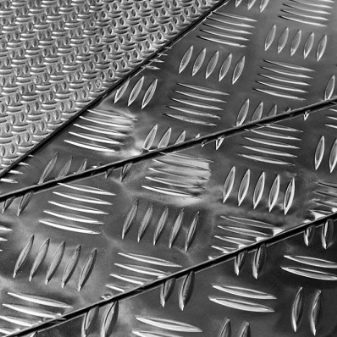

All about corrugated sheets "lentils"

Corrugated sheet "lentil" is now increasingly used in construction or as a finishing material. The peculiarity of such sheet products is that one side is flat, and the other is covered with a convex pattern. This makes the material resistant to abrasion and mechanical stress.

Features of production

According to official requirements, boiling, calm or semi-calm carbon steels as well as stainless steels can be used for the production of corrugated sheets with a simple "lenticular" pattern.... Its strength and cost depend on the choice of material. Most often, corrugated sheets are made of durable AISI 304 or 09G2S steel. In some cases, aluminum is also used in the work. The production process of finely grooved metal products consists of several main stages.

- Creation of metal ingots weighing up to three tons.

- Preparation of material for further rolling.

- Application of patterns to the surface. At this stage, volumetric elements are created on the surface of the prepared sheets by hot rolling. The second side of the material remains smooth and even.

- Final finishing of the material. The specifics of this process depend on the type of end product and the type of alloy used. Usually, the final finish helps to make the material stronger and more durable.

At the end of the work on the surface of the corrugated metal there should be no cracks, rolling caps and rolled bubbles. Finished galvanized sheets can be covered with only subtle ripples or small imprints.

Main characteristics

The standard width of hot rolled "lentil" sheets can vary between 60.6-220 centimeters. In this case, the length of the product can be from 140 to 800 centimeters. Its thickness can also be different. There are products with a thickness of 2 mm, 4 mm, 5 mm, 6 mm, 8 mm. The standard size of "lentils" on the surface of the material is 3.66 millimeters, its height is not less than 0.5 millimeters. The weight of a metal product covered with curly patterns is in the range of 20-96.8 kilograms per 1 m2.

The most popular among buyers are copies with a size of 1500x3000 mm. Most suppliers can also find products in the size of 3x240x1500 and 1200x1500x3 mm. But there are also more non-standard copies on sale. For example, products with dimensions 3x1250x2500, 4x250x1000 and 8x1500x6000 mm. In general, at the request of the customer, some companies can produce metal products in other sizes.

All sheets with such corrugation have the following characteristics.

- Resistant to temperature extremes... Therefore, they can be used in cold regions with harsh winters. They are not afraid of exposure to too high a temperature.

- Corrosion resistant. Strong and wear-resistant metal sheets have a long service life.

- Easy to use. Large sheets are easy to assemble. The installation process does not take much time.

- Eco-friendly and hygienic... Therefore, they are absolutely safe for people, they can be used at home and in enterprises.

- Availability... Corrugated finishing materials are inexpensive. Therefore, it is really profitable to buy them.

It is worth noting that the finished products look attractive, they can be safely used for finishing buildings or arranging fences.

Species overview

Corrugated sheets differ in the nature of the material processing.

- Annealed... The annealing process involves heating the sheet at a high temperature and slowly cooling the material. This procedure helps to increase the plasticity of the product. Annealing can be carried out both before rolling and at the end of all work. The marking of such sheets contains the letter "M".

- Cold-worked... This procedure allows the alloy to be compacted. In the process, the metal is under high pressure. Thanks to this, it becomes more durable. The stronger the pressure, the denser the sheet is. Hard-worked sheets are actively used in construction. It should be remembered that they cannot be bent and cooked. All this can lead to cracks on the surface. Sheets that have undergone such processing are marked with the letter "H".

- Semi-ready... Such specimens differ from the previous ones in that less pressure is exerted on them during processing. Because of this, they are less durable and more plastic. Such products bend well. They are also often used in construction. The marking by which such sheets can be identified is "A2".

- Hardened... The quenching procedure involves rapidly cooling the sheets after preheating. It increases the strength of the material. But the result is not immediately noticeable.

You need to choose the right materials, focusing on your needs and the characteristics of the operation of the material.

Applications

Durable and abrasion-resistant sheets are now actively used in many areas.

- Roofing device. In construction, "lentil" metal sheets are often used to protect the roof. The material can easily withstand the pressure of wet snow. It does not deteriorate under the influence of rain and hail, it has an attractiveness. Corrugated sheets are easy to clean. Therefore, it is very easy to care for them. Such finishing materials are used for the arrangement of structures and non-residential buildings.

- Flooring... In industrial buildings, saunas and swimming pools, the material is often used for flooring. This is due to the fact that its surface is not slippery. In addition, the sheets are laid on ramps and floors in places where many people walk. After all, this type of material is characterized by increased strength, and wears out slowly.

- Construction of fences. Sheets with such a three-dimensional pattern look pretty attractive. Therefore, they are often used in the construction of fences and other exterior elements. Sheets are also used to decorate walls and create partitions. It is worth remembering that if products made of plain steel that do not have anti-corrosion properties are used outdoors, any protective coating must be applied to their surface. But this can be avoided by choosing stainless steel specimens.

- Car body finishing. Most often, such materials are used for finishing large vehicles used for cargo transportation or outdoor trips. They are also used to create water transport.

- Agricultural industry... Corrugated material is often used to make various containers for storing grain and hay. In addition, they are used for the improvement of various premises on farms.

Single groove sheets are also used in the mining and oil industries. There they are actively used to equip platforms, in mines and at production sites. The use of such sheets significantly reduces domestic injuries in the workplace and increases productivity.

Transport and storage

It is recommended to store corrugated steel sheets in dry rooms. If this is not possible, the material is stacked on pallets and left in open areas under a canopy. To prevent the metal from rusting, it is recommended to build gaskets between the sheets.

All types of transport can be used to transport these materials.The main thing is to adhere to certain rules.

- If materials for construction and decoration are transported in large quantities, it is important to stack products of the same brand, thickness and length on separate pallets.... For reliability, they are attached to the pallet with metal straps. Corrugated products will not be damaged or deformed if properly packaged.

- It is forbidden to transport products in open transport over a distance of more than 200 km.

- Do not allow moisture to enter the surface of the sheets. If the sheets on the pallet remain wet for a long time, in the future this will lead to rust on the surface of the material. To prevent this from happening, the sheets are recommended to be transported in closed transport, or wrapped in a layer of special protective film.

In general, corrugated "lentil" steel sheets are used both in the industrial field and at home. They are strong, durable and durable. Therefore, it is really profitable to buy and use such products.

The comment was sent successfully.