What are corrugated sheets and where are they used?

Sheet metal is very popular in industry; corrugated sheets are widely used. The metal structures assembled from them and manufactured products are distinguished by a long service life and exceptional performance properties. We will tell you about what corrugated steel is, what its properties are, and where it is used in this review.

general description

Corrugated sheet is one of the varieties of sheet metal. Its characteristic feature is the presence of two different surfaces. One is standard flat and smooth. On the other, a corrugation of a certain shape is provided. This type of metal is subject to mandatory standardization and certification. The presence of one of the following defects on the surface is not allowed:

- mud;

- cracking;

- scale traces;

- rolled bubbles;

- ingot or rolled film.

Corrugated sheets have many advantages due to which they have found application in a wide variety of industries.

The surface of such sheets is non-slip - this plays a significant role in ensuring the maximum safety of the work and operation of the rolled metal. Due to the presence of grooves, the adhesion of the metal sheet with the rubber of the wheels or the sole of the shoe increases. As a result, the risk of injury to workers and damage to technical equipment on wheels is significantly reduced. In addition, movement on such a surface is more confident, due to which pedestrian traffic or the efficiency of employees on a covered area significantly increases.

Increased strength results in resistance to pressure and external mechanical stress... Another key characteristic of such rolled products is wear resistance. Even with intense exposure, the canvas will fully retain its anti-slip characteristics. The susceptibility to deformation and, as a consequence, the ease of processing allows the creation of metal structures of various sizes and configurations.

Oxidation resistance makes it possible to use rolled products in environments with high humidity. Corrugated sheet products do not lend themselves to aggressive media. As a result, the service life of the material remains high, even when the work is carried out under unfavorable conditions. Corrugated canvases look presentable and stylish. As a rule, such a flooring has a uniform silvery sheen, which looks harmoniously with the rest of the cladding and building materials. The aesthetic appearance eliminates the need for additional surface decoration.

The advantages also include a long service life and the possibility of using sheet metal after dismantling old structures.

Corrugated sheets are made from high-strength metal alloys, most often carbon steel... It is distinguished by its high load-bearing capacity and maximum load-bearing capacity. Such material is able to withstand falling objects and serious mechanical damage. It retains its integrity, does not deform and does not crack under temperature extremes.Thanks to this, the corrugated canvas has become widely demanded in large hangars and large warehouses - under the influence of oversized transport or heavy loads, the flooring maintains a stable level position and its functionality. Corrugated sheet metal is easy to maintain. It is easy to clean and easy to clean, which makes it possible to use it in facilities with increased sanitary and hygienic requirements, for example, in medical institutions. At the same time, to clean it, you need the most affordable means - soap, water and a brush with stiff bristles.

Features of production

For the production of corrugated canvas, carbon steel of grades StO, St1, as well as St2 or St3 is usually used, galvanized iron is in high demand... AISI 321, 409, 201, 304 stainless alloys are used a little less often. In industry, corrugated sheets made of ordinary steel are most in demand. Flexibility and increased strength make them durable and practical in comparison with the same concrete, which can crack and deform under the influence of mechanical damage. In areas where the decorative component does not play a role, sheets of black steel are often used - usually these are warehouse and production complexes. In other words, this option is optimal when you need to do "cheap and cheerful".

Production of corrugated duralumin sheets is allowed. The aluminum-magnesium composition of the AMg2 brand has become widespread, the magnesium content in it is 2-4%. It is a corrosion resistant alloy and is distinguished by its ductility. However, due to the reduced resistance to deformation and damage, such a material is not in great demand.

The hot rolling method is used to create corrugated surfaces.... This technology assumes the progressive heating of the steel sheet up to 1300 degrees. It is imperative that the temperature rise is gradual, otherwise the metal will crack. Further, the same smooth tempering of the metal is carried out and, if necessary, its galvanization. The workpiece prepared in this way is passed through a rolling mill with rollers. In this case, one shaft has a corrugated surface, the other is smooth. Exposure to high-temperature conditions makes the metal ductile, but the metal becomes weaker. In addition, due to the impossibility of uniform heating, the sheets may turn out to be uneven in thickness and width.

