Sets of taps and dies

Taps are used to calibrate and apply internal threads to workpieces and parts. Dies, respectively, are used for sizing and cutting external threads.... To apply a thread, a specialized tool is required; it will not work to replace it with a similar one, although the principle of operation is similar for everyone.

Therefore, home craftsmen need a whole set of taps and dies. There are a number of other devices for making threads on parts and workpieces. They are more suitable for mass production. And for home use, taps and dies are suitable.

general description

Threaded connection is considered one of the most effective and reliable ways to connect two parts. It not only securely holds the parts together, but also allows you to separate them later if necessary. To create a threaded connection, you must thread both parts. And this requires special tools. Taps and dies are special hand (machine) cutting tools. Tap and die sets are useful for tapping parts or pipes, for example. Professional kits for creating threads include several types of taps and dies (sometimes called lers).

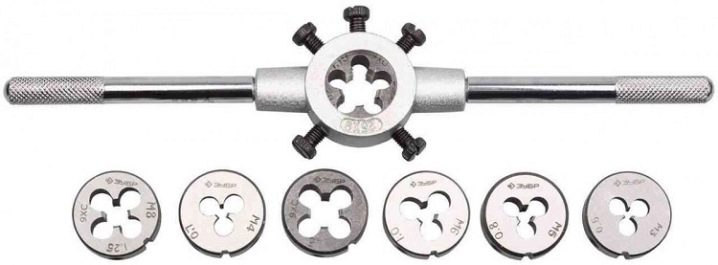

Dies (sticks) are used to create external screw threads... Previously, dies and sticks were considered different instruments, now they have been combined. Lerka is a non-separable one-piece tool, and the die can be disassembled and adjusted. Some craftsmen believe that the lerka makes better quality carvings. The die looks like a large nut with several holes with a cutting edge, which create a screw thread.

The dies must have side holes (from 3 to 6), they are necessary to remove the resulting chips during operation. You can cut an external thread with a die either manually or using a machine.

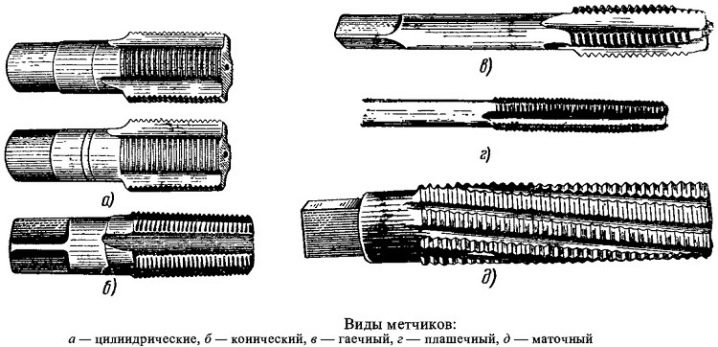

Taps are needed for internal threading... For example, to repair stripped threads on nuts or studs. At first glance, the tool resembles a screw and looks like a rod with a cutting edge. Edge slots can be helical or straight. The tap consists of a working and a tail. The working part is divided into 2 zones: cutting and calibrating. The cutting zone is tapered with longitudinal (sometimes helical) grooves.

The calibration zone continues the cutting and has a cylindrical shape. On the cutting part, you can see teeth of various shapes, which set the parameters of the thread. The quality and accuracy of the processing of the teeth will determine the quality of the threads they apply. With the help of a shank, the tap is attached to a special machine (machine version) or a tap (manual version).

By performing rotary movements with the cutting end, the tap gradually forms an internal thread in the part or workpiece. To increase wear resistance and productivity, taps are made from hard alloys or high-speed steel. High speed steel speeds up and facilitates the process of creating threads several times. In the process of work, make sure that the chips are removed from the hole in a timely manner: this way the tool will last longer, and the cutting edge will remain sharp.

To improve the quality of the threads, select the correct tap sizes. Sometimes it is better to use multiple taps to create a new thread.

Species overview

This set of tools without exaggeration refers to irreplaceable, it has no analogues... Devices can be useful in construction, renovation and carpentry. With their help, you can restore the broken thread on a bolt or nut, apply a new one on the desired area of the part.

On the market, there are most often 3 types of dies by type of design:

- split;

- whole (lerka);

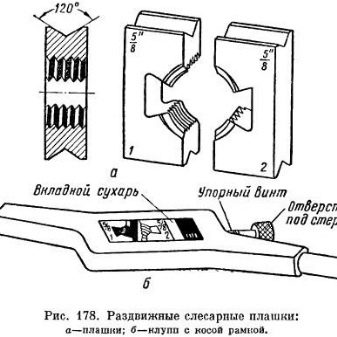

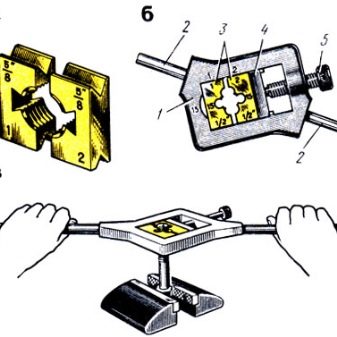

- sliding (kluppovye).

Solid models are used when it is necessary to obtain the highest quality threads. Ideal quality is achieved due to the high stiffness of the die. This type of dies has one significant drawback - a low indicator of wear resistance.

If there is no need for high quality threads, then split dies can be used. When used, such models are springy, because of this there is a high probability that the thread diameter may change slightly or bend. This is due to the low rigidity of the material of the split dies. The result of the work is imperfect.

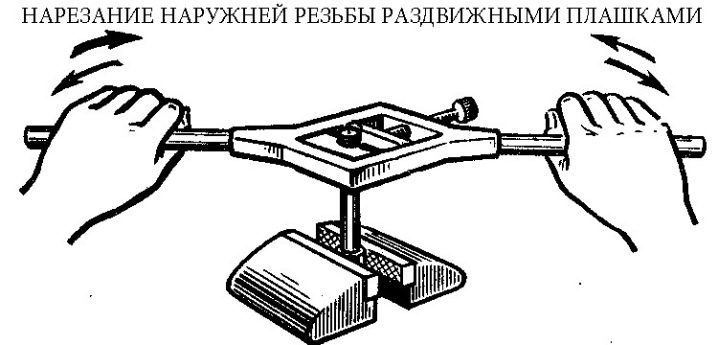

Sliding dies allow you to select the thread size yourself. They are most often found in sets. There are models of dies that allow you to make a left-hand thread, that is, a thread in the opposite direction. Oddly enough, but such tools are also in demand among craftsmen. They are called so - left dice.

Depending on the standard used, dies can be divided into metric and imperial. In the domestic market, metric options are more common. Professional kits often include pipe dies. They are designed to create cylindrical threads on pipes and tubular parts. Such a thread is necessary for their reliable connection. They have a distinctive feature - the presence of special pipe leads and holders with a ratchet.

Taps in tool sets are more often machine-hand. They are considered versatile, suitable for work both on machines and using a wrench at home. Conventional hand taps are suitable for woodworking joinery. The accuracy class of the applied thread is low for such options. Machine options create threads much more accurately and are suitable for metal work.

By specialization, taps are divided into

- nut;

- spot;

- special.

As the names suggest, nut taps are used for threading nuts... In production, they are used on machines where a large number of nuts are processed in one go. The die tap will help to correct (calibrate) the threads in the dies. Special taps are used in narrow-profile work. They are distinguished by the type of tips and the shape of the threads that they can apply. Here you can find round, conical, trapezoidal, pipe, adjustable, prefabricated and many others. Each of them is used only in a specific situation, which depends on the type of material of the product and the functions of the tool.

The set includes 3 to 5 taps to create threads of the same size. They are divided into roughing and finishing tools. In this case, all taps are divided into 2 types: for through or blind holes. There are taps for both right-hand and left-hand threads.

According to the system of standards, taps, like dies, are metric and inch... The M mark on the shank of the tap means that it is metric, the pitch is measured in millimeters. Manufacturers offer a huge selection of taps that will allow you to create threads of almost any type and size. The letter G stands for pipe taps, and the K defines the tapered type of tool.

You can choose the size of the tap for threading using special tables that are easy to find on the Internet. There you can calculate the shape, pitch and diameter of the hole and thread in the product or workpiece, which should be obtained using a specific tap. Standard tap sizes start at M2. In sets, taps with the size range M3-M12 and the corresponding step length are more common.M2 is extremely rare, if necessary, it can be purchased separately. The kits usually include 1 tap M3-M16, 2 each (roughing and finishing) with the size M6-M24. And in the largest sets you can find 3 taps M2-M52.

The most complete set with a rich set is considered to be a set from a Russian manufacturer of 110 items in a convenient plastic case. The tools are made of alloy steel with high bending strength. It includes 35 taps and dies, as well as additional accessories. There are also sets of 40, 65, 12, 36, 32 and 51 items on the market.

The variety of sizes and thread shapes will depend on the number of items in the set. The most common size ranges in kits are M3-M10 and M4-M14.

Top manufacturers

When choosing a set of taps and dies, you need to pay attention to several important parameters:

- quality;

- equipment;

- convenience;

- price.

Often, tools from cheap kits quickly fail, and the variety of size ranges leaves much to be desired. Also, some sets are not very convenient to use, do not have special holders in the kit, or storage cases are not provided for long-term use.

The best manufacturers of such sets are Russia and Germany. Their sets harmoniously combine price and quality. Producers from Germany offer small, high-quality sets at a very affordable price, suitable for home use. They contain the most common sizes of taps and dies, as well as special holders for them.

You can find economical options for beginners and professional kits for masters with an appropriate price from domestic firms. In most cases, sets consist of 30-40 pieces, this is the optimal number of tools with a sufficient assortment of size range and step length.

Often there are both metric and inch tools in kits.

Nuances of choice

To choose the right sets of dies and taps, first you need to decide for what purpose the tools are needed. The kits are professional and amateur. Amateur kits are suitable for everyday needs, the choice of tools in them is limited. And professional kits are more expensive, so it is better to purchase them when you need to use them every day.

When buying, pay attention to the type of tools according to the system of standards (metric or inch). Metric dies have a tapered blade. The tapered shape is the most common type of blade. And the rest of the tools differ only in the system by which the thread pitch is measured. When choosing, make sure that the thread on the die has a triangular shape, then the nuts can be screwed onto the restored thread.

Decide which set you need: machine or manual... With the help of hand dies and taps, threads can be made manually, without the use of additional devices and tools. This option is suitable for joinery work. And if you need to thread harder or more viscous materials of parts (for example, titanium alloys), then machine tools are needed.

Taps and dies should be made of high-strength carbon (or high-speed) steel or tool carbide alloys to increase wear resistance and speed up the work process. It is good if the set includes accessories (holders) for manual work with tools. The holder is made in a T-shape, which makes it easier to work with.

The holder must indicate the dimensions of the taps or dies for which it is suitable.

The comment was sent successfully.