All about trapezoidal taps

Specialists in workshops and ordinary people should definitely know everything about trapezoidal taps, about the GOSTs related to them. Noteworthy are taps 16x4 mm and 18x4 mm, 12x3 mm and 22x5 mm, 12x2 mm, 20x4 mm and other sizes, as well as their use in practice.

Characteristic

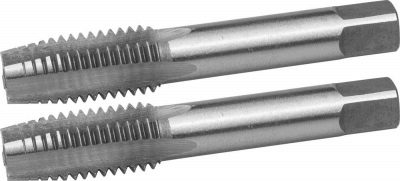

Trapezoidal tap is designed to perform specific (trapezoidal) threads... This tool is quite popular with professionals and hobbyists alike in the machining field. There are both single and complete products for technical marking. These fixtures are suitable for both solid and through holes.

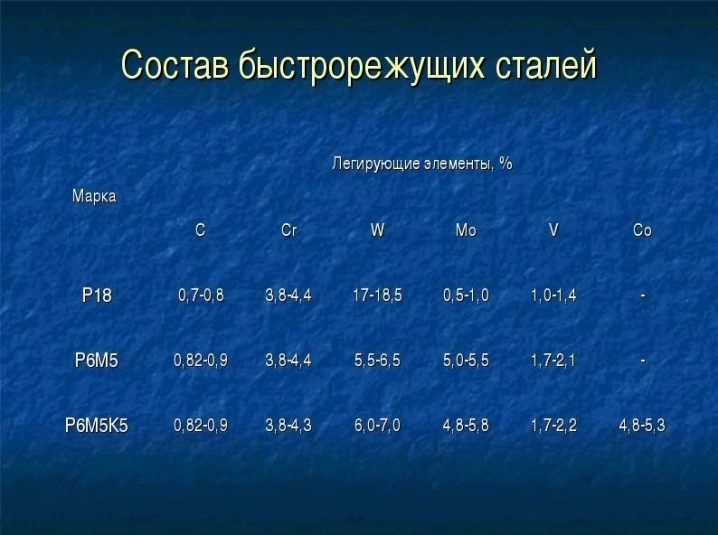

Basically, high-speed steel is released for the manufacture of taps, because the processing speed is more important than the efficiency factor.

Trapezoidal thread:

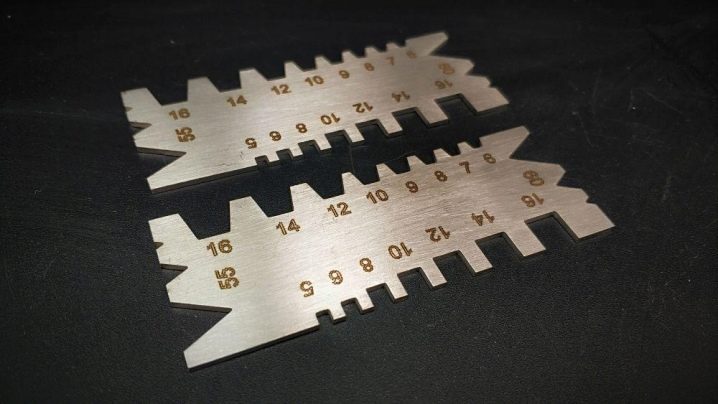

- differs in the nominal cross-sections from 0.15 to 4.8 cm;

- maintains a gap between adjacent sections of the profile of 0.075-0.24 cm;

- has an average profile angle of 30 degrees;

- has a maximum gap width of 0.05 cm.

Dimensions (edit)

Trapezoidal taps are produced in accordance with GOST 19831, adopted in 1974. The standard specifies the tolerances for making grooves that meet the technical requirements. Accuracy grades - H5, H6.

Machine-hand tap 12x2 mm is in demand. It can be supplied in sets of 2.

Usually such products:

- have the right direction of the grooves;

- have a thread pitch of 2;

- are made of the proven alloy P6M5.

Trapezoidal taps 12x3 mm are also good. For example, one of these options:

- intended for machine use;

- weighs 0.065 kg;

- obtained from alloy P6M5;

- suitable for handling alloy steels;

- has a cutting edge of 6.5 cm;

- is performed with the right groove.

The marking device can also have a dimension of 16x4 mm. It mainly works in pre-prepared aisles. Since the main part of the work takes place with metal, the tool is made from a durable alloy. The design is calculated for the reliable fixation of the fixture in the lathe.

The tail part corresponds in shape to a regular parallelepiped.

You can also buy taps:

- 18x4 mm (single pass type, 22 cm long and 0.4 cm threaded pitch);

- 22x5 mm (based on the HSS-G, with a total length of 17.5 cm and with a working area of 6.5 cm, with a drive square of 1.2 cm);

- 20x4 mm (rough from HSS-G, with a 1.1 cm drive square and a 1.4 cm shank section, with a total length of 16 cm and a functional section of 5.5 cm).

Application

For trapezoidal threading, it is quite reasonable to use the same trapezoidal taps.... This thread is often used to make various screws. And screws are already used in machine tools, presses and lifting machines. Trapezoidal threads are easier to cut than other types.

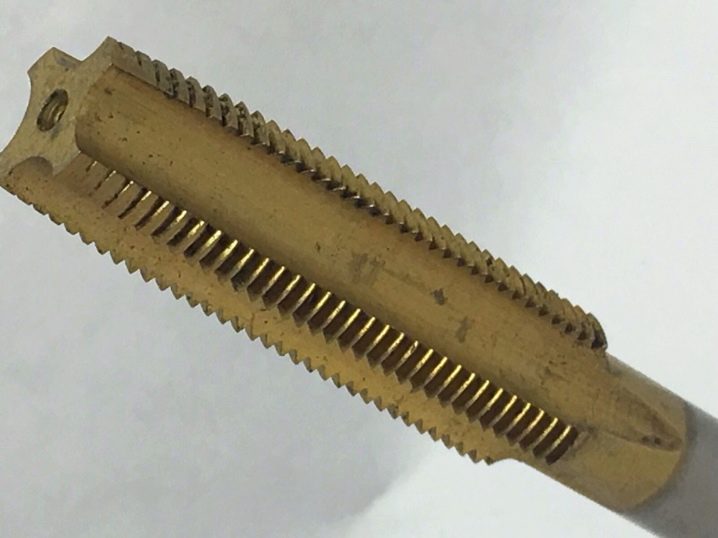

Some models of taps are designed for broaching, they are called so - broaching taps.

This type of marking equipment has a higher level of tolerances. It is used to pre-process shaped holes with large profiles (screw-shaped). They usually try to choose a shank larger so that it holds an increased load. Taps shape and finish holes in:

- machine parts;

- parts of household mechanisms;

- building structures (including those made of carbon strong steel).

The comment was sent successfully.