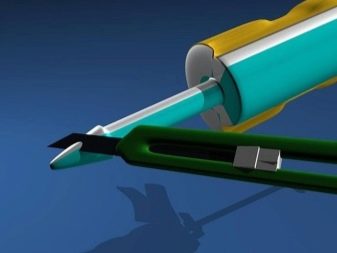

What the assembly gun consists of

The main components of the tool:

- platform for fixing the tube;

- handle (rubberized in some models);

- landing lever;

- kernel;

- disc (piston), which is attached to the rod;

- tongue for locking (fixing).

The sequence of work with the mechanism is as follows: first, the tube is installed on the platform and fixed, after pressing the trigger, the rod is activated, which then pushes the piston. It presses on the bottom of the cartridge and squeezes the adhesive through the hole in the tip to the surface.

In expensive variations, after the hook is released, the rod moves back a little. This reduces the pressure in the container and minimizes the risk of excess adhesive leaking out.

Advantages and disadvantages of the pistol

The positive aspects of using this tool include the following:

- uniform application of glue to the surface;

- the ability to introduce an adhesive even into hard-to-reach places;

- ease of operation, even a beginner can handle;

- the special design prevents "liquid nails" from getting on the skin and other surfaces.

Despite the advantages, the unit also has disadvantages:

- the high cost of a quality tool, for example, electric or battery;

- at the end of the installation work, the device must be constantly cleaned, therefore, a special cleaning agent is needed;

- When working with a rechargeable device, you need to frequently charge it or change the batteries.

Description of the device functioning process

First, you need to figure out how to properly place the balloon with "liquid nails". It is unacceptable that the tightness of the packaging was broken in case of improper installation, otherwise the glue will dry out, and it is unlikely that it will be possible to use it.

Before using the gun, you need to prepare the following things:

- balloon with "liquid nails";

- sharpened knife;

- glasses and gloves for protection;

- breathing mask, if you plan to use an adhesive mixture prepared by yourself;

- dry cloth to remove excess adhesive;

- solvent, due to the fact that glue can accidentally get on the skin or any surface.

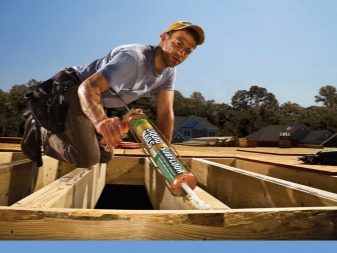

The principle of operation of the tool is quite easy - after the pressure is applied to the balloon mechanically, the adhesive "comes out" of the balloon. The pressure is provided by the rod, which is activated by acting on the release lever. In assembly units on a pneumatic basis, the pressure is supplied by air. Difficulties arise when you need to choose the appropriate glue. As a rule, manufacturers use the same standards, that is, you can choose glue for any gun.

If you are using a skeletal or semi-open pistol, the removal of blockages is quite quick. To begin with, check if there is a special restrictive bottom on the bottle with "liquid nails". If it is, delete it.

Next, pull the rod out of the device, for this you mechanically act on the lever and remove the rod.Instead, install the tube and press the trigger lever 2-3 times with a little effort to strengthen the cylinder.

Pierce a hole in the container, glue will flow through it to the tip.

If you decide to use a tubular tool, then it is refueled differently. First you need to make a hole in a bottle with "liquid nails". It is necessary to fix the balloon with the adhesive so that the cut end of the balloon is directed to the tip, from where the glue will "come out". Before installing the cartridge in the tool, you must remove the stem.

As a rule, the kit comes with several nozzles with tips, with one of them you twist the cylinder. If there is no hole on the tip, then you need to cut off a very small part with a knife at an angle of 45 degrees. Then gently press the trigger and move the glue along the markings applied in advance. If you are using a skeletal or semi-open instrument, then in order to fill the void in the cap, you must first press the trigger several times, and then perform the actions smoothly.

In electric and battery-powered machinery, pulling the release lever controls the release rate of the adhesive, so if you have never used such a complex machine before, it is better to start in subtle areas.

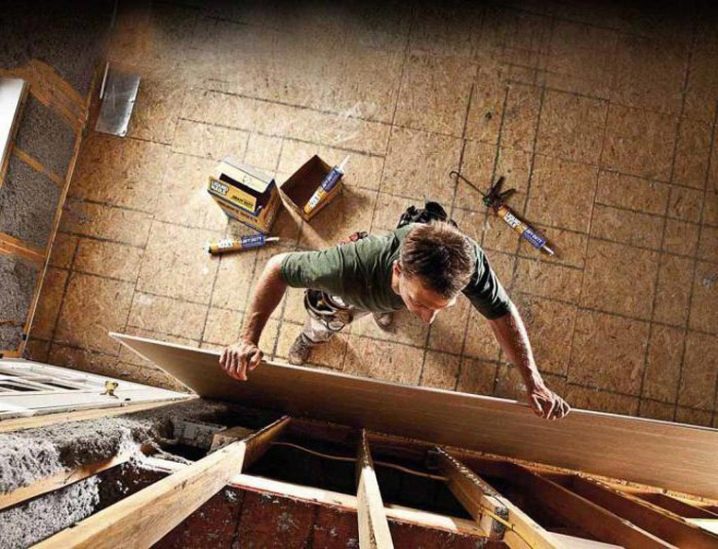

Before the bonding procedure, the surfaces must be cleaned and degreased. Then apply "liquid nails" in a thin layer or in dots. In the case when the surfaces to be glued have a large area, for example, ceramic tiles, then it is necessary to apply the adhesive on them in the form of a snake or mesh. After the surfaces to be glued, you need to press against each other, if there is a need, then it is worth fixing them with special structures. Flat pieces can be placed under the press. Some types of glue set within 1-2 minutes.

As a rule, complete adhesion of surfaces occurs after 12 hours, sometimes in a day.

Instrument Precautions

The actions with the gun must be done very carefully so that the glue does not get on the skin or any surface. Apply a small amount of "liquid nails" along the pre-marked areas.

If drops of glue hit the mechanism, it must be rinsed immediately, without waiting for it to dry. Cover the tip of the cartridge with the protective cap to prevent the adhesive from drying out. If this is not done immediately after application, the product will deteriorate very quickly, and you will have to throw away the partially used balloon.

At the end of the work, remove the container from the pistol, and rinse the mechanism in soapy water and leave to dry. To remove the used balloon, press the locking tabs and pull out the rod with the piston. Then remove the container.

If the glue gets on your hands without waiting for it to dry, you must immediately remove it. An organic-based adhesive cleans well white spirit, acetone, water-based - it will be enough to rinse with plenty of water.

Which mechanism is better to choose?

Before choosing one or another assembly gun, you must first decide on the area of future alterations. For example, if you need to glue a small area, a skeletal tool will suffice. If the task is more difficult, for example, you are going to carry out repairs in the entire room, then it is recommended to buy a pneumatic-based mechanism. It is better to choose a frame gun, because in this case the bottle with "liquid nails" will be better attached to the platform. It is also worth paying attention to whether there is a reverse function.

Who cares about the speed of execution and the accuracy of the application should take a closer look at an electric tool or one that runs on a rechargeable battery. Before buying, hold the mechanism in your hands and check if it will be convenient to use it in the future, and if any details interfere.Particular attention should be paid to the trigger, what material it is made of. It is preferable if it is made of aluminum. When choosing a brand, you should first look at the products of those manufacturers who are trusted by the majority of users. It will not be superfluous to read reviews on the Internet.

Based on all of the above, the following conclusions can be drawn:

- The assembly gun is an irreplaceable thing when applying "liquid nails". The process takes less time than if you applied the adhesive without tools.

- When choosing, you should be guided by the scale of the upcoming installation and construction work. If it is small, then it is better to use a mechanical pistol.

- When working with "liquid nails", you must take precautions, wear protective goggles and gloves.

- In general, even a beginner can figure out how the mechanism functions. In extreme cases, there is always a manual included.

How to choose the right gun for liquid nails, see below.

The comment was sent successfully.