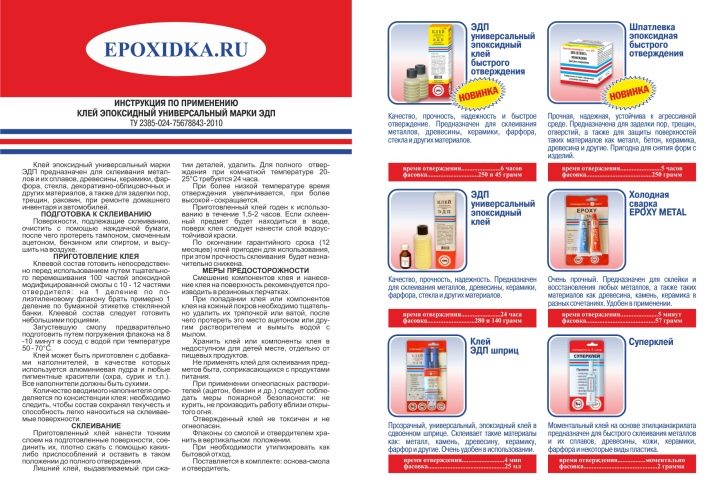

How to dilute epoxy adhesive: the right proportions

Very often, both in everyday life and in production, means for gluing materials are required. Epoxy glue is one of the most commonly used types of adhesives and has many advantages. But like any product, epoxy glue has its own characteristics that affect the final result.

Peculiarities

Before proceeding with the gluing of surfaces, it is necessary to understand the composition of this glue, the principles of its action and the field of application.

What does epoxy glue consist of? The answer to this question lies in the name of the glue itself. It is based on epoxy resin, which is a type of synthetic resin and has universal consumer properties.

The resin requires a certain temperature regime to cure. For epoxy resin, it ranges from -10 to +200 degrees. The choice of temperature depends on the type of composition. Depending on the temperature at which the reaction will take place, epoxy resins are divided into cold and hot curing types. The cold look is used for materials that are not subject to heat treatment, and the hot types are needed for materials that can withstand not only high temperatures, but also exposure to active chemicals.

Cold curing is most often used for bonding materials at home, and also used in small industries. For large industrial plants, hot curing is the most suitable. Aircraft, mechanical engineering, electrical engineering, radio electronics, shipbuilding and other industrial areas use epoxy resins in the composition of the adhesive.

In addition to epoxy resin, the glue contains a hardener; without it, the polymerization process is impossible. It is the hardener that, having reacted with the epoxy resin, helps it harden and not melt.

On sale, the resin and hardener are in different bottles; for gluing, these components will have to be diluted in the required proportion. Both components belong to polymers with a small molecular weight, when they interact, simple molecules combine, resulting in a large polymer molecule (when completely solidified).

To speed up the polymerization process, you can increase the temperature and increase the amount of hardener, and to slow down the reaction, do exactly the opposite, lowering the temperature and reducing the amount of hardener.

The universal composition of epoxy adhesive is characterized by a high degree of adhesion, they can glue almost any materials: metal, rubber, glass, plastic, wood, the main thing is to combine resin and hardener in the right proportion. After complete hardening, the surface treated with this composition can be subjected to any processing: grinding, sawing, drilling and other types of work can be carried out without deforming the material.

How to breed?

Dilution of glue requires the utmost care, so it is best to prepare all the necessary tools and protective equipment in advance.

Rubber gloves and a mask will be required to protect the skin and respiratory tract, because both components are extremely toxic substances. you need containers for diluting the components and sticks for mixing them. In addition, the room in which the work will take place must be well ventilated.

Depending on the composition, epoxy can form compounds of different rigidity.For a soft elastic hitch, one type of compound is produced, and for a hard one, it is completely different. Therefore, it is necessary to purchase components and prepare an adhesive composition, strictly observing the proportionality indicated by the manufacturer.

Typically, the resin and hardener vials come with instructions., which always indicates how to mix the components correctly, while observing the proportionality of the dilution. As a rule, to prepare an adhesive, it is required to dilute the components 10: 1 - for 10 parts of resin there is 1 part of a hardener.

But manufacturers today produce different compositions that do not always need to be diluted in this way, sometimes in order to prepare an adhesive composition, it is required to mix resin and hardener in a different proportion.

The proportion of dilution depends on the specific manufacturer. In one case, the ratio can be 10: 4, in the other - 10: 6, and in the third, to achieve the desired consistency, you need to dilute 4 parts of the hardener in 6 parts of resin. The proportion of dilution depends not only on the specific manufacturer, but also on the release date of the resin and hardener, storage conditions, ambient temperature, and, of course, on the quality of both products.

Previously, in order not to be mistaken with the amount of added components, manufacturers produced bottles with marks, but today there are no divisions on the bottles, so mixing the ingredients can be done using different improvised means.

To mark a small amount, you can use an old pen from under the pen. Before use, it is thoroughly washed and marks are applied to the surface at regular intervals.

You can measure the amount of a component using a more convenient tool - a syringe. There are already marks on it, you do not need to draw them yourself, and they are applied much more accurately than those made with your own hands on the rod. To pour the hardener into the syringe, you just need to remove the needle and pump it through the piston, and the resin will have to be placed in it in a slightly different way, because it will not work to draw it through the spout - it has a consistency that is too viscous. In the syringe, it is necessary to remove the needle, remove the plunger and plug the nozzle, and only then pour the resin through the top.

In order to properly mix the epoxy, you first need to prepare each component for dilution. A measured amount of a viscous transparent resin is added to the container and mixed thoroughly. Sometimes the epoxy resin is mixed very hard, therefore, to facilitate this process, it can be heated in a water bath, 50-60 degrees is enough. But it is worth remembering that an increase in temperature not only facilitates mixing, but also accelerates the polymerization process - you just need to increase the temperature of the mixture by 10 ° C, and the reaction will accelerate 2-3 times.

After preparation, the components must be combined and stirred in a clean container, but this must not be done very vigorously, otherwise bubbles cannot be avoided. Their presence in the glue can spoil the appearance of the poured objects if the composition is used as a fill.

For simple gluing of surfaces, the number of bubbles does not really matter. If dyes are added to the composition, then it is better to use them dry, since moisture, even in a minimal amount, negatively affects the adhesive composition.

The prepared composition during the first minutes has a liquid consistency, but after 10-15 minutes it begins to thicken quickly, and after 30 minutes it hardens. To extend the time of working with the composition, you can use a tool such as acetone - it will increase the duration of the glue up to 1 hour. To do this, you need to dissolve only 1 part of this substance in a composition with a ratio of 10: 1: 1.

How to use?

It is not enough to properly prepare the composition, you also need to skillfully use it.The glue can be used both as a surface connector and as a pouring into prepared molds.

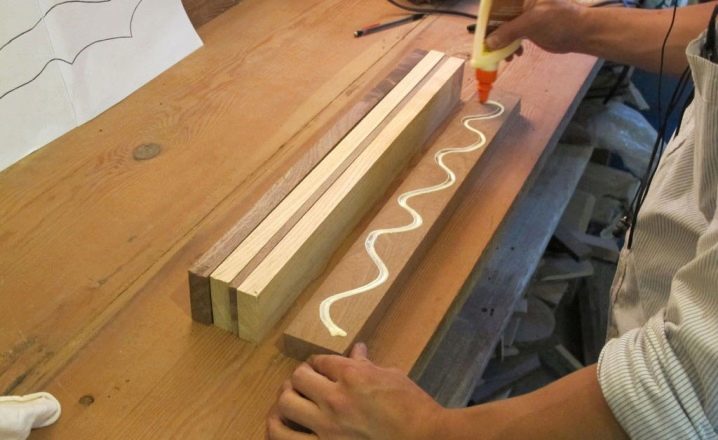

For durable bonding of materials, there are general preparation rules:

- mechanical cleaning of the surface of materials from contamination;

- degreasing the prepared gluing sites from oil traces; for this, a solvent, acetone or detergent is suitable;

- surfaces with a gloss are processed using sandpaper or a grinding wheel.

For simple gluing, the composition is applied to one of the sides, after which both surfaces are pressed tightly against each other. You can use a strong rope, vise, clamps or weight as clamps. The remaining glue residues are removed with a dry cloth or napkin. The glued materials should be in a fixed position for at least 24 hours while the primary polymerization process is in progress, after which the auxiliary fasteners are removed, and the glued product is left to dry completely for 7 days.

When using special filling forms, they are prepared differently. The bottom and sides are treated with fats. After lubrication, the finished composition is poured into a mold and kept in it until complete curing. To increase the speed of polymerization, after 3 hours of keeping the mold at room temperature, it is sent to the oven for heating. If the mold is not heated, the complete curing process can take up to 7 days.

Advice

When preparing the composition, as well as when applying it to the surface or pouring this glue into forms, there are universal tips to help achieve better gluing.

When preparing the composition, it is better to use dishes and auxiliary tools that are unnecessary for further use. It is almost impossible to clean them of such a composition, so all used containers and tools for mixing will go to the discard.

Pouring into the mold must be carried out in stages, especially if it is planned to make the layer thickness more than 2 mm. After the first coating has cured, the next batch is poured only after the layer has cured, but with a sticky surface.

For large volumes, it is better to buy special formulations.not subject to overheating. When mixing large quantities of ordinary glue, there is a risk of fire in the composition. Therefore, for your own safety, you need to calculate in advance the required volume of the mixture and buy glue, calculated specifically for this volume.

For information on how to properly dilute epoxy glue, see the next video.

The comment was sent successfully.