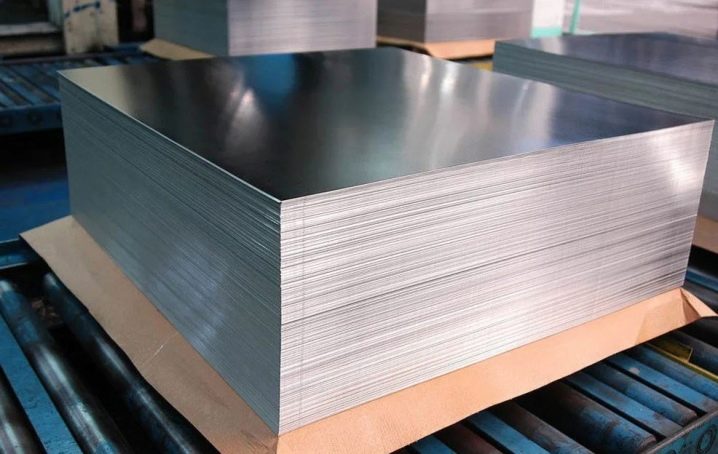

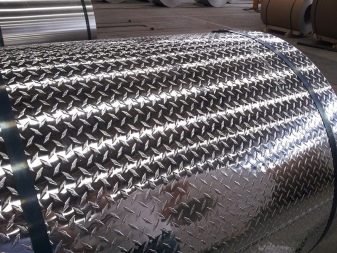

The cold rolling method is used a little less often.... In this case, no preheating is performed. As a result, the finished sheet acquires increased strength. True, its cost is much higher than the price of hot-rolled sheet. Corrugated steel sheets are produced in two types of delivery - in coils and also in sheets. At the same time, the thickness of such rolled products varies from 2.5 to 12 mm without taking into account the parameters of the fastening height. Rolled products are sold to trade enterprises with longitudinal edges without defects that could go beyond the established standards. In this case, the corrugation is placed at a predetermined angle to the surface of the sheet - usually 90 degrees. This arrangement provides maximum adhesion of sheet metal to any other surface.

Views

There are several reasons for the classification of corrugated steel. The most widespread division into groups, depending on the form and functional purpose of the material.

By appointment

Taking into account the scope of use, all existing options for corrugated sheets are conventionally divided into several groups:

- unmeasured in length;

- measured;

- multiples of the given parameter;

- measured length, if the remainder does not exceed 10% of the mass issued by the manufacturer of a certain amount;

- measured in multiples of length, if the remainder does not exceed 10% of the mass of rolled products of a certain amount.

By the shape and location of the riffles

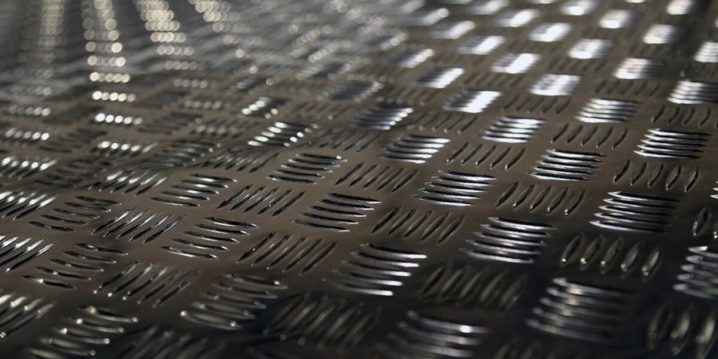

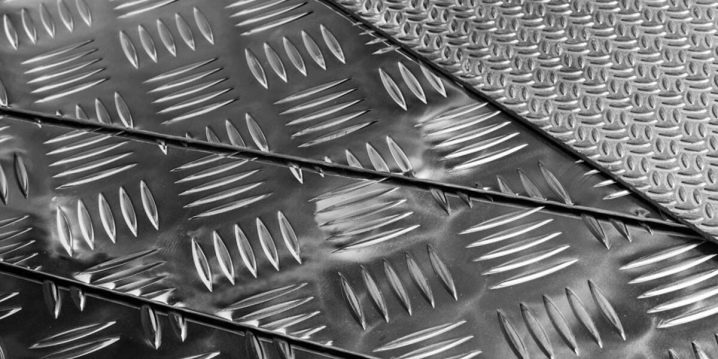

The rental can also be divided into 4 types depending on the pattern applied to the iron surface. Rhombus Is a classic, traditional type of corrugation. Such a pattern is usually represented by rhombuses with a side of 25-30 mm or 60-70 mm. Lentils - such riffles are more like the grains of this plant. They have a rounded, slightly elongated shape. The riffles are oriented at right angles with respect to neighboring elements of the pattern and are located at a distance of 20, 25 or 30 mm from the neighbors. The configuration of lentil webs can provide for both two riffles and five. In the first case, the sheets will be called "duet", in the second - "quintet". Some retailers offer options for "scales", "skin" and others. They belong to the decorative varieties of rolled metal. When purchasing such sheets, you must be aware that it was produced without complying with GOST standards, and can be used exclusively as a facing material, but not in any way a structural one.

Dimensions (edit)

Among all the assortment of corrugated sheets presented by manufacturers, the most widespread are sheets with a thickness of 5-6 mm. The width of which rolled products can vary from 600 to 2200 mm, and the length from 1.4 to 8 m. Sheets with dimensions of 3x1250x2500 and 4x1500x6000 mm are in high demand. A slightly less common corrugation made of aluminum and stainless steel is usually made in smaller thicknesses, their base height varies from 1 to 2.3 mm. Thicker corrugated steel is made from austenitic steels, but it is rarely used.

Some manufacturing enterprises, in order to increase the demand for their products, provide a service for the production of corrugated sheet metal of non-standard sizes. But in this case, the parameter must necessarily be a multiple of the standards established by GOST. The mass of one square meter of corrugated sheet directly depends on the type of alloy used, as well as the height of the corrugation and the type of pattern. So, a canvas with a thickness of 5 mm with a height of up to 2 mm and with a steel density of 7850 kg / sq. m, depending on the pattern, has the following weight:

- rhombus - 42 kg / m2;

- lentils - about 45 kg / m2.

The riffle height is considered an important characteristic of any rolled product. Its thickness should not exceed 30% of the total thickness of the iron material. Most often it is 1/10 of the thickness of the metal sheet.

Application

Due to its exceptional technical and operational parameters, corrugated sheet is in demand in a wide range of spheres and areas. It gained great popularity when creating coatings with anti-slip characteristics, since the use of such rolled products significantly reduces the risk of injury. In this regard, corrugated steel is used for laying floors on structures such as:

- slings;

- stairs;

- gangway;

- steps;

- walk.

The use of corrugated steel is especially important in cases where the facility is operated in the open air, being unprotected by any canopy from rain and snow. The use of such a rental allows you to achieve the maximum degree of safety and a high level of comfort, regardless of the season. It is used:

- oil and gas industry;

- mine systems;

- power and hydroelectric power stations;

- construction;

- improvement of territories;

- manufacturing firms;

- design and architecture;

- production of metal containers within the framework of agriculture;

- as a bottom for containers, especially when it is necessary to transport fragile goods.

The corrugated sheet is indispensable for installing roofs, iron doors, as well as for creating ramps, fences and other fences. It is used as a basis for plastering work. The advantage of grooved rolled products is obvious - this type of steel sheet allows you to make the process of creating metal structures and metal objects faster, cheaper and more reliable. At the same time, cost reduction is achieved due to the refusal to perform specialized measures aimed at improving the operational characteristics of the coating and increasing safety parameters.

With the help of this rolled metal, compliance with the safety regulations of industrial workers in enterprises of various industries is ensured. Working on such a surface completely eliminates slipping of the shoes. In addition, the low cost of the corrugated sheet is very attractive for manufacturers. Thus, the combination of special technological characteristics and budgetary efficiency has led to the fact that the demand for corrugated sheet steel is growing steadily these days.

About what corrugated sheets are and where they are used, see below.

The comment was sent successfully